To put it simply, a PTFE heat press sheet is most commonly known as a Teflon sheet. This name has become the standard term used across various industries, from textile customization and sublimation printing to projects involving heat transfer vinyl (HTV).

While the name "Teflon sheet" is widely used, understanding the properties of its core material, PTFE, is what truly matters. This material provides the critical non-stick, heat-resistant barrier essential for protecting both your project and your equipment during any heat application.

What is a PTFE Sheet?

PTFE sheets are a fundamental tool in any heat transfer process. Their value comes directly from the unique properties of the material they are made from.

The Core Material: PTFE

The sheet is crafted from PTFE, which stands for polytetrafluoroethylene. This synthetic fluoropolymer is engineered to have a unique combination of highly valuable characteristics for high-temperature work.

Why It's Called a "Teflon" Sheet

"Teflon" is the most recognizable brand name for PTFE. Much like "Kleenex" for tissues, the brand name has become a generic term used to describe any heat press sheet made from this material.

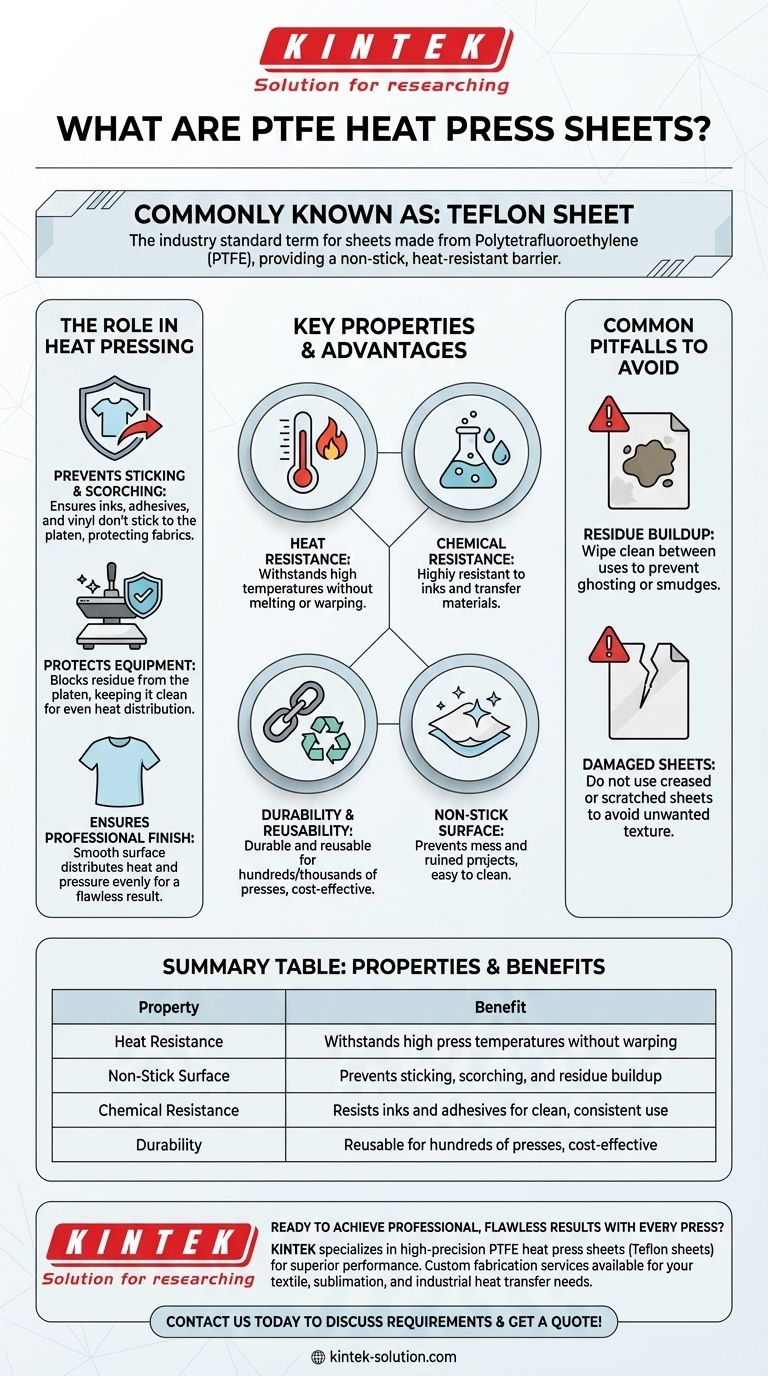

The Role of a PTFE Sheet in Heat Pressing

A PTFE sheet acts as a protective shield between the hot upper platen of your heat press and your garment or substrate. Its function is straightforward but critical for achieving a professional result.

Prevents Sticking and Scorching

Its primary benefit is its exceptional non-stick surface. This ensures that inks, adhesives, and vinyl do not stick to your heat platen, preventing messes and ruined projects. It also protects delicate fabrics from direct contact that could cause scorching or shiny marks.

Protects Your Equipment

By blocking any residue from reaching the platen, the sheet keeps your expensive heat press clean and in optimal working condition. A clean platen is essential for even heat distribution on future projects.

Ensures a Professional Finish

The smooth surface helps distribute pressure and heat evenly across the transfer, resulting in a clean, consistent application without unwanted texture or marks.

Key Properties and Their Advantages

The effectiveness of a PTFE sheet is rooted in four key properties that make it uniquely suited for heat transfer applications.

Heat Resistance

PTFE can withstand the high temperatures required for sublimation and HTV application without melting, warping, or degrading.

Chemical Resistance

This material is highly resistant to chemicals, which is a key advantage in industrial settings and ensures it won't react with inks or transfer materials.

Durability and Reusability

PTFE sheets are not single-use items. They are durable, easy to wipe clean, and can be used for hundreds or even thousands of presses, making them highly cost-effective.

Common Pitfalls to Avoid

While incredibly useful, getting the best results requires proper use. Missteps can compromise an otherwise perfect project.

Residue Buildup

Always wipe the sheet clean between uses. A small amount of ink or adhesive residue left on the sheet can be accidentally transferred to your next project, causing "ghosting" or smudges.

Using a Damaged Sheet

Do not use a sheet that is creased, torn, or heavily scratched. Any imperfection in the sheet's surface can potentially transfer an unwanted texture to your final product.

Making the Right Choice for Your Project

Using a protective sheet is non-negotiable for quality work. Understanding its purpose helps you apply it correctly.

- If your primary focus is protecting your garment and press: A PTFE (Teflon) sheet is the industry standard for creating a reusable, non-stick barrier.

- If your primary focus is professional, clean results: Using a PTFE sheet is critical for preventing scorching, sticking, and unwanted residue on your final product.

- If your primary focus is cost-effectiveness: The durability and reusability of PTFE sheets make them a far more economical long-term choice than single-use alternatives like parchment paper.

Ultimately, this simple sheet is a key tool that provides the control and protection necessary to achieve flawless heat transfer results every time.

Summary Table:

| Property | Benefit |

|---|---|

| Heat Resistance | Withstands high press temperatures without warping |

| Non-Stick Surface | Prevents sticking, scorching, and residue buildup |

| Chemical Resistance | Resists inks and adhesives for clean, consistent use |

| Durability | Reusable for hundreds of presses, cost-effective |

Ready to achieve professional, flawless results with every press?

KINTEK specializes in manufacturing high-precision PTFE components, including durable, reusable heat press sheets (Teflon sheets) designed for superior non-stick performance and heat resistance. Whether you're in the textile, sublimation printing, or industrial heat transfer industry, our custom fabrication services ensure you get the exact specifications you need—from prototypes to high-volume orders.

Protect your equipment and elevate your projects with KINTEK's reliable PTFE solutions. Contact us today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main components constructed from PTFE in these valves? Ensure Ultimate Purity and Chemical Resistance

- How do expanded PTFE gaskets compare to rubber or plastic seals in terms of lifespan? Last Up to 7x Longer

- What are spring-energized PTFE seals and how do they work? Achieve Leak-Proof Reliability in Extreme Conditions

- What are some polymers similar to PTFE? Discover Melt-Processible Fluoropolymer Alternatives

- What should be considered when choosing a manufacturer for PTFE-lined bearings? Ensure Long-Term Reliability and Performance

- Where are PTFE valve seat rings commonly used? Ensuring Purity and Reliability in Critical Processes

- Why are PTFE envelope gaskets preferred in pharmaceutical and food industries? Ensure Absolute Product Purity

- What are some key characteristics of Teflon and PTFE that make them suitable for building construction? Enable Durable, Low-Maintenance Structures