To be direct, PTFE seals reduce maintenance costs for ball valves by fundamentally improving the valve's reliability and extending its operational life. Their unique combination of an extremely low friction coefficient, self-lubricating properties, and exceptional chemical resistance means the valve is far less likely to wear out, seize, or fail from corrosion. This translates directly into fewer maintenance interventions, less downtime, and lower labor costs over the life of the equipment.

The primary cost saving from PTFE seals comes not from the material itself, but from the prevention of failure. By engineering away common maintenance triggers like lubrication and corrosion, you significantly reduce the frequency of both planned and unplanned downtime.

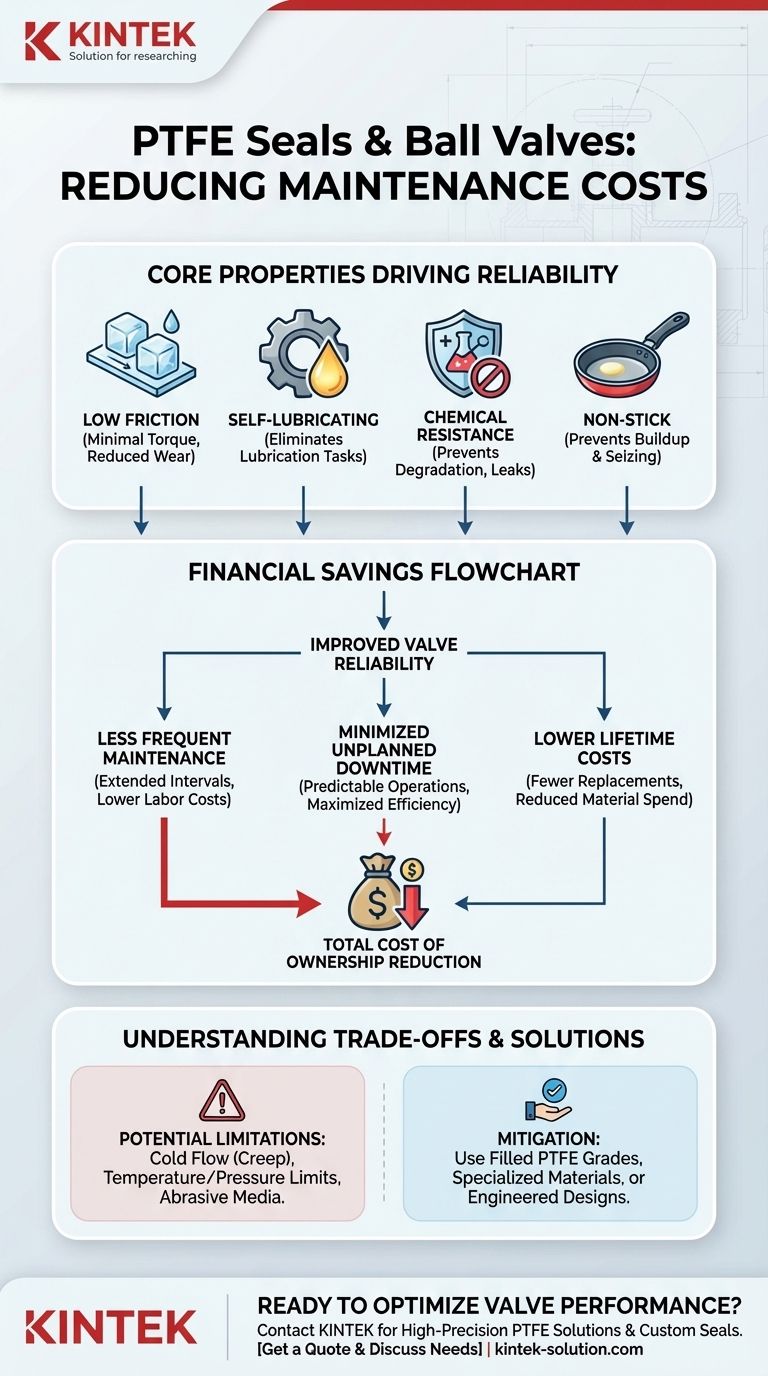

The Core Properties Driving Reliability

To understand the financial impact, we must first look at the material science. PTFE's value in ball valves stems from four key characteristics that work together to create a robust, low-maintenance sealing solution.

Eliminating Frictional Wear

The coefficient of friction for PTFE is one of the lowest of any solid material, comparable to wet ice on wet ice. This means the torque required to open and close the valve is minimal.

This low-friction operation dramatically reduces wear and tear on both the seal and the ball surface, which are the primary moving contact points. Less wear means a longer and more predictable service life.

The Power of Self-Lubrication

PTFE's molecular structure gives it a "waxy" or slippery feel, making it inherently self-lubricating.

This property completely eliminates the need for external lubrication. This removes a recurring maintenance task, saving on labor hours and the cost of lubricants, and also prevents process media contamination from greases.

Resisting Chemical Attack

PTFE is virtually inert and resistant to almost all industrial chemicals and corrosive media.

This chemical resistance ensures the seal will not degrade, swell, or become brittle when exposed to harsh substances. This prevents leaks and catastrophic seal failures that would otherwise require immediate and often costly intervention.

Preventing Sticking and Buildup

PTFE is also known for its non-stick properties, similar to those found in high-end cookware.

In industrial applications, this prevents process media from sticking to or building up on valve components. The valve continues to operate smoothly without seizing, a common failure point in valves handling viscous fluids or particulates.

Translating Physical Properties into Financial Savings

These material properties are not just technical advantages; they have direct and measurable financial benefits that lower the total cost of ownership.

Drastically Reduced Maintenance Frequency

Because PTFE seals resist the primary causes of valve degradation—friction, corrosion, and sticking—the valves simply last longer.

This extends the time between scheduled maintenance overhauls and reduces the likelihood of unexpected failures, directly cutting down on labor and material costs.

Minimizing Costly Unplanned Downtime

Unplanned downtime is often the single greatest expense associated with equipment failure. A valve that fails unexpectedly can halt an entire production line.

The inherent reliability of a well-designed PTFE-sealed valve makes operations more predictable. This stability is critical for maximizing plant efficiency and output.

Lowering Lifetime Labor and Material Costs

The durability of PTFE means fewer seal replacements over the asset's lifespan.

Each avoided replacement cycle saves money on the component itself, the specialized labor required for installation, and the associated operational shutdown.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. An objective assessment requires acknowledging its operational limitations.

Susceptibility to Cold Flow (Creep)

Standard, unfilled PTFE can be prone to "creep" or cold flow, where the material slowly deforms under sustained pressure and temperature.

This can be a concern in high-pressure applications, though it is often mitigated by using filled PTFE grades (e.g., glass- or carbon-filled) which enhance its mechanical strength and resistance to deformation.

Temperature and Pressure Boundaries

PTFE has excellent temperature resistance, but it does have upper and lower limits.

In applications involving extreme temperatures (cryogenic or high heat) or very high pressures, specialized seal materials or engineered valve designs may be necessary to ensure safe and reliable operation.

Abrasive Media Considerations

While non-stick, PTFE is a relatively soft material. In services with highly abrasive slurries, the seal can be subject to mechanical wear.

For these specific applications, a harder seal material or a different valve design might offer a longer service life.

Making the Right Choice for Your Application

Selecting the right valve seal is about matching the material's strengths to your primary operational goal.

- If your primary focus is reliability in corrosive environments: PTFE is an ideal first choice due to its unmatched chemical inertness.

- If your primary focus is reducing routine maintenance labor: The self-lubricating nature of PTFE provides a clear advantage by eliminating an entire category of maintenance tasks.

- If your primary focus is performance in high-pressure or abrasive service: You must evaluate if standard PTFE is sufficient or if a filled grade or an alternative material is required.

Ultimately, leveraging PTFE's unique properties allows you to design for durability, significantly reducing the total cost of ownership for your valve systems.

Summary Table:

| Benefit of PTFE Seals | Impact on Maintenance Costs |

|---|---|

| Low Friction & Self-Lubricating | Reduces wear, eliminates lubrication tasks, extends service life. |

| Exceptional Chemical Resistance | Prevents degradation and failure from corrosive media, avoiding leaks. |

| Non-Stick Properties | Prevents buildup and valve seizing, ensuring smooth operation. |

| Increased Reliability | Drastically reduces frequency of both planned and unplanned downtime. |

Ready to reduce your maintenance costs and improve valve reliability?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and custom labware. Our expertise ensures that your ball valves are equipped with seals that deliver maximum durability and performance, tailored for the demanding environments of the semiconductor, medical, laboratory, and industrial sectors.

By choosing KINTEK, you benefit from:

- Longer Service Life: Our PTFE seals are engineered to resist wear, corrosion, and sticking.

- Reduced Operational Costs: Minimize downtime and eliminate routine lubrication.

- Custom Solutions: We offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact us today to discuss how our PTFE sealing solutions can enhance your valve performance and lower your total cost of ownership.

Get a Quote & Discuss Your Needs

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What benefits does PTFE provide in athletic footwear? Enhancing Performance with Low-Friction & Non-Stick Solutions

- How do PTFE rotary shaft seals perform in high-speed applications? Master High-Speed Sealing with Low Friction

- What are the key properties of Teflon sheets? A Guide to PTFE's Versatility

- What are the two primary grades of PTFE? Virgin vs. Mechanical for Your Application

- How should cooling be managed during Teflon machining? Prevent Warping & Ensure Precision

- What is required for the proper use of PTFE piston seals? Master the Two-Part System for Superior Performance

- What colors are available for custom PTFE grades? Select the Right Color for Performance and Identification

- Why is CNC machining ideal for manufacturing Teflon parts? Unlock Precision Without Compromising Material Integrity