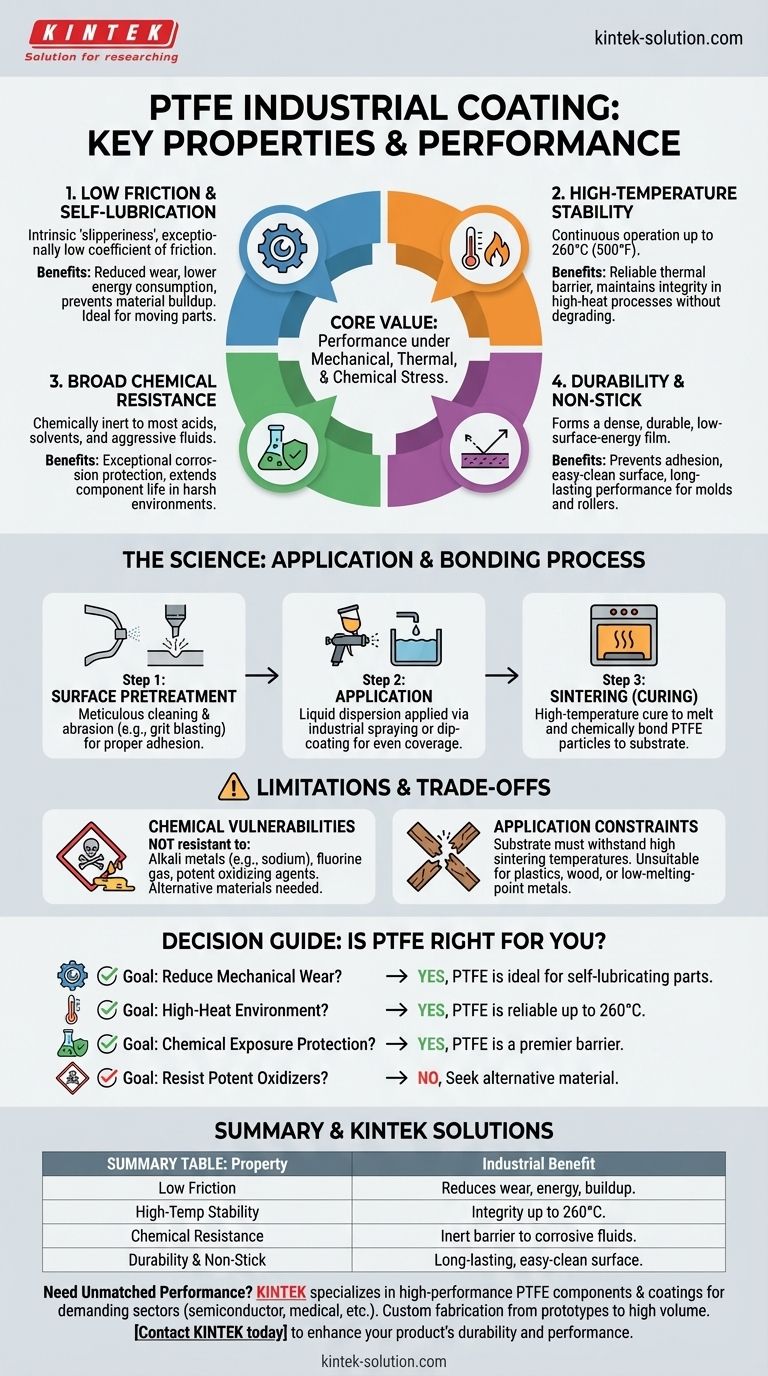

At its core, PTFE industrial coating is defined by a unique combination of four key properties. These are an exceptionally low coefficient of friction (making it one of the most slippery materials known), high-temperature resistance, broad chemical inertness, and excellent durability. This synergy makes it a highly versatile solution for demanding industrial environments.

While often recognized for the "non-stick" surface it creates, the true industrial value of PTFE lies in its ability to maintain high performance under a triad of stresses: mechanical (friction), thermal (heat), and chemical. Understanding its application process and specific chemical limitations is the key to leveraging its full potential.

Deconstructing the Core Properties of PTFE

Polytetrafluoroethylene (PTFE) is a fluoropolymer with a unique molecular structure that gives rise to its valuable industrial characteristics. Each property addresses a distinct set of operational challenges.

Unmatched Low Friction and Self-Lubrication

PTFE possesses one of the lowest coefficients of friction of any solid material. This "slipperiness" is not just a surface-level effect; it is an intrinsic property.

In industrial applications, this translates directly to reduced wear and tear on moving parts, lower energy consumption, and the prevention of material buildup. This self-lubricating nature makes it ideal for components where traditional liquid lubricants are impractical.

High-Temperature Stability

PTFE coatings maintain their integrity and performance at continuous operating temperatures up to 260°C (500°F).

This allows it to be used in high-heat processes and machinery without degrading, melting, or losing its essential properties. It provides a reliable thermal barrier for components subjected to harsh temperature cycles.

Broad Chemical and Corrosion Resistance

PTFE is chemically inert and does not react with the vast majority of industrial chemicals, solvents, acids, and aggressive fluids.

This property makes it an exceptional corrosion-resistant barrier. It protects the underlying substrate from degradation, extending the life of parts used in chemical processing, fluid handling, and other corrosive environments.

Durability and Non-Stick Performance

When properly applied, a PTFE coating forms a dense, durable, and long-lasting film. Its non-stick nature is a direct result of its low surface energy.

This prevents other materials from adhering to the surface, which is critical for applications ranging from food processing equipment to molds and industrial rollers.

The Science Behind the Coating: Application and Bonding

A PTFE coating's performance is not just a function of the material itself, but also of how it is applied. The process is designed to create a permanent, high-integrity bond with the substrate.

The Critical Role of Surface Pretreatment

The substrate surface must be meticulously cleaned and often mechanically abraded (e.g., grit blasting) before coating. This crucial first step ensures the PTFE has a proper surface to adhere to.

Application via Spraying or Dip-Coating

A liquid dispersion of PTFE particles is applied to the prepared part. This is typically done through industrial spraying or a dip-coating process to ensure even and complete coverage.

Sintering: Fusing the Coating to the Substrate

After application, the part is cured at high temperatures in a process called sintering. This melts the PTFE particles, causing them to flow together and bond chemically to the substrate. The result is a smooth, non-porous, and continuous film.

Understanding the Trade-offs and Limitations

No material is perfect for every scenario. Acknowledging PTFE's limitations is essential for correct specification and avoiding application failure.

Chemical Vulnerabilities

While highly resistant, PTFE is not invincible. It can be attacked by a few specific and highly reactive substances.

PTFE is not resistant to liquid or dissolved alkali metals (like sodium), fluorine gas, and other extremely potent oxidizing agents. In these specific environments, an alternative material must be chosen.

Application Process Constraints

The need for high-temperature curing is a significant constraint. The substrate material must be able to withstand the sintering temperatures without warping or being damaged.

This means PTFE coating is generally unsuitable for plastics, wood, or low-melting-point metals. The requirement for thorough surface preparation also adds a step of complexity and cost to the manufacturing process.

How to Determine if PTFE is Right for Your Application

Use the following criteria to make a clear decision based on your primary operational goal.

- If your primary focus is reducing mechanical wear and friction: PTFE's exceptionally low coefficient of friction makes it ideal for self-lubricating parts, bearings, and surfaces where you need to minimize energy loss.

- If your primary focus is performance in high-heat environments: Its stability up to 260°C (500°F) ensures reliability where many other polymer coatings would degrade or fail.

- If your primary focus is protecting against chemical exposure: PTFE provides an inert barrier against a vast range of acids, solvents, and corrosive fluids, making it a premier choice for chemical processing equipment.

- If your application involves potent oxidizers or alkali metals: You must seek an alternative material, as PTFE is not resistant to these specific, highly reactive chemical agents.

By understanding both its powerful benefits and its specific limitations, you can confidently specify PTFE coating for applications where it will deliver maximum performance and reliability.

Summary Table:

| Key Property | Industrial Benefit |

|---|---|

| Low Coefficient of Friction | Reduces wear, lowers energy consumption, prevents material buildup. |

| High-Temperature Stability (up to 260°C/500°F) | Maintains integrity in high-heat processes without degrading. |

| Broad Chemical & Corrosion Resistance | Provides an inert barrier against most acids, solvents, and aggressive fluids. |

| Durability & Non-Stick Performance | Creates a long-lasting, easy-clean surface that prevents adhesion. |

Need a PTFE coating solution that delivers unmatched performance?

At KINTEK, we specialize in high-performance PTFE components and coatings tailored for the most demanding environments in the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your parts benefit from superior friction reduction, thermal stability, and chemical resistance.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision to meet your exact specifications.

Contact KINTEK today to discuss how our PTFE solutions can enhance your product's durability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the advantages of glass fiber filled PTFE? Boost Strength & Resist Wear

- What are PTFE Teflon washers? The Ultimate Guide to High-Performance Sealing

- What is the shape and material of the PTFE Lined Spacer? A Guide to Its Round Design and PTFE Benefits

- What are the pros and cons of PTFE Lined Gate Valves? Unlock Reliable Corrosion Control

- What are some common applications of PTFE coatings? Explore Their Versatile Uses

- What are some common applications of machined Teflon? Critical Components for Harsh Environments

- What are the limitations of virgin PTFE for rotary shaft seals? Overcome Weakness with Filled Compounds

- What temperature range can welded PTFE bellow seals withstand? Unmatched Performance from -200°C to +260°C