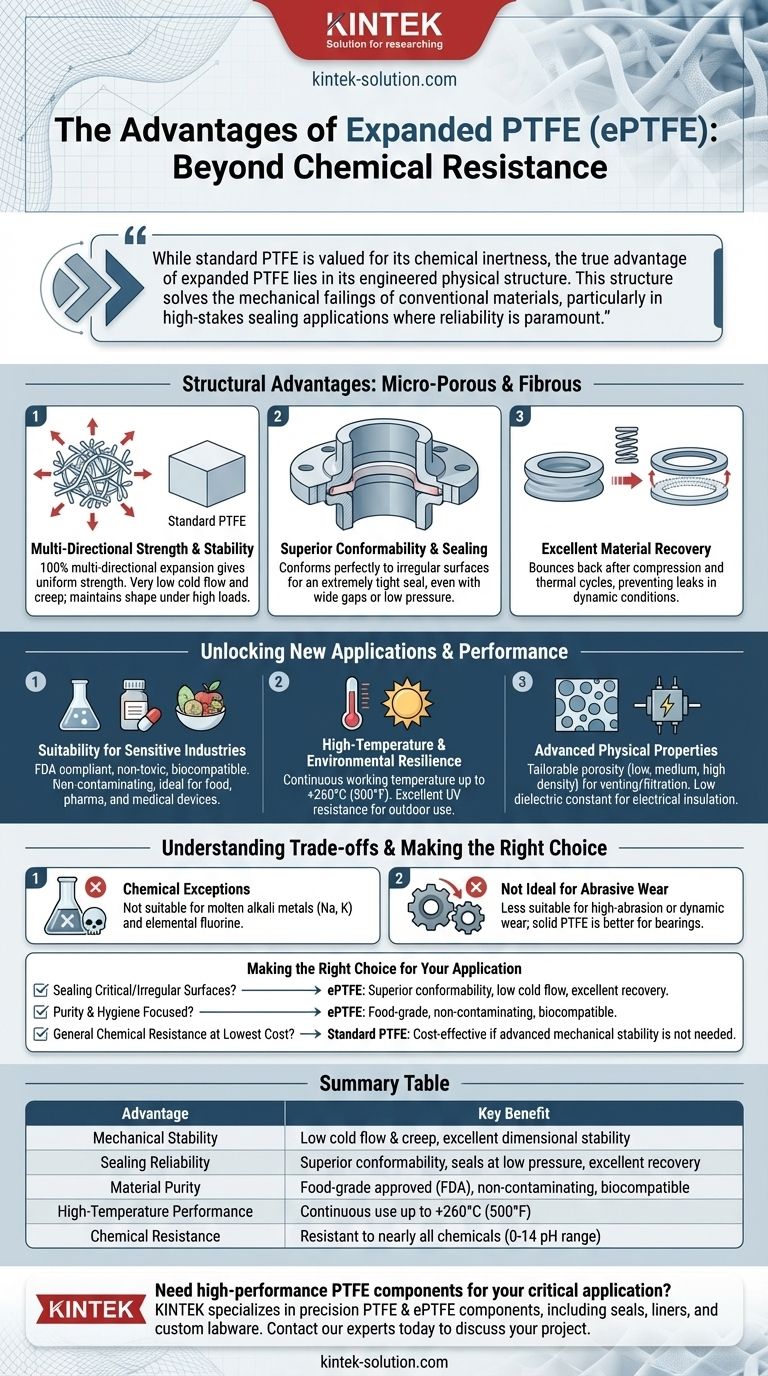

Beyond its known benefits, expanded PTFE (ePTFE) offers significant advantages in mechanical stability, sealing reliability, and suitability for sensitive applications. Unlike standard PTFE, its unique manufacturing process creates a material with exceptional dimensional stability, resistance to cold flow, and the ability to conform to imperfect surfaces. Furthermore, it is food-grade approved, non-contaminating, and possesses excellent recovery properties, making it ideal for demanding industrial environments.

While standard PTFE is valued for its chemical inertness, the true advantage of expanded PTFE lies in its engineered physical structure. This structure solves the mechanical failings of conventional materials, particularly in high-stakes sealing applications where reliability is paramount.

Beyond Chemical Resistance: The Structural Advantage of ePTFE

The core value of ePTFE is not just what it's made of, but how it's made. The expansion process transforms PTFE from a solid plastic into a micro-porous, fibrous material with fundamentally new mechanical properties.

Multi-Directional Strength and Stability

The material is created from 100 percent multi-directionally expanded PTFE. This process gives it uniform strength in all directions.

This structural integrity is why ePTFE has a very low tendency for cold flow and creep, a common failure point for conventional PTFE gaskets. It maintains its shape under high loads and temperature fluctuations.

Superior Conformability and Sealing

The soft, flexible nature of ePTFE allows it to conform perfectly to irregular, scratched, or damaged flange surfaces. This ensures an extremely tight seal even with wide or inconsistent flange gaps.

This property also means it can achieve a watertight seal at very low pressure, reducing the stress on sensitive or fragile flange materials like glass or plastic.

Excellent Material Recovery

ePTFE exhibits outstanding material recovery. After being compressed and subjected to thermal cycles, it bounces back to maintain a secure seal.

This resilience is critical in applications with frequent temperature changes, preventing leaks that would occur as traditional gaskets permanently deform.

Unlocking New Applications and Performance

The unique combination of PTFE's chemical properties and ePTFE's structural enhancements makes it suitable for a wider range of high-performance scenarios.

Suitability for Sensitive Industries

ePTFE is food-grade approved (FDA compliant), non-toxic, and biocompatible. It does not contaminate or discolor end products.

These characteristics make it a preferred material for the food and beverage, pharmaceutical, and medical device industries, where purity is non-negotiable.

High-Temperature and Environmental Resilience

ePTFE maintains its properties at a continuous working temperature of up to +260°C (500°F), among the highest for any fluoroplastic.

It also offers excellent UV resistance, making it suitable for outdoor applications where other polymers would degrade over time.

Advanced Physical Properties

The manufacturing process allows for the creation of ePTFE in different porosity levels (low, medium, and high density). This allows the material to be tailored for specific applications, like venting or filtration.

Additionally, it retains PTFE's low dielectric constant, making it an excellent electrical insulator for specialized electronic components.

Understanding the Trade-offs and Limitations

No material is a universal solution. Understanding the specific limitations of ePTFE is key to using it correctly and avoiding misapplication.

Chemical Exceptions

While resistant to nearly all chemicals across the full 0-14 pH range, ePTFE is not suitable for use with molten alkali metals (like sodium or potassium) and elemental fluorine. These highly reactive substances will attack the material.

Not Ideal for Abrasive Wear

The soft, porous structure that makes ePTFE an excellent sealing material also makes it less suitable for high-abrasion or dynamic wear applications. Solid PTFE or other harder polymers are better choices for bearings or sliding surfaces.

Higher Initial Cost

As a highly engineered specialty material, ePTFE typically has a higher upfront cost than conventional PTFE or other common gasketing materials. Its value is justified by its extended lifespan, reduced maintenance, and prevention of costly leaks in critical systems.

Making the Right Choice for Your Application

Selecting the correct material requires aligning its specific advantages with your primary engineering goal.

- If your primary focus is sealing critical or irregular surfaces: ePTFE's superior conformability, low cold flow, and excellent material recovery make it the definitive choice for a reliable, long-term seal.

- If your primary focus is purity and hygiene: Its food-grade status, non-contaminating nature, and biocompatibility are ideal for applications in the food, pharmaceutical, and medical industries.

- If your primary focus is general chemical resistance at the lowest cost: Traditional solid PTFE may be a more cost-effective solution if you do not require the advanced mechanical stability and sealing performance of ePTFE.

Understanding these distinctions empowers you to select a material that delivers not just performance, but precision and peace of mind.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Mechanical Stability | Low cold flow & creep, excellent dimensional stability |

| Sealing Reliability | Superior conformability, seals at low pressure, excellent recovery |

| Material Purity | Food-grade approved (FDA), non-contaminating, biocompatible |

| High-Temperature Performance | Continuous use up to +260°C (500°F) |

| Chemical Resistance | Resistant to nearly all chemicals (0-14 pH range) |

Need high-performance PTFE components for your critical application?

At KINTEK, we specialize in manufacturing precision PTFE and ePTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get a solution tailored to your exact requirements for superior sealing, stability, and purity.

Contact our experts today to discuss how our PTFE solutions can enhance your project's reliability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What is the function of check valves in water pump systems? Protect Your Pump and Prevent Backflow

- What are PTFE heat press sheets commonly known as? Achieve Flawless Heat Transfer with Teflon Sheets

- What are the design and fitting guidelines for installing PTFE piston rings? Ensure a Leak-Free, Long-Lasting Seal

- How can the right PTFE gasket improve equipment service life? Extend Lifespan with Superior Protection

- What are the different styles of PTFE gasket materials available? Choose the Right Type for Your Application

- What industries commonly use PTFE components? Critical Solutions for Extreme Environments

- What are the key steps in designing PTFE slide bearings for a specific application? Achieve Optimal Performance and Reliability

- What are the thermal properties of PTFE that make it ideal for seals? Ensuring Reliability in Extreme Conditions