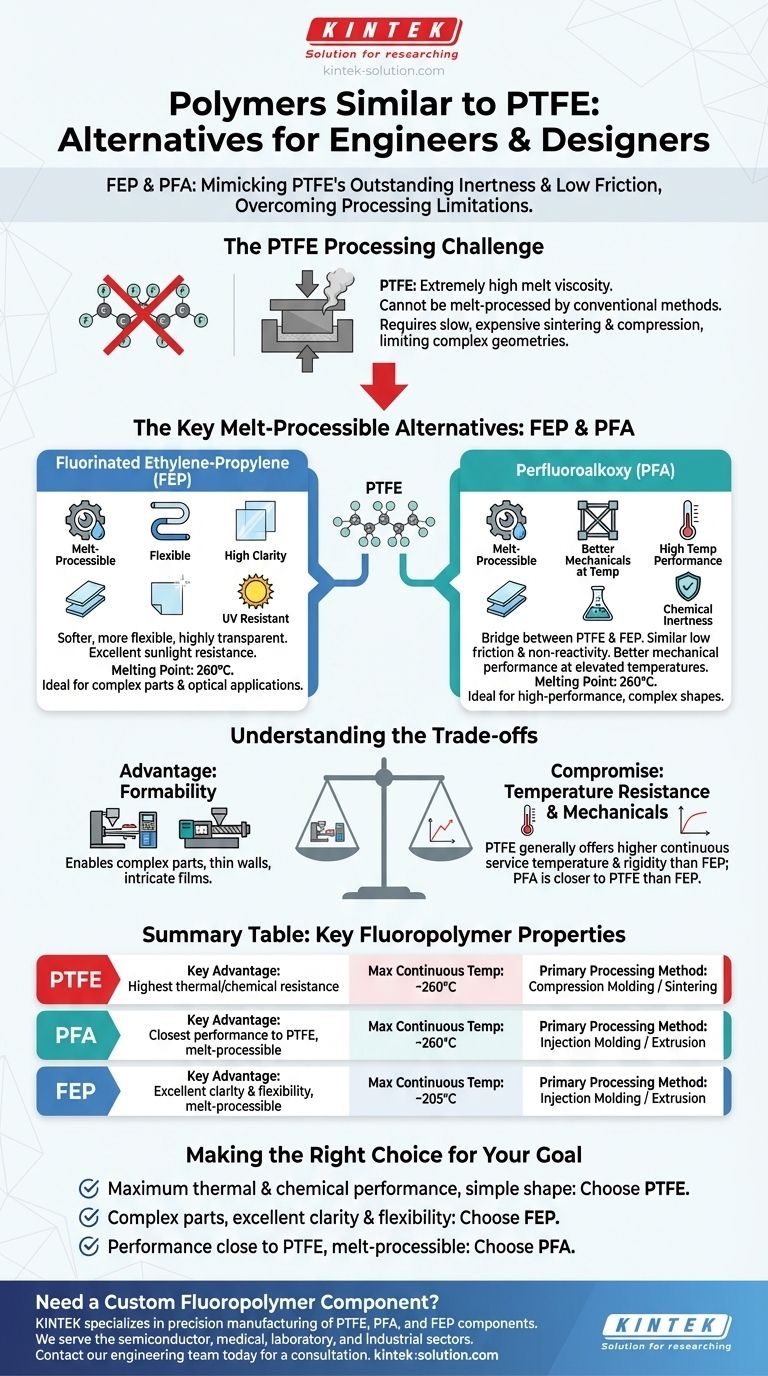

For engineers and designers seeking alternatives to PTFE, the most common and compositionally similar polymers are Fluorinated Ethylene-Propylene (FEP) and Perfluoroalkoxy Polymer Resin (PFA). These materials were specifically developed to mimic PTFE's outstanding chemical inertness and low-friction properties while overcoming its significant processing limitations. They offer a practical solution for creating complex parts that require PTFE-like performance.

The core challenge with PTFE is its inability to be melt-processed, making it difficult to form into intricate shapes. FEP and PFA solve this problem by providing similar fluoropolymer benefits in a package that can be used in conventional manufacturing methods like injection molding and extrusion.

Why Look for Alternatives to PTFE?

Polytetrafluoroethylene (PTFE) is a remarkable material known for its extreme non-reactivity and one of the lowest coefficients of friction of any solid. However, its greatest strength is also linked to its most significant weakness.

The Processing Challenge of PTFE

PTFE has an exceptionally high melt viscosity, meaning even when heated, it does not flow like a typical thermoplastic. This prevents it from being processed using common, high-volume methods like injection molding or melt extrusion.

Instead, PTFE parts must be manufactured through a sintering process similar to powdered metallurgy, which involves compression and baking. This method is often slower, more expensive, and less suitable for producing complex geometries.

The Key Melt-Processible Alternatives

FEP and PFA are both "copolymers" of PTFE, meaning they share its fundamental chemical backbone but include a different monomer to modify their properties. This modification is precisely what allows them to be melt-processed.

Fluorinated Ethylene-Propylene (FEP)

FEP is an excellent alternative when manufacturability and optical clarity are key requirements. It retains the core benefits of a fluoropolymer in a much more versatile form.

Its key characteristics include being softer than PTFE, with a melting point of 260°C. It is also highly transparent and possesses excellent resistance to degradation from sunlight.

Perfluoroalkoxy (PFA)

PFA is often considered the bridge between PTFE and FEP. It was engineered to have properties closer to PTFE, particularly in terms of high-temperature performance, while still being easily formable.

Like FEP, it retains the characteristic low friction and non-reactivity of PTFE but can be easily processed. It generally offers better mechanical performance at elevated temperatures than FEP.

Understanding the Trade-offs

Choosing between PTFE, FEP, and PFA requires a clear understanding of the trade-offs between ultimate performance and processability.

The Advantage: Formability

The single greatest advantage of FEP and PFA is their ability to be melt-processed. This opens the door to creating complex parts, thin-wall tubing, and intricate films that would be difficult or impossible to make with PTFE.

The Compromise: Temperature Resistance

While FEP and PFA have excellent heat resistance, PTFE generally has a higher continuous service temperature. FEP, with its 260°C melting point, cannot match the upper thermal limits of PTFE. PFA closes this gap considerably but typically still falls slightly short of pure PTFE.

The Difference: Mechanical Properties

The application's physical demands are critical. FEP is softer and more flexible than PTFE, which can be an advantage for applications like flexible tubing or wire insulation. PFA offers mechanical properties much closer to PTFE, providing more rigidity and creep resistance than FEP.

Making the Right Choice for Your Goal

Your specific application requirements will dictate which of these fluoropolymers is the correct choice.

- If your primary focus is maximum thermal and chemical performance for a simple shape: PTFE remains the benchmark material.

- If your primary focus is creating complex parts with excellent clarity and flexibility: FEP provides PTFE-like benefits with far superior processability.

- If your primary focus is achieving performance close to PTFE in a melt-processible form: PFA offers a high-performance balance between PTFE's capabilities and FEP's ease of manufacturing.

Ultimately, understanding these alternatives empowers you to select the right material that balances performance, manufacturability, and cost for your specific project.

Summary Table:

| Polymer | Key Advantage | Max Continuous Temp | Primary Processing Method |

|---|---|---|---|

| PTFE | Highest thermal/chemical resistance | ~260°C | Compression Molding / Sintering |

| PFA | Closest performance to PTFE, melt-processible | ~260°C | Injection Molding / Extrusion |

| FEP | Excellent clarity & flexibility, melt-processible | ~205°C | Injection Molding / Extrusion |

Need a Custom Fluoropolymer Component?

Choosing the right material is critical for your application's success. KINTEK specializes in the precision manufacturing of PTFE, PFA, and FEP components—from complex seals and liners to custom labware.

We serve the semiconductor, medical, laboratory, and industrial sectors, offering custom fabrication from prototypes to high-volume production. Our expertise ensures you get the optimal balance of material performance and manufacturability for your project.

Contact our engineering team today for a consultation on your specific requirements.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Evaporating Dishes for Diverse Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the benefits of using PTFE seals? Unmatched Chemical & Temperature Resistance

- What are the key advantages of PTFE rotary seals over traditional rubber seals? Superior Performance in Extreme Conditions

- What are the two temperature extremes discussed for PTFE seals? Maximize Performance from Cryogenic to High-Heat

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- What are some common PTFE seal types used in industrial applications? Explore Solutions for Every Motion & Environment