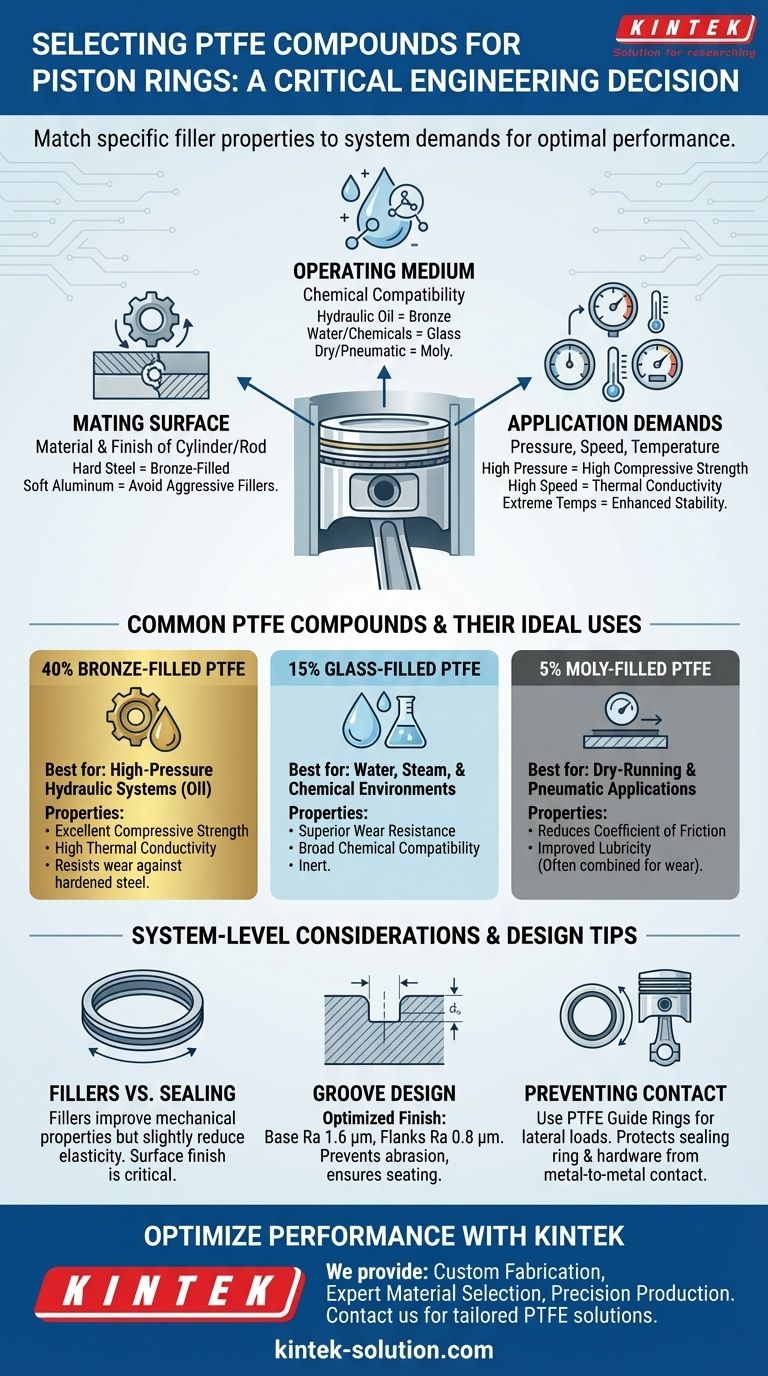

The selection of a PTFE compound for piston rings is a critical engineering decision driven by the specific environment in which the ring will operate. Your choice is primarily dictated by the mating contact surface material, the chemical nature of the operating medium (e.g., hydraulic fluid, water, or air), and the application's performance demands, such as pressure, temperature, and piston speed.

Choosing the right PTFE compound is not about finding the single "best" material, but about matching a specific filler's properties—like wear resistance, thermal conductivity, or chemical inertness—to the precise mechanical and chemical demands of your system.

Deconstructing the Core Selection Factors

To choose the optimal compound, you must analyze how the material will interact with its environment. Each factor places a different stress on the piston ring, and the right filler is chosen to counteract that specific stress.

The Mating Surface

The material and finish of the cylinder bore or piston rod are critical. A hard mating surface, like hardened steel, can accommodate an aggressive, wear-resistant filler like bronze. Using such a compound against a softer surface, like aluminum, could cause premature wear of the cylinder itself.

The Operating Medium

The fluid or gas being sealed is the next consideration. The filler material must be chemically compatible with the medium. An incorrect match can lead to material degradation and seal failure.

For example, bronze fillers are excellent for oil-based hydraulic systems but can oxidize in the presence of water or certain chemicals. Glass fillers, conversely, are highly inert and perform exceptionally well in water and chemically aggressive environments.

Application Demands: Pressure, Speed, and Temperature

The operational parameters determine the mechanical and thermal loads on the ring.

- Pressure: High pressure requires a compound with high compressive strength and resistance to extrusion.

- Speed: High piston speeds generate more frictional heat. A compound with high thermal conductivity is needed to dissipate this heat and prevent failure.

- Temperature: While PTFE has a wide operating range (typically –60 °C to +200 °C), fillers can enhance its stability and wear properties at the extremes of this range.

A Look at Common PTFE Compounds

While countless custom blends exist, a few common compounds cover the majority of applications. Understanding their properties reveals the logic behind their selection.

40% Bronze-Filled PTFE

This is a very common choice for hydraulic systems. The bronze filler provides excellent compressive strength to resist high pressures and high thermal conductivity to manage heat generated at high speeds. It is best suited for systems using hydraulic oil and operating against hardened steel surfaces.

15% Glass-Filled PTFE

Glass fibers significantly increase wear resistance and offer broad chemical compatibility. This makes glass-filled PTFE a versatile choice, particularly effective in applications involving water, steam, or other chemicals where a bronze filler would corrode.

5% Molybdenum Disulfide (Moly) Filled PTFE

Molybdenum disulfide is primarily added to reduce the coefficient of friction. It creates a smoother, lower-friction seal, but typically does not increase wear resistance as much as glass or bronze. It is often combined with other fillers to improve lubricity.

Understanding the Trade-offs and System-Level Factors

Selecting a compound is only part of the solution. A perfectly chosen material will fail if the surrounding system design is flawed.

Fillers vs. Sealing Ability

Adding fillers improves mechanical properties like wear resistance and compressive strength. However, it also makes the PTFE less elastic than its virgin state. This can slightly impact the ring's ability to conform to imperfections, making factors like surface finish even more critical.

The Importance of Groove Design

The piston groove that houses the ring must be manufactured correctly. For optimal performance, the groove base should have a surface roughness around Ra 1.6 µm, while the flanks require a smoother finish of Ra 0.8 µm. A rough finish will abrade the ring, and a finish that is too smooth can inhibit proper seating.

Preventing Metal-to-Metal Contact

The primary role of a PTFE piston ring is to seal. It is not designed to support lateral loads. In applications where side-loading can occur, PTFE guide rings are used to prevent metal-to-metal contact between the piston and the cylinder, protecting both the sealing ring and the hardware from damage.

Making the Right Choice for Your Application

Use your specific operating conditions as a clear guide to the best material choice.

- If your primary focus is a high-pressure hydraulic oil system: Bronze-filled PTFE is likely the optimal choice due to its high compressive strength and thermal conductivity.

- If your primary focus is chemical compatibility or water-based systems: Glass-filled PTFE offers superior wear resistance and inertness for these environments.

- If your primary focus is minimizing friction in a dry-running or pneumatic application: A carbon/graphite or Moly-filled compound can provide the necessary lubricity.

- If you are designing a complete piston assembly: Remember to incorporate guide rings to manage side loads and specify the correct groove surface finish to maximize the life of your chosen piston ring.

Ultimately, a successful design hinges on precisely matching the properties of the PTFE filler to the unique mechanical, thermal, and chemical demands of your application.

Summary Table:

| Selection Factor | Key Consideration | Common PTFE Compound Match |

|---|---|---|

| Mating Surface | Hardness and finish of cylinder/piston rod | Bronze-filled for hardened steel; avoid aggressive fillers on soft metals like aluminum |

| Operating Medium | Chemical compatibility (oil, water, chemicals) | Bronze for oil; Glass for water/chemicals; Moly for low friction in dry/pneumatic |

| Pressure | High compressive strength and extrusion resistance | 40% Bronze-filled PTFE for high-pressure hydraulic systems |

| Speed & Temperature | Thermal conductivity and heat dissipation | Bronze or Glass-filled for high-speed applications to manage frictional heat |

| Chemical Inertness | Resistance to corrosion and degradation | 15% Glass-filled PTFE for aggressive chemical or water-based environments |

Optimize Your Piston Ring Performance with KINTEK

Selecting the right PTFE compound is crucial for the efficiency and longevity of your piston seals. At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We provide:

- Custom Fabrication: From prototypes to high-volume orders, tailored to your specific operating conditions.

- Expert Material Selection: Guidance on the optimal PTFE compound (bronze-filled, glass-filled, moly-filled, and more) for your application's demands.

- Precision Production: Ensuring every component meets exact specifications for superior performance.

Let us help you enhance your system's reliability. Contact us today to discuss your piston ring requirements and get a customized solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does PTFE gland packing differ from other PTFE packing types? Discover the Right Sealing Solution

- What is expanded PTFE (ePTFE) and what makes its structure unique? Unlock Superior Sealing & Performance

- What are the key properties of PTFE for lip seals? Master Sealing in Extreme Conditions

- What are some popular material choices for PTFE piston rings? Enhance Performance with the Right PTFE Compound

- What is the heat-set process for PTFE seal elements? Simplify Installation and Ensure a Reliable Seal

- Why are PTFE O-Rings considered versatile for low-pressure, static applications? Unlock Superior Chemical and Thermal Resistance

- What are the primary industrial applications of PTFE-coated O-rings? Solve Critical Sealing Challenges

- Are Teflon PTFE sheets compatible with all heat press machines? The Essential Guide to Protecting Your Equipment & Projects