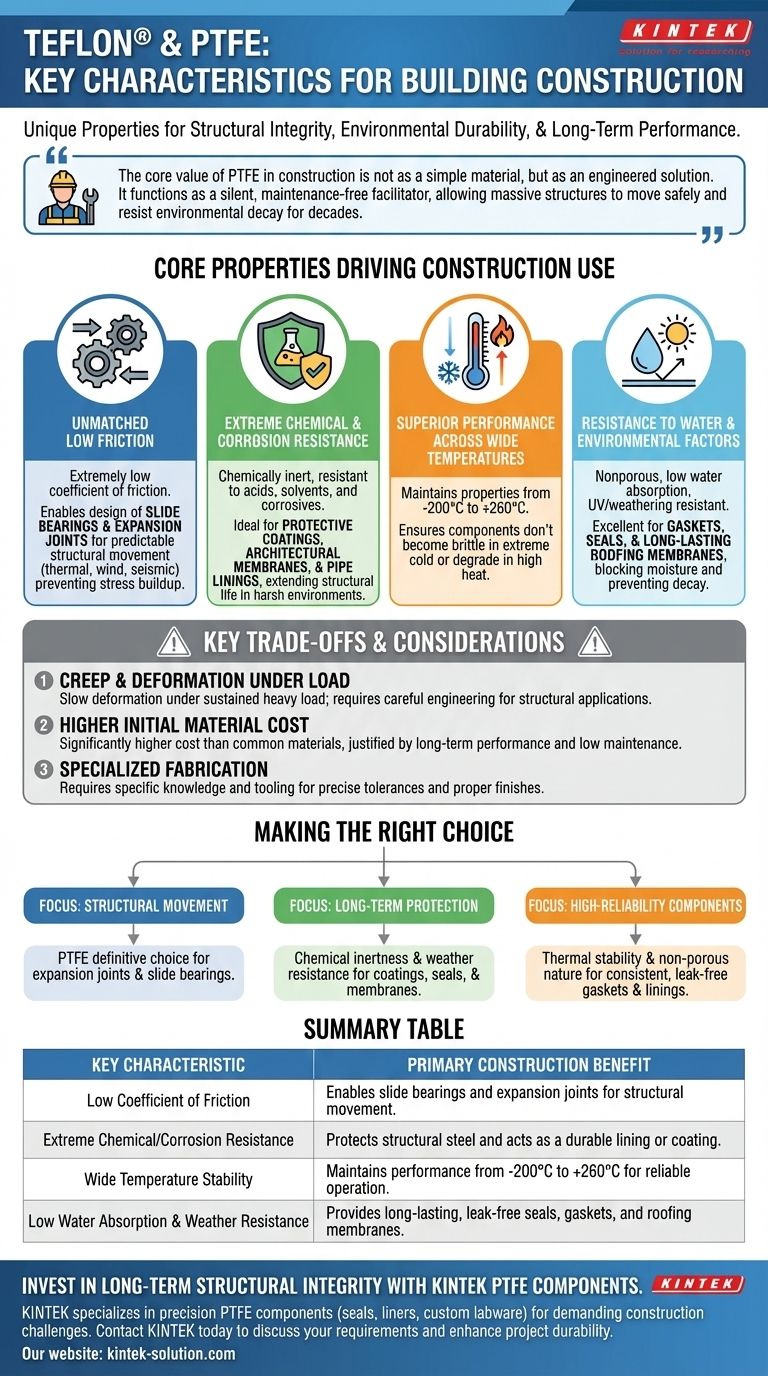

In building construction, Teflon and PTFE are specified for their unique combination of properties. Chief among these are an extremely low coefficient of friction, exceptional chemical and corrosion resistance, and stability across a wide range of temperatures. These characteristics allow PTFE to solve critical engineering challenges related to structural movement, environmental durability, and long-term material integrity where conventional materials would fail.

The core value of PTFE in construction is not as a simple material, but as an engineered solution. It functions as a silent, maintenance-free facilitator, allowing massive structures to move safely and resist environmental decay for decades.

The Core Properties Driving Construction Use

Polytetrafluoroethylene (PTFE), commonly known by the brand name Teflon, possesses a set of physical and chemical properties that make it uniquely suited for demanding architectural and engineering applications.

Unmatched Low Friction

PTFE has one of the lowest coefficients of friction of any known solid material. This "slipperiness" is its most famous characteristic.

In construction, this allows for the design of slide bearings and expansion joints. These components permit large structural elements—like bridge decks, stadium roofs, or even entire buildings—to move predictably in response to thermal expansion, wind loads, or seismic activity, preventing the buildup of destructive stress.

Extreme Chemical and Corrosion Resistance

PTFE is almost completely chemically inert. It is highly resistant to nearly all acids, solvents, and corrosive agents.

This makes it an ideal material for protective coatings, architectural membranes, and pipe linings. In harsh industrial or coastal environments, a PTFE coating can protect structural steel from rust and chemical attack, dramatically extending its service life.

Superior Performance Across Wide Temperatures

PTFE maintains its key properties over an exceptionally broad temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This thermal stability ensures that components made from PTFE will not become brittle in extreme cold or degrade in high heat. This reliability is essential for materials used in building envelopes and structures exposed to diverse and fluctuating climates.

Resistance to Water and Environmental Factors

The material is nonporous and exhibits extremely low water absorption. It is also highly resistant to UV radiation and weathering.

These attributes make it an excellent choice for gaskets, seals, and long-lasting roofing membranes. It effectively blocks moisture ingress, preventing leaks and protecting the building's internal structure from water damage and decay over time.

Key Trade-offs and Considerations

While its properties are exceptional, PTFE is a specialized material whose application requires careful engineering consideration.

Creep and Deformation Under Load

Despite good dimensional stability for a polymer, PTFE can be subject to "creep"—a slow deformation under a sustained, heavy load.

Structural applications, such as slide bearings, must be carefully designed to manage compressive loads and ensure the material does not deform beyond acceptable limits over the building's lifespan.

Higher Initial Material Cost

PTFE is a high-performance fluoropolymer, and its cost is significantly higher than that of more common construction materials like steel, concrete, or neoprene.

Its use is therefore justified in applications where long-term performance, low maintenance, and high reliability are critical priorities that outweigh the initial investment.

Specialized Fabrication

While the material has excellent machinability, fabricating components from PTFE requires specific knowledge and tooling compared to working with traditional metals.

Achieving precise tolerances and proper finishes is essential for performance, especially in components like seals and bearings, requiring experienced fabricators.

Making the Right Choice for Your Goal

Selecting PTFE is a strategic decision based on solving a specific, high-stakes problem.

- If your primary focus is managing structural movement: PTFE's unparalleled low-friction properties make it the definitive choice for expansion joints and structural slide bearings.

- If your primary focus is long-term environmental protection: Its chemical inertness and weather resistance provide maximum durability for coatings, seals, and membranes in corrosive or exposed locations.

- If your primary focus is high-reliability components: Its thermal stability and non-porous nature ensure consistent, leak-free performance for critical gaskets and linings in plumbing and HVAC systems.

Ultimately, leveraging PTFE in construction is an investment in long-term resilience, minimizing future maintenance and maximizing the safety and integrity of the structure.

Summary Table:

| Key Characteristic | Primary Construction Benefit |

|---|---|

| Low Coefficient of Friction | Enables slide bearings and expansion joints for structural movement. |

| Extreme Chemical/Corrosion Resistance | Protects structural steel and acts as a durable lining or coating. |

| Wide Temperature Stability | Maintains performance from -200°C to +260°C for reliable operation. |

| Low Water Absorption & Weather Resistance | Provides long-lasting, leak-free seals, gaskets, and roofing membranes. |

Invest in Long-Term Structural Integrity with KINTEK PTFE Components

Are you designing a project that requires reliable movement, superior environmental protection, or high-performance seals? The unique properties of PTFE—low friction, chemical inertness, and thermal stability—are engineered to solve these exact challenges in demanding construction applications.

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring your project benefits from material excellence and expert craftsmanship.

Let's build a more resilient future together. Contact KINTEK today to discuss your specific requirements and how our PTFE solutions can enhance your project's durability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability