Simply put, PTFE valve seat rings are used in industries where process purity, chemical resistance, and operational reliability are non-negotiable. Their primary applications are within process valves for the chemical, pharmaceutical, bioprocessing, and agricultural industries due to their unique material properties.

The selection of PTFE for a valve seat is less about the industry and more about the environment. It is the default choice for applications involving corrosive chemicals, high-purity media, or where low-friction, reliable sealing is paramount.

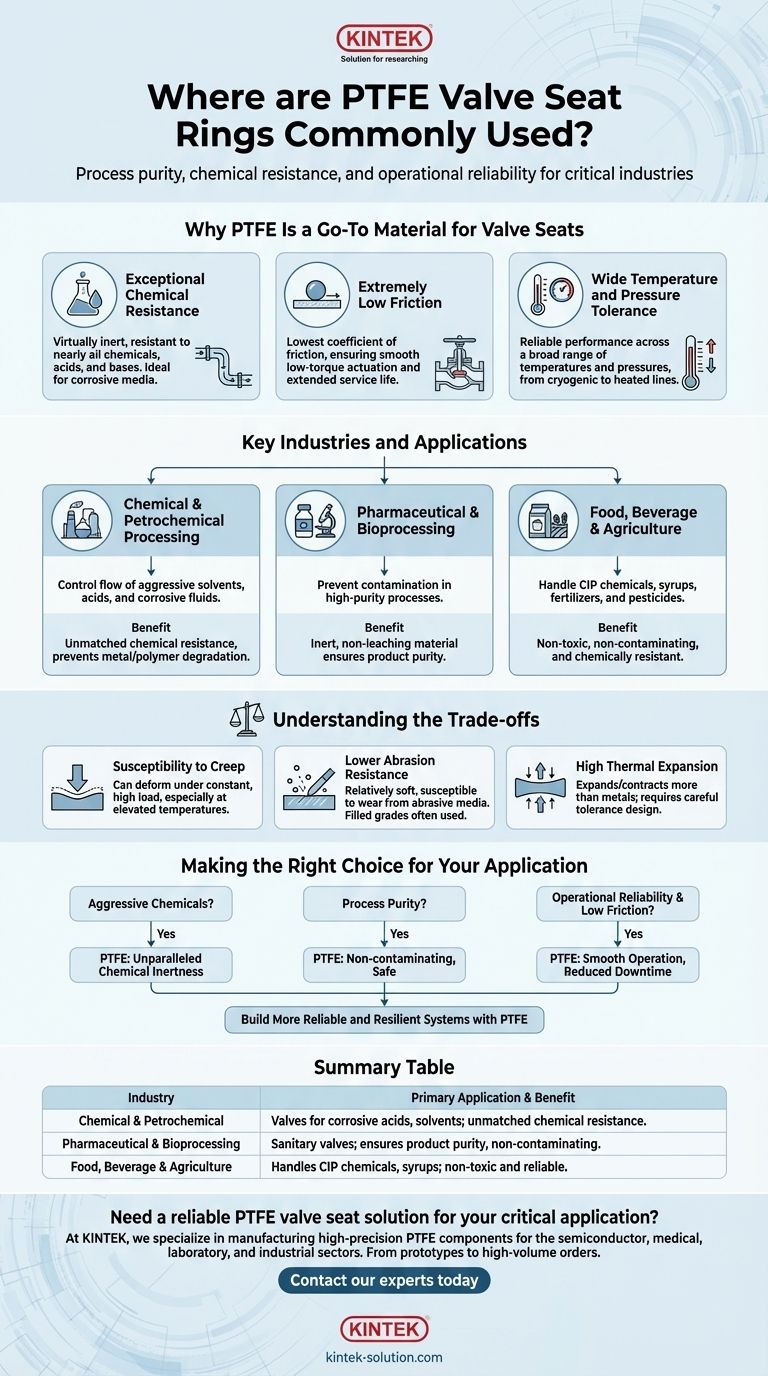

Why PTFE Is a Go-To Material for Valve Seats

The reason PTFE is so prevalent in demanding valve applications comes down to three core material characteristics. These properties solve critical engineering challenges that other materials cannot easily address.

### Exceptional Chemical Resistance

PTFE is virtually inert and resistant to almost all industrial chemicals, acids, and bases. This makes it an ideal sealing material for equipment that will handle corrosive or reactive media.

This property is the primary reason for its heavy use in chemical processing and transport systems.

### Extremely Low Friction

Known for its non-stick surface, PTFE has one of the lowest coefficients of friction of any solid material.

In a valve, this ensures smooth, low-torque actuation and prevents the valve components from seizing, which significantly improves operational reliability and service life.

### Wide Temperature and Pressure Tolerance

PTFE valve seats can perform reliably across a broad range of temperatures and pressures.

This versatility allows them to be specified for everything from cryogenic services to heated process lines, providing a consistent sealing solution for various industrial applications.

Key Industries and Applications

While PTFE's properties make it broadly useful, it has become a standard component in several specific sectors where performance and safety cannot be compromised.

### Chemical and Petrochemical Processing

This is the most common application area. PTFE seats are used in ball valves, butterfly valves, and plug valves that control the flow of aggressive solvents, acids, and other corrosive fluids that would degrade metal or other polymer seals.

### Pharmaceutical and Bioprocessing

In these high-purity industries, preventing contamination of the process media is critical.

Because PTFE is inert and does not leach substances, it ensures that products like pharmaceuticals and fine chemicals remain pure and unadulterated.

### Food, Beverage, and Agriculture

Similar to pharmaceuticals, the food and beverage industry relies on PTFE for its non-toxic and non-contaminating properties.

It is frequently used in sanitary valves and for handling various liquids, syrups, and clean-in-place (CIP) chemicals. In agriculture, its chemical resistance is valued for handling fertilizers and pesticides.

Understanding the Trade-offs

No material is perfect. While PTFE offers significant advantages, an objective evaluation requires acknowledging its limitations in certain contexts.

### Susceptibility to Creep

Under a constant, high mechanical load—especially at elevated temperatures—PTFE can slowly deform over time. This phenomenon, known as "creep," must be accounted for in the valve's design to ensure a long-lasting seal.

### Lower Abrasion Resistance

Compared to harder materials, pure PTFE is relatively soft and can be susceptible to wear from abrasive particles or slurries in the process media. In such cases, filled grades of PTFE are often used to enhance durability.

### High Thermal Expansion

PTFE expands and contracts more than metals with changes in temperature. Engineers must design the valve and seat with appropriate tolerances to maintain seal integrity across the entire operational temperature range.

Making the Right Choice for Your Application

Selecting the right valve seat material is about matching the material's properties to the demands of your specific process environment.

- If your primary focus is handling aggressive chemicals: PTFE is almost certainly the correct choice due to its unparalleled chemical inertness.

- If your primary focus is process purity: For pharmaceutical, food, or semiconductor applications, PTFE's non-contaminating nature makes it a safe and reliable option.

- If your primary focus is operational reliability and low friction: PTFE's low-friction surface ensures smooth valve operation and helps prevent costly downtime.

Ultimately, understanding the unique strengths and limitations of PTFE empowers you to build more reliable and resilient systems.

Summary Table:

| Industry | Primary Application & Benefit |

|---|---|

| Chemical & Petrochemical | Valves for corrosive acids, solvents; unmatched chemical resistance. |

| Pharmaceutical & Bioprocessing | Sanitary valves; ensures product purity, non-contaminating. |

| Food, Beverage & Agriculture | Handles CIP chemicals, syrups; non-toxic and reliable. |

Need a reliable PTFE valve seat solution for your critical application?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom valve seat rings, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your valves deliver the chemical resistance, purity, and operational reliability your process demands—from prototypes to high-volume orders.

Contact our experts today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the advantages and disadvantages of PTFE Lined Ball Valves? Specialized Corrosion Control for Your Process

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does the coefficient of friction behave in PTFE sliding pipe supports? Ensure Predictable, Low-Friction Movement

- How does PTFE's low thermal conductivity impact machining? Master Heat Management for Precision Parts

- What types of applications commonly use PTFE rotary seals? Solve Extreme Chemical, Temperature, and Speed Challenges

- What are the key properties of PTFE industrial coating? Discover Unmatched Performance for Demanding Industries

- What factors influence the selection of PTFE compounds for piston rings? Match Your Application's Demands

- What role do PTFE gaskets play in the energy and power industry? Ensuring Safety and Reliability in Critical Infrastructure