In short, PTFE V-Rings are high-performance seals used for demanding dynamic applications. Their primary uses are in sealing rotary shafts, reciprocating pistons, high-speed turbo machinery, and within critical hydraulic and pneumatic systems where chemical exposure or extreme temperatures are a concern.

The core reason for selecting PTFE V-Rings is their unique combination of properties. No other single material offers their level of chemical inertness, wide temperature tolerance, and extremely low friction, making them the solution for sealing moving parts in the most aggressive environments.

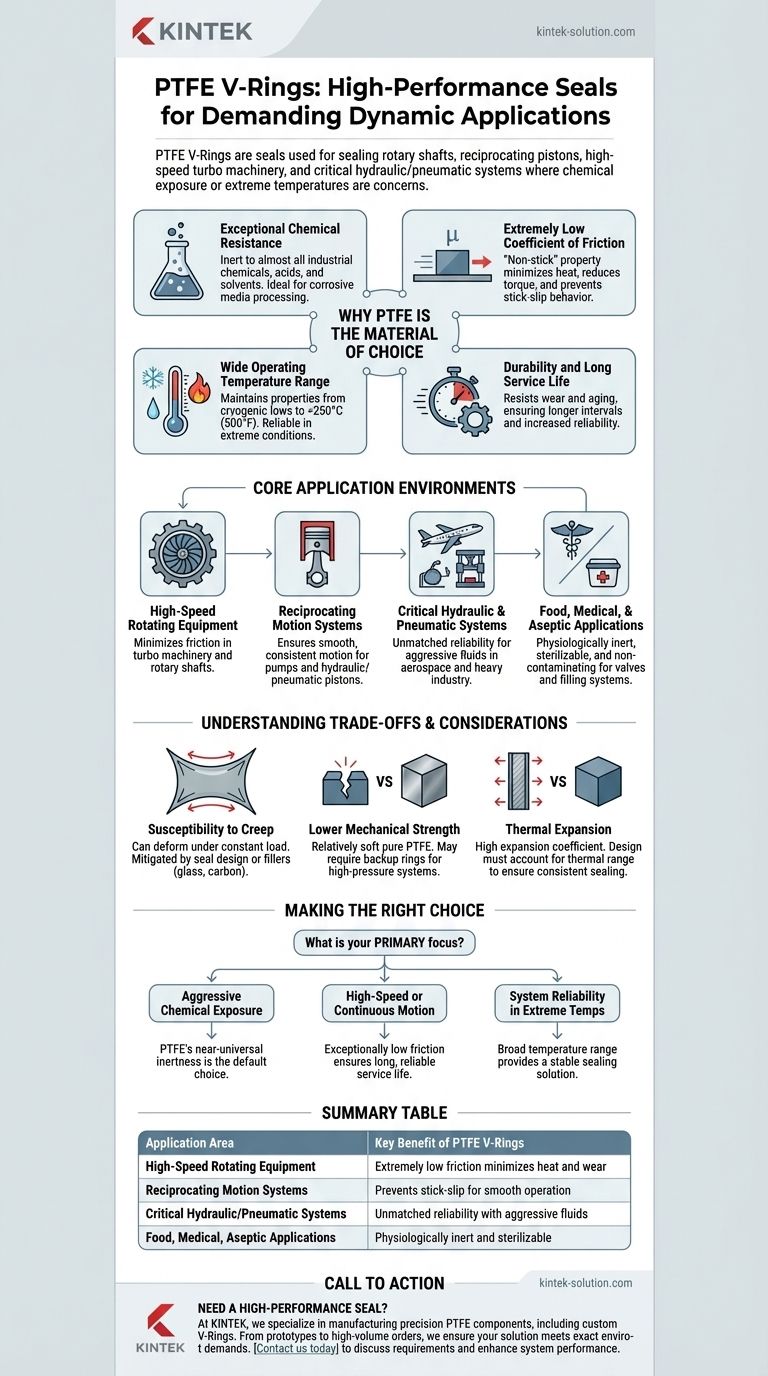

Why PTFE is the Material of Choice for Demanding Seals

To understand the applications of PTFE V-rings, we must first understand the fundamental properties of the material itself. The "why" behind its selection reveals its ideal use cases.

Exceptional Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals, acids, and solvents. This makes it an essential choice for seals in chemical processing equipment, pumps, and valves where exposure to corrosive media would degrade other materials.

Extremely Low Coefficient of Friction

Known for its famous "non-stick" properties, PTFE has one of the lowest coefficients of friction of any solid material. This is critical for V-rings used in dynamic applications, as it minimizes heat generation, reduces torque requirements, and prevents stick-slip behavior in reciprocating pistons.

Wide Operating Temperature Range

PTFE maintains its properties across a vast temperature spectrum, from cryogenic lows to highs exceeding 250°C (500°F). This allows PTFE V-rings to function reliably in machinery that experiences significant temperature fluctuations, such as in aerospace or industrial manufacturing.

Durability and Long Service Life

The combination of chemical stability and low friction results in a highly durable seal. It resists wear and aging, leading to longer service intervals and increased reliability in critical systems where failure is not an option.

Core Application Environments for PTFE V-Rings

These fundamental properties make PTFE V-rings the preferred solution in several specific, high-stakes environments.

High-Speed Rotating Equipment

In applications like turbo machinery and rotary shafts, minimizing friction is paramount. The self-lubricating nature of PTFE allows these seals to handle high rotational speeds without overheating or premature wear, which would be a significant risk with traditional rubber seals.

Reciprocating Motion Systems

For pistons in pumps and hydraulic/pneumatic cylinders, smooth, consistent motion is key. PTFE V-rings provide a reliable seal that reduces drag and eliminates the jerky, stick-slip motion that can occur with other materials, ensuring precise and efficient operation.

Critical Hydraulic and Pneumatic Systems

In sectors like aerospace and heavy industry, seal failure can have catastrophic consequences. PTFE V-rings are specified for their unmatched reliability when sealing aggressive hydraulic fluids or operating in high-temperature pneumatic systems.

Food, Medical, and Aseptic Applications

Because PTFE is physiologically inert and can be sterilized, it is often used in valves and filling systems for food, beverage, and medical applications. The material does not contaminate the media it contacts, ensuring purity and safety.

Understanding the Trade-offs and Considerations

While powerful, PTFE is not a universal solution. An objective assessment requires understanding its limitations.

Susceptibility to Creep

PTFE can be prone to "creep" or cold flow, meaning it can slowly deform over time when under a constant load. This requires careful seal design and, in some high-pressure applications, the use of fillers (like glass, carbon, or bronze) in the PTFE compound to improve resistance to deformation.

Lower Mechanical Strength

Compared to many engineering plastics, pure PTFE is a relatively soft material. In very high-pressure systems, a PTFE V-ring may need to be supported by a backup ring made of a stronger material to prevent the seal from being extruded into the clearance gap.

Thermal Expansion

PTFE has a relatively high coefficient of thermal expansion compared to metals. Engineers must account for this during the design of the seal gland to ensure a proper fit and consistent sealing force across the entire operating temperature range.

Making the Right Choice for Your Application

Selecting the right seal depends entirely on the demands of your specific system.

- If your primary focus is aggressive chemical exposure: PTFE's near-universal chemical inertness makes it the default choice for sealing corrosive media where elastomers would quickly fail.

- If your primary focus is high-speed or continuous motion: The material's exceptionally low friction minimizes wear and heat buildup, ensuring long, reliable service life in dynamic applications.

- If your primary focus is system reliability in extreme temperatures: PTFE's broad operating temperature range provides a stable and predictable sealing solution from cryogenic conditions to high-heat environments.

By understanding these core properties and trade-offs, you can confidently specify PTFE V-rings for your most demanding dynamic sealing challenges.

Summary Table:

| Application Area | Key Benefit of PTFE V-Rings |

|---|---|

| High-Speed Rotating Equipment | Extremely low friction minimizes heat and wear |

| Reciprocating Motion Systems | Prevents stick-slip for smooth operation |

| Critical Hydraulic/Pneumatic Systems | Unmatched reliability with aggressive fluids |

| Food, Medical, Aseptic Applications | Physiologically inert and sterilizable |

Need a high-performance seal for your demanding application?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom V-Rings, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a sealing solution that meets the exact demands of your environment, whether it's chemical resistance, extreme temperatures, or high-speed motion.

Contact us today to discuss your specific requirements and discover how our PTFE components can enhance your system's reliability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments