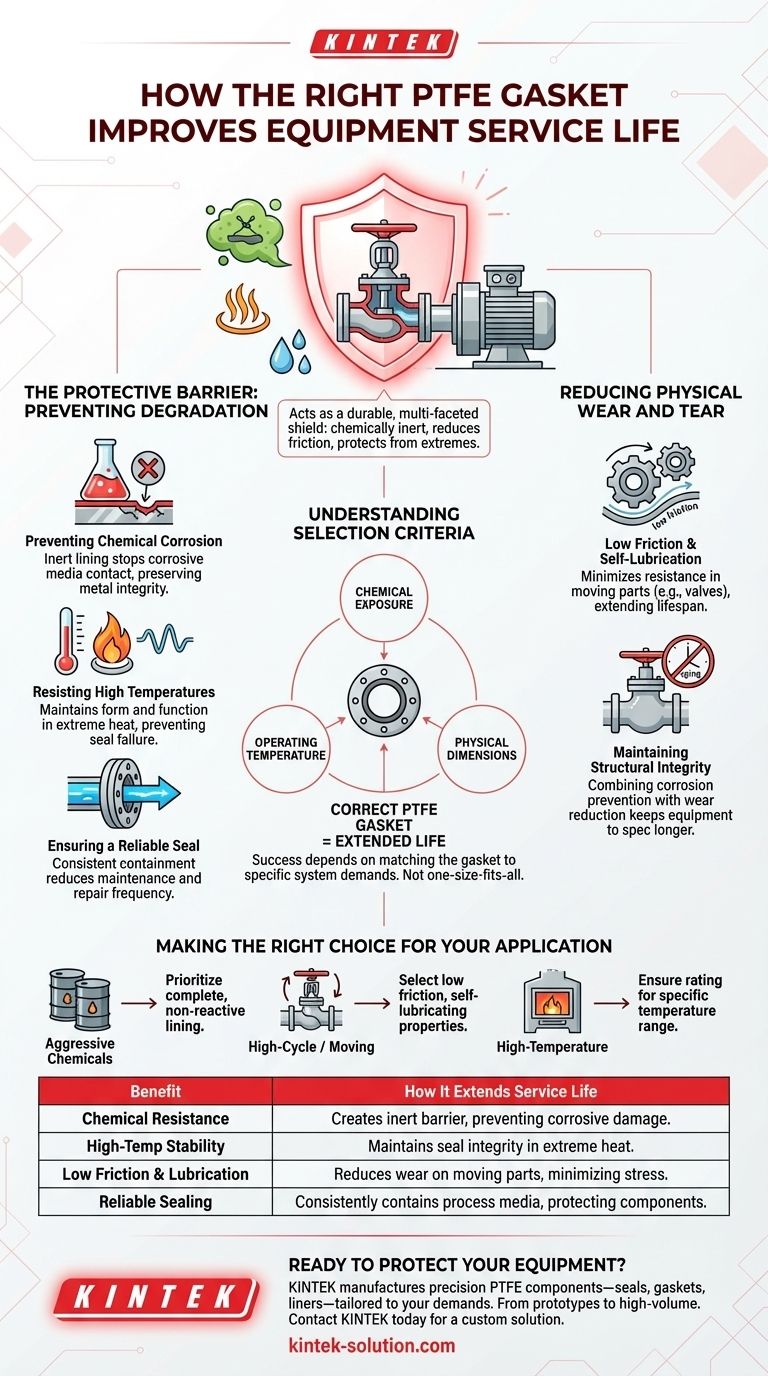

The right PTFE gasket improves equipment service life by acting as a durable, multi-faceted shield. It creates a chemically inert barrier that prevents leaks, reduces physical friction, and protects sensitive internal components from corrosive media and extreme temperatures, directly combating the primary drivers of mechanical failure.

The longevity of your equipment isn't just about the strength of its core components; it's about how well they are protected. PTFE gaskets provide this protection, leveraging unique material properties to prevent the most common causes of failure—corrosion, wear, and leakage—and thereby directly extend operational life.

The Protective Barrier: How PTFE Prevents Degradation

A gasket’s primary role is to seal, but a high-performance PTFE gasket does much more. It isolates the equipment from the harsh conditions of its operating environment, effectively stopping degradation before it can begin.

Preventing Chemical Corrosion

PTFE is renowned for its exceptional chemical resistance. It acts as an inert lining, preventing corrosive media from ever making direct contact with the metal components of equipment like valve bodies or flanges.

This protective barrier is critical. By stopping chemical attacks, the gasket preserves the structural integrity of the metal, preventing the deterioration that leads to leaks and premature failure.

Resisting High Temperatures

Many industrial processes involve high temperatures that can cause lesser materials to degrade, crack, or lose their sealing capability.

PTFE gaskets are engineered to withstand high temperatures, ensuring they maintain their form and function. This stability prevents seal failure and subsequent leakage, which could otherwise damage surrounding components.

Ensuring a Reliable Seal

The core function of preventing leaks is central to extending service life. A reliable seal contains the process media, protecting both the equipment's external surfaces and internal mechanisms from exposure.

This consistent performance reduces the frequency of maintenance cycles and the need for costly repairs or replacements over the equipment's lifetime.

Reducing Physical Wear and Tear

Beyond chemical and thermal protection, PTFE addresses the physical stresses that degrade equipment, particularly in systems with moving parts.

The Impact of Low Friction

PTFE has an extremely low coefficient of friction and self-lubricating properties. This is especially valuable in dynamic applications like ball valves.

The seal's low-friction surface allows moving parts to operate smoothly with minimal resistance. This drastically reduces the physical wear and tear that would otherwise shorten the valve's operational lifespan.

Maintaining Structural Integrity

By combining corrosion prevention with wear reduction, the PTFE gasket helps the entire piece of equipment maintain its original design specifications for a longer period.

The valve, pump, or flange is less prone to aging because the gasket mitigates the root causes of both chemical and mechanical stress.

Understanding the Selection Criteria

The benefits of PTFE are only realized when the correct gasket is chosen for the application. A mismatch between the gasket and the operational environment can lead to premature failure.

Not a One-Size-Fits-All Solution

The term "PTFE gasket" covers a range of products with different properties. The effectiveness of the seal is entirely dependent on matching it to the specific demands of the system.

Key Selection Factors

Three factors are paramount when choosing a gasket: chemical exposure, operating temperature, and physical dimensions. An incorrect choice in any of these areas can compromise the seal and negate the material's protective benefits.

Making the Right Choice for Your Application

Selecting the appropriate PTFE gasket is a direct investment in your equipment's longevity. Base your decision on the most significant stressor in your operational environment.

- If your primary focus is handling aggressive chemicals: Prioritize a PTFE gasket that offers a complete, non-reactive lining to prevent any contact between the media and your equipment's metal components.

- If your primary focus is high-cycle or moving equipment (like valves): Select a PTFE seal known for its low friction and self-lubricating properties to minimize physical wear over millions of cycles.

- If your primary focus is high-temperature operations: Ensure the selected PTFE gasket is rated for your specific temperature range to prevent material degradation and maintain a long-lasting, reliable seal.

Ultimately, choosing the correct PTFE gasket is a strategic decision that enhances the long-term reliability and performance of your critical assets.

Summary Table:

| Benefit | How It Extends Service Life |

|---|---|

| Chemical Resistance | Creates an inert barrier, preventing corrosive media from damaging metal components. |

| High-Temperature Stability | Maintains seal integrity in extreme heat, preventing failure and leakage. |

| Low Friction & Self-Lubrication | Reduces wear on moving parts in valves and pumps, minimizing mechanical stress. |

| Reliable Sealing | Consistently contains process media, protecting internal and external components from damage. |

Ready to protect your equipment and extend its service life?

At KINTEK, we manufacture precision PTFE components—including seals, gaskets, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get the exact PTFE gasket tailored to your application's chemical, temperature, and physical demands, from prototypes to high-volume orders.

Contact KINTEB today for a custom solution that enhances your equipment's longevity and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability