For custom grades of Polytetrafluoroethylene (PTFE), a wide spectrum of colors is available for identification and branding purposes. These include black, gray, red, orange, yellow, green, blue, purple, and brown, in addition to the standard natural white of virgin PTFE.

The key insight is that while many colors are available, the most functionally significant color variations—such as black, gray, or brown—are not merely cosmetic. They are typically a direct result of adding specific fillers to the PTFE to enhance its mechanical properties for demanding applications.

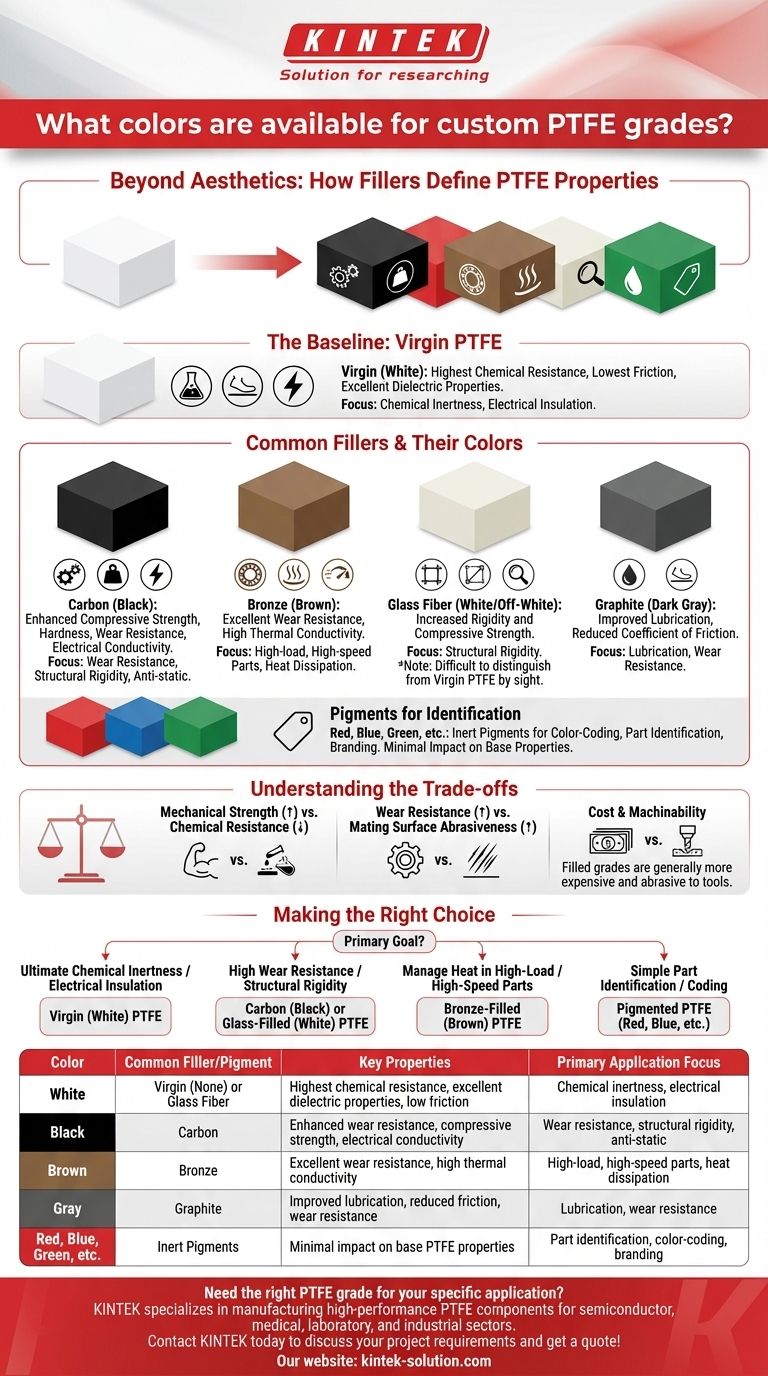

Beyond Aesthetics: How Fillers Define PTFE Properties

The color of a PTFE component often serves as an immediate indicator of its grade and intended use. Understanding the difference between a simple pigment and a performance-enhancing filler is critical for material selection.

The Baseline: Virgin PTFE (White)

Pure, unmodified PTFE is naturally a bright, waxy white. This grade, known as virgin PTFE, offers the highest chemical resistance, lowest coefficient of friction, and excellent dielectric properties.

The Role of Performance-Enhancing Fillers

To overcome some of virgin PTFE's limitations, such as low wear resistance and deformation under load (creep), manufacturers add filler materials. These fillers fundamentally alter the PTFE's characteristics and, in many cases, its color.

Common Fillers and Their Associated Colors

- Carbon (Black): Adding carbon powder results in a black compound. This grade offers enhanced compressive strength, hardness, and wear resistance. It also provides good electrical conductivity, making it suitable for anti-static applications.

- Graphite (Dark Gray): Often combined with other fillers like carbon or glass, graphite improves lubrication, reduces the coefficient of friction, and enhances wear properties, resulting in a dark gray or black material.

- Glass Fiber (White / Off-White): Glass fibers are a common filler used to increase rigidity and compressive strength. Because the filler is white, glass-filled PTFE remains white or off-white, making it difficult to distinguish from virgin PTFE on sight alone.

- Bronze (Brown): Adding bronze powder creates a distinct brown-colored PTFE. This grade offers excellent wear resistance and high thermal conductivity, allowing heat to dissipate quickly in high-speed bearing and wear applications.

Pigments for Identification

Colors like red, blue, and green are typically achieved by adding inert pigments. While they have minimal impact on performance compared to structural fillers, they are invaluable for color-coding parts in complex assemblies, preventing installation errors, or for branding.

Understanding the Trade-offs

Choosing a filled or colored PTFE grade is an exercise in balancing performance requirements. The advantages gained in one area often come with compromises in another.

Mechanical Strength vs. Chemical Resistance

Adding fillers like glass or carbon dramatically improves mechanical properties such as compressive strength and dimensional stability. However, these additives can slightly reduce the exceptional chemical resistance that pure PTFE is known for.

Wear Resistance vs. Mating Surfaces

While carbon and glass-filled grades offer superior wear resistance, they can be more abrasive to softer mating surfaces like aluminum or other plastics. Bronze-filled PTFE is often a better choice for these scenarios.

Cost and Machinability

Filled PTFE grades are generally more expensive than virgin PTFE. Furthermore, abrasive fillers like glass can increase tool wear during CNC machining, which may impact the total cost of a finished part.

Making the Right Choice for Your Goal

Selecting the correct PTFE grade requires aligning the material's properties with the application's primary demand.

- If your primary focus is ultimate chemical inertness or electrical insulation: Choose virgin (white) PTFE for its purity and dielectric strength.

- If your primary focus is high wear resistance and structural rigidity: Carbon-filled (black) or glass-filled (white) PTFE are the ideal choices.

- If your primary focus is managing heat in high-load, high-speed parts: Bronze-filled (brown) PTFE provides the necessary thermal conductivity.

- If your primary focus is simple part identification or coding: Request a pigmented PTFE (red, blue, yellow, etc.) while confirming its base properties meet your needs.

Ultimately, choosing the right material is an informed decision where performance requirements should always guide your selection, with color serving as a useful indicator of those properties.

Summary Table:

| Color | Common Filler/Pigment | Key Properties | Primary Application Focus |

|---|---|---|---|

| White | Virgin (None) or Glass Fiber | Highest chemical resistance, excellent dielectric properties, low friction | Chemical inertness, electrical insulation |

| Black | Carbon | Enhanced wear resistance, compressive strength, electrical conductivity | Wear resistance, structural rigidity, anti-static |

| Brown | Bronze | Excellent wear resistance, high thermal conductivity | High-load, high-speed parts, heat dissipation |

| Gray | Graphite | Improved lubrication, reduced friction, wear resistance | Lubrication, wear resistance |

| Red, Blue, Green, etc. | Inert Pigments | Minimal impact on base PTFE properties | Part identification, color-coding, branding |

Need the right PTFE grade for your specific application?

KINTEK specializes in manufacturing high-performance PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require the chemical purity of virgin PTFE or the enhanced mechanical properties of filled grades, our team provides precision production and custom fabrication from prototypes to high-volume orders.

Let us help you select the optimal material to balance performance, cost, and longevity. Contact KINTEK today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What key offerings are associated with Teflon-encapsulated O-Rings? Beyond the Part to Full-System Support

- Why is PTFE used in chemical transport and storage systems? Unmatched Chemical & Thermal Resistance

- What are the disadvantages of PTFE bushes? Key Limitations for Industrial Applications

- What are the disadvantages of using PTFE O-Rings? When Rigidity and Lack of Elasticity Cause Leaks

- In which industries are machined PTFE parts commonly used? Discover the Essential High-Performance Material

- What are the limitations of PTFE bellows? Understanding Its Mechanical and Chemical Boundaries

- What additional advantages does expanded PTFE offer? Superior Sealing, Stability & Purity for Critical Applications

- How do Teflon bellow mechanical seals enhance equipment efficiency in the pulp and paper industry? Boost Reliability and Cut Costs