In short, Polytetrafluoroethylene (PTFE) is a critical material in nearly every high-performance industry. Its components are essential in sectors ranging from medical and pharmaceutical manufacturing to aerospace, semiconductor fabrication, chemical processing, and automotive engineering. This widespread adoption is not accidental; it is a direct result of PTFE's uniquely powerful combination of material properties that solve problems other plastics cannot.

The core reason for PTFE's versatility is its ability to simultaneously resist aggressive chemicals, withstand extreme temperatures, provide excellent electrical insulation, and offer an exceptionally low coefficient of friction. No single industry dominates its use; rather, it is the go-to problem-solver for extreme engineering challenges across many fields.

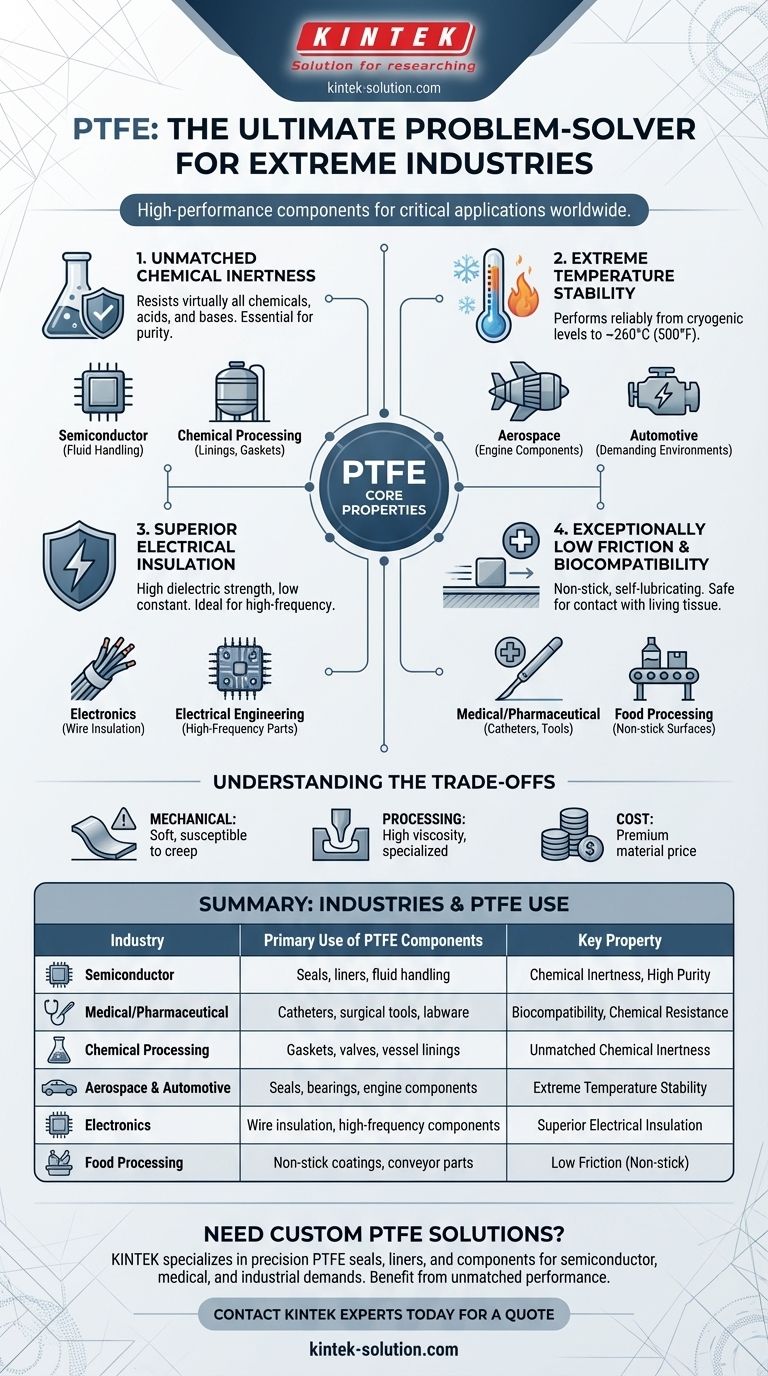

The Core Properties Driving PTFE Adoption

To understand where PTFE is used, you must first understand why it is chosen. Its value comes from a unique set of four characteristics that are rarely found together in a single material.

Unmatched Chemical Inertness

PTFE is virtually inert and does not react with the vast majority of industrial chemicals, acids, and bases. This makes it an essential material for containing and transporting corrosive or high-purity fluids.

This property is the primary reason for its use in chemical processing (vessel linings, gaskets, valves) and semiconductor manufacturing where fluid purity is paramount.

Extreme Temperature Stability

PTFE maintains its properties across a very wide temperature range, performing reliably in applications from cryogenic levels up to approximately 260°C (500°F).

This thermal resilience makes it indispensable for high-temperature applications in aerospace (jet engine components, fittings) and demanding automotive environments.

Superior Electrical Insulation

PTFE is an outstanding electrical insulator with a high dielectric strength and low dielectric constant. It resists tracking and arc-over, making it ideal for high-frequency applications.

This is why it is widely used in electronics and electrical engineering for high-performance wire insulation, cable jacketing, and insulating components in semiconductor fabrication.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, a property often compared to wet ice on wet ice. This inherent lubricity means it is excellent for applications where parts must slide against each other.

This "non-stick" characteristic is key in food processing (conveyor rollers, non-stick coatings) and for self-lubricating automotive parts like seals, gaskets, and bearings.

Biocompatibility and High Purity

In its virgin state, PTFE is non-toxic and biocompatible, meaning it is not harmful to living tissue. This allows it to be used for devices that come into contact with the human body.

This property, combined with its chemical inertness, makes it a foundational material in the medical and pharmaceutical industries for catheters, surgical instruments, and high-purity fluid transfer systems.

Understanding the Trade-offs

While PTFE is a high-performance material, it is not a universal solution. An objective assessment requires understanding its limitations.

Mechanical Limitations

PTFE is a relatively soft material. It is susceptible to creep, or "cold flow," where the material deforms permanently under a sustained load. It is not suitable for structural applications requiring high rigidity or load-bearing strength without reinforcement (e.g., glass or carbon fillers).

Processing Challenges

Unlike common thermoplastics, PTFE cannot be processed using conventional melt-extrusion or injection molding techniques due to its extremely high melt viscosity. It requires specialized processes like compression molding and sintering, which can increase manufacturing complexity and cost.

Cost Considerations

PTFE is a premium, high-performance fluoropolymer. Its cost is significantly higher than that of commodity plastics like polyethylene or polypropylene. Its use is therefore typically reserved for applications where its unique properties are a strict requirement.

Making the Right Choice for Your Application

Selecting the right material requires aligning its properties with your primary engineering goal.

- If your primary focus is handling aggressive chemicals or high-purity fluids: PTFE's chemical inertness makes it an industry-standard choice for seals, linings, and valves.

- If your primary focus is reducing friction in dynamic, low-load applications: PTFE's exceptional lubricity makes it a top candidate for non-stick surfaces, bearings, and seals.

- If your primary focus is reliable electrical insulation in high-frequency or high-temperature environments: PTFE offers an unmatched combination of dielectric strength and thermal stability.

- If your primary focus is structural strength at a low cost: You should evaluate other engineering plastics or composites, as this is a fundamental weakness of unfilled PTFE.

Ultimately, PTFE is the material of choice when performance in extreme environments is a non-negotiable requirement.

Summary Table:

| Industry | Primary Use of PTFE Components | Key PTFE Property Utilized |

|---|---|---|

| Semiconductor | Seals, liners, fluid handling | Chemical Inertness, High Purity |

| Medical/Pharmaceutical | Catheters, surgical tools, labware | Biocompatibility, Chemical Resistance |

| Chemical Processing | Gaskets, valves, vessel linings | Unmatched Chemical Inertness |

| Aerospace & Automotive | Seals, bearings, engine components | Extreme Temperature Stability |

| Electronics | Wire insulation, high-frequency components | Superior Electrical Insulation |

| Food Processing | Non-stick coatings, conveyor parts | Low Friction (Non-stick) |

Need high-performance PTFE components tailored to your industry's extreme demands?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures your application benefits from PTFE's unmatched chemical resistance, thermal stability, and low friction.

Contact our experts today to discuss your specific requirements and get a quote for reliable, custom-fabricated PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support