In short, PTFE rotary seals are used in demanding applications where standard elastomer seals would fail due to aggressive chemicals, extreme temperatures, or high speeds and pressures. They are critical components across a vast range of industries, including aerospace, oil and gas, chemical processing, pharmaceutical manufacturing, and heavy industrial machinery.

The decision to use a PTFE rotary seal is not driven by the industry itself, but by the operational challenge. These seals are chosen when conditions are too harsh for conventional materials, making them a solution for engineering problems involving chemical attack, extreme heat or cold, and high-velocity motion.

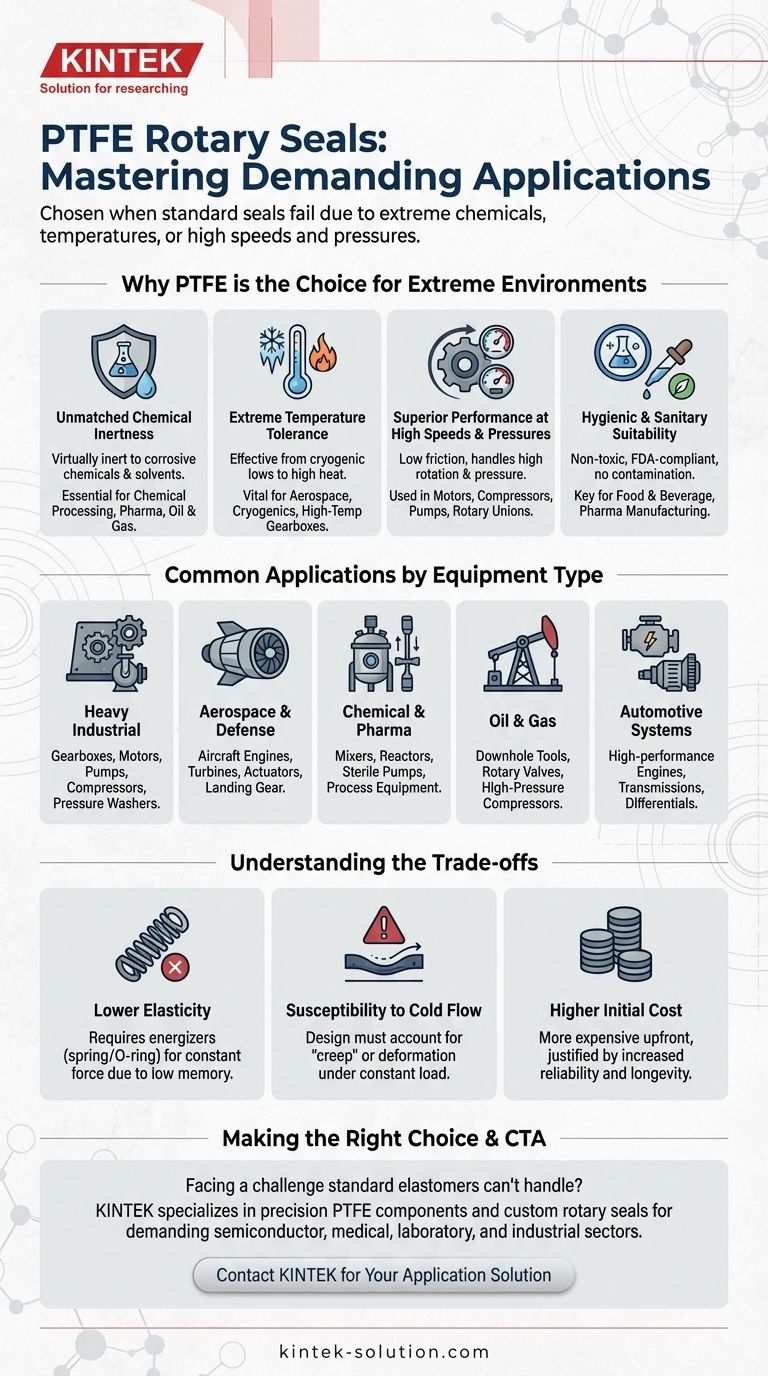

Why PTFE is the Material of Choice for Demanding Applications

The unique properties of Polytetrafluoroethylene (PTFE) make it an indispensable material for sealing in extreme environments. Understanding these properties explains its widespread adoption in critical systems.

Unmatched Chemical Inertness

PTFE is virtually inert and resistant to almost all industrial chemicals and solvents. This makes it the default choice for equipment that handles corrosive or aggressive media.

This property is essential in the chemical processing, pharmaceutical, and oil and gas industries, where seals are constantly exposed to harsh substances.

Extreme Temperature Tolerance

PTFE seals can function effectively across an exceptionally wide temperature range, from cryogenic lows to high-heat conditions where traditional rubber seals would become brittle or degrade.

This makes them vital for aerospace applications like aircraft engines and turbines, as well as for industrial equipment such as cryogenic systems and high-temperature gearboxes.

Superior Performance at High Speeds and Pressures

PTFE has an extremely low coefficient of friction, allowing it to handle high rotational speeds with minimal heat generation and wear. Its robust structure also maintains integrity under high pressure.

This is why PTFE seals are commonly found in high-performance motors, compressors, pumps, and rotary unions.

Suitability for Hygienic and Sanitary Environments

Because PTFE is non-toxic and chemically stable, it can be manufactured to meet stringent regulatory standards, including those from the FDA. It does not contaminate the media it contacts.

This characteristic is non-negotiable in food and beverage processing and pharmaceutical manufacturing for equipment like mixers, pumps, and filling machines.

A Breakdown of Common Applications by Equipment Type

While many industries benefit from PTFE seals, it's often more practical to look at the specific types of machinery where they are deployed.

Heavy Industrial Machinery

This category includes a wide array of equipment where reliability is paramount. Key applications include gearboxes, motors, pumps, compressors, and industrial pressure washers.

Aerospace and Defense Systems

In this sector, performance under extreme conditions is a matter of safety. PTFE seals are used in aircraft engines, turbines, actuators, and landing gear systems.

Chemical and Pharmaceutical Processing

To ensure product purity and operational safety, these seals are critical. You will find them in mixers, reactors, pumps, and other sterile process equipment.

Oil and Gas Equipment

From extraction to refining, equipment must withstand harsh environments. Common uses include downhole tools, rotary valves, and high-pressure compressors.

Automotive Systems

Modern vehicles rely on efficient, long-lasting components. PTFE seals are integral to high-performance engines, transmissions, and differentials.

Understanding the Trade-offs

While highly effective, PTFE seals are not a universal solution. An objective assessment requires understanding their limitations.

Lower Elasticity

Unlike rubber, PTFE is not a true elastomer and has very little "memory." It will not spring back to its original shape after being compressed.

For this reason, PTFE seals almost always incorporate an energizer, such as a metal spring or an O-ring, to provide the constant force needed to maintain a reliable seal.

Susceptibility to Cold Flow

Under a constant load, PTFE can slowly deform over time, a phenomenon known as "creep" or "cold flow." This must be accounted for in the seal and hardware design to ensure long-term performance.

Higher Initial Cost

Generally, high-performance PTFE seal assemblies are more expensive than standard elastomeric lip seals. However, this higher upfront cost is often justified by increased reliability, longer service life, and reduced downtime in critical applications.

Making the Right Choice for Your Application

Selecting the correct seal depends entirely on the specific challenges of your operating environment.

- If your primary focus is resisting aggressive chemicals: PTFE's inertness makes it a superior choice for chemical reactors, pumps, and valves.

- If your primary focus is operating at extreme temperatures: PTFE's stability in both cryogenic and high-heat conditions is essential for aerospace and specialized industrial equipment.

- If your primary focus is handling high rotational speeds or pressures: The low-friction and high-strength properties of PTFE are ideal for performance motors, compressors, and gearboxes.

- If your primary focus is meeting strict sanitary standards: PTFE's purity and compliance make it the go-to material for food, beverage, and pharmaceutical processing.

Ultimately, choosing a PTFE rotary seal is a strategic decision to ensure operational integrity where other materials would fail.

Summary Table:

| Application Area | Common Equipment | Key PTFE Property Utilized |

|---|---|---|

| Heavy Industrial Machinery | Gearboxes, Pumps, Compressors | High-speed, low-friction performance |

| Aerospace & Defense | Aircraft Engines, Turbines, Actuators | Extreme temperature tolerance |

| Chemical & Pharmaceutical Processing | Mixers, Reactors, Sterile Pumps | Unmatched chemical inertness |

| Oil & Gas Equipment | Downhole Tools, Compressors, Valves | Resistance to harsh chemicals and high pressure |

| Automotive Systems | High-performance Engines, Transmissions | Durability and low friction at high speeds |

Facing a sealing challenge that standard elastomers can't handle? KINTEK specializes in precision PTFE components, including custom rotary seals for the most demanding environments in semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a reliable, high-performance seal designed for your specific operational needs.

Contact KINTEK today to discuss your application and receive a solution that guarantees integrity under extreme conditions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments