The primary types of PTFE lined valves are ball, butterfly, plug, check, gate, and globe valves. Each is designed to combine the structural integrity of a metal valve body with the superior chemical and temperature resistance of a Polytetrafluoroethylene (PTFE) liner, making them ideal for handling highly corrosive or pure fluids.

The core purpose of a PTFE lined valve is not simply to exist as another valve type, but to solve a critical industrial problem: safely and reliably controlling corrosive media without the prohibitive cost of using exotic alloy valves. It provides a protective barrier, allowing a standard carbon or stainless steel valve body to perform in applications that would otherwise destroy it.

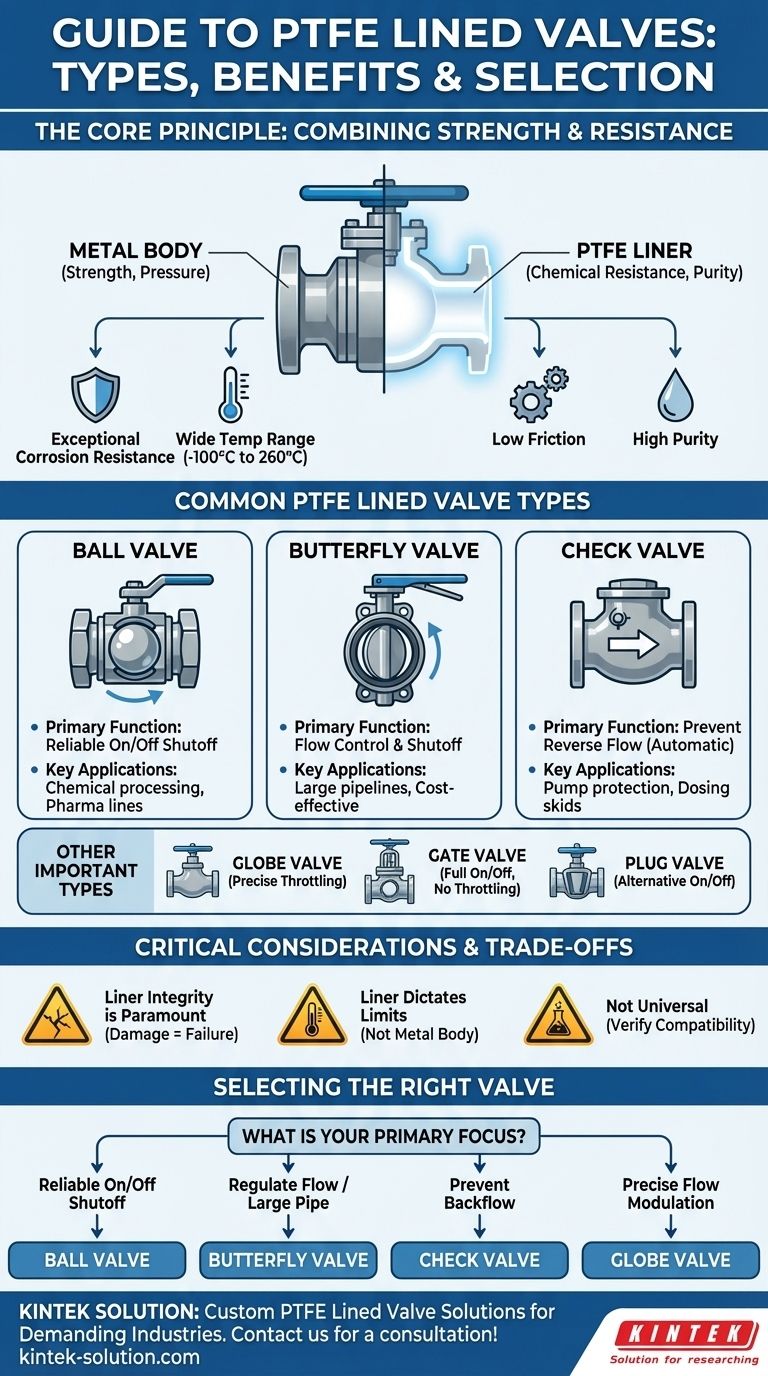

The Core Principle: Why Line a Valve with PTFE?

The decision to use a PTFE lined valve stems from the need to manage aggressive fluids. The design leverages the best properties of two different materials to create a cost-effective and durable solution.

Combining Strength with Resistance

A standard metal valve body (typically cast iron, carbon steel, or stainless steel) provides the mechanical strength required to contain system pressure and connect to the pipeline.

The PTFE liner, which is molded and fitted to all wetted surfaces inside the valve, provides a near-universal barrier against chemical attack. This isolates the structural metal components from the corrosive process fluid.

Key Properties of PTFE

PTFE is selected as a liner material due to its remarkable combination of properties:

- Exceptional Corrosion Resistance: It is inert to nearly all industrial chemicals, including strong acids, alkalis, salts, and organic solvents.

- Wide Temperature Range: It performs reliably at high temperatures (up to 260°C / 500°F) and remains non-brittle at cryogenic temperatures (down to -100°C / -148°F).

- Low Friction: Its extremely low coefficient of friction, one of the lowest of any solid, results in lower torque requirements for operation and reduces wear.

- Purity: PTFE is inherently a pure material, making it suitable for applications in the pharmaceutical, food, and beverage industries where contamination is a concern.

A Breakdown of Common PTFE Lined Valve Types

While many valve designs can be lined, a few types dominate industrial applications due to their operational characteristics.

PTFE Lined Ball Valves: For On/Off Control

These are among the most common lined valves, primarily used for reliable on/off (shutoff) service. The design features a rotating ball with a bore that, when aligned with the pipe, allows flow. A quarter-turn rotates the ball to block the flow path.

Their simple, robust design makes them workhorses in chemical processing, power generation, and pharmaceutical plants for isolating lines carrying corrosive media.

PTFE Lined Butterfly Valves: For Flow Control and Shutoff

A butterfly valve consists of a disc mounted on a central stem within the valve body. A quarter-turn of the stem pivots the disc to either block the flow or position it at an angle to regulate the flow rate.

Lined butterfly valves are valued for being lightweight, cost-effective, and suitable for both shutoff and throttling/flow control applications. They are frequently used to control large volumes of corrosive fluids.

PTFE Lined Check Valves: For Preventing Backflow

Unlike the other types, check valves are automated and require no external actuation. They are designed to allow fluid to flow in only one direction.

A PTFE lined check valve is critical in systems like chemical dosing skids or compressed gas units where reverse flow could damage pumps, contaminate upstream processes, or create a safety hazard.

Other Important Types: Gate, Globe, and Plug Valves

While less detailed in common references, PTFE lined versions of gate, globe, and plug valves also serve specific functions.

- Plug Valves offer similar on/off functionality to ball valves.

- Gate Valves are designed for full-on or full-off service and are not ideal for throttling.

- Globe Valves are designed specifically for precise flow regulation (throttling).

Understanding the Trade-offs and Considerations

While highly effective, PTFE lined valves are not a universal solution. Understanding their limitations is key to successful implementation.

The Importance of Liner Integrity

The entire protective function of the valve depends on the quality and integrity of the PTFE liner. Any scratch, perforation, or improper installation that exposes the metal body to the process fluid will lead to rapid corrosion and valve failure.

Temperature and Pressure Limitations

The operational limits of a lined valve are dictated by the liner, not the metal body. While the steel body can handle high pressures, the PTFE liner has a specific pressure-temperature rating that cannot be exceeded without risking liner collapse or deformation.

Not a Universal Solution

While PTFE is resistant to most chemicals, it is not invincible. It can be attacked by rare substances like molten alkali metals and certain elemental fluorine compounds. Always verify chemical compatibility with your specific process fluid, temperature, and pressure.

Selecting the Right Valve for Your Application

Choosing the correct lined valve requires matching the valve's function to your system's primary goal.

- If your primary focus is reliable on/off shutoff of a corrosive line: A PTFE lined ball valve is the industry standard and most robust choice.

- If your primary focus is regulating flow or you need a lightweight shutoff valve for a large pipeline: A PTFE lined butterfly valve offers excellent control and cost-effectiveness.

- If your primary focus is protecting equipment from damaging reverse flow: A PTFE lined check valve is the essential, automatic solution.

- If your primary focus is precise flow modulation: A PTFE lined globe valve is designed specifically for this throttling purpose.

Ultimately, selecting the right lined valve is a process of matching the valve's inherent design function to your specific operational need, all while leveraging the protective power of PTFE.

Summary Table:

| Valve Type | Primary Function | Key Applications |

|---|---|---|

| Ball Valve | Reliable On/Off Shutoff | Chemical processing, pharmaceutical lines |

| Butterfly Valve | Flow Control & Shutoff | Large volume pipelines, cost-effective solutions |

| Check Valve | Prevent Reverse Flow (Automatic) | Chemical dosing skids, pump protection |

| Globe Valve | Precise Flow Regulation (Throttling) | Systems requiring accurate flow control |

| Gate Valve | Full On/Off Service (Not for Throttling) | Isolation in fully open/closed systems |

| Plug Valve | On/Off Service (Similar to Ball Valve) | Alternative to ball valves for shutoff |

Need a Custom PTFE Lined Valve Solution?

Choosing the right valve is critical for the safety and efficiency of your process. KINTEK specializes in manufacturing high-precision PTFE components, including custom-fabricated lined valves, seals, liners, and labware.

We serve demanding industries like semiconductor, medical, laboratory, and industrial processing. Whether you need a prototype or a high-volume order, our expertise ensures you get a valve that delivers superior chemical resistance, durability, and performance.

Let us help you protect your system from corrosion. Contact our experts today for a consultation on your specific application requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are some challenges in CNC machining Teflon? Mastering Material Instability for Precision Parts

- How do PTFE seals help in reducing maintenance costs for ball valves? Slash Downtime & Boost Reliability

- In which industries are PTFE mill-type envelope gaskets applied? Ensure Leak-Free Sealing in Demanding Environments

- What are some common grades of PTFE used in fabrication? Choose the Right Material for Your Application

- What temperature range can PTFE-lined butterfly valves withstand? Ensuring Safe & Reliable Operation

- What are the advantages of Teflon bearings? Low-Friction, Maintenance-Free Performance for Demanding Environments

- What are PTFE reducing flanges used for? Connect Pipes of Different Sizes with Superior Chemical Resistance

- What material is replacing carbon in seals and piston rings, and why? PTFE's Superior Durability & Lifespan