In the energy and power sector, PTFE gaskets function as indispensable components for sealing and insulation in critical electrical equipment. They are specified for generators, transformers, and switch cabinets because they provide superior resistance to high temperatures, high pressures, and electrical current, ensuring operational stability and safety.

The fundamental role of a PTFE gasket is to guarantee the integrity and reliability of critical power infrastructure. Its unique combination of electrical insulation, chemical inertness, and physical resilience directly addresses the industry's core demands for safety, efficiency, and minimal downtime.

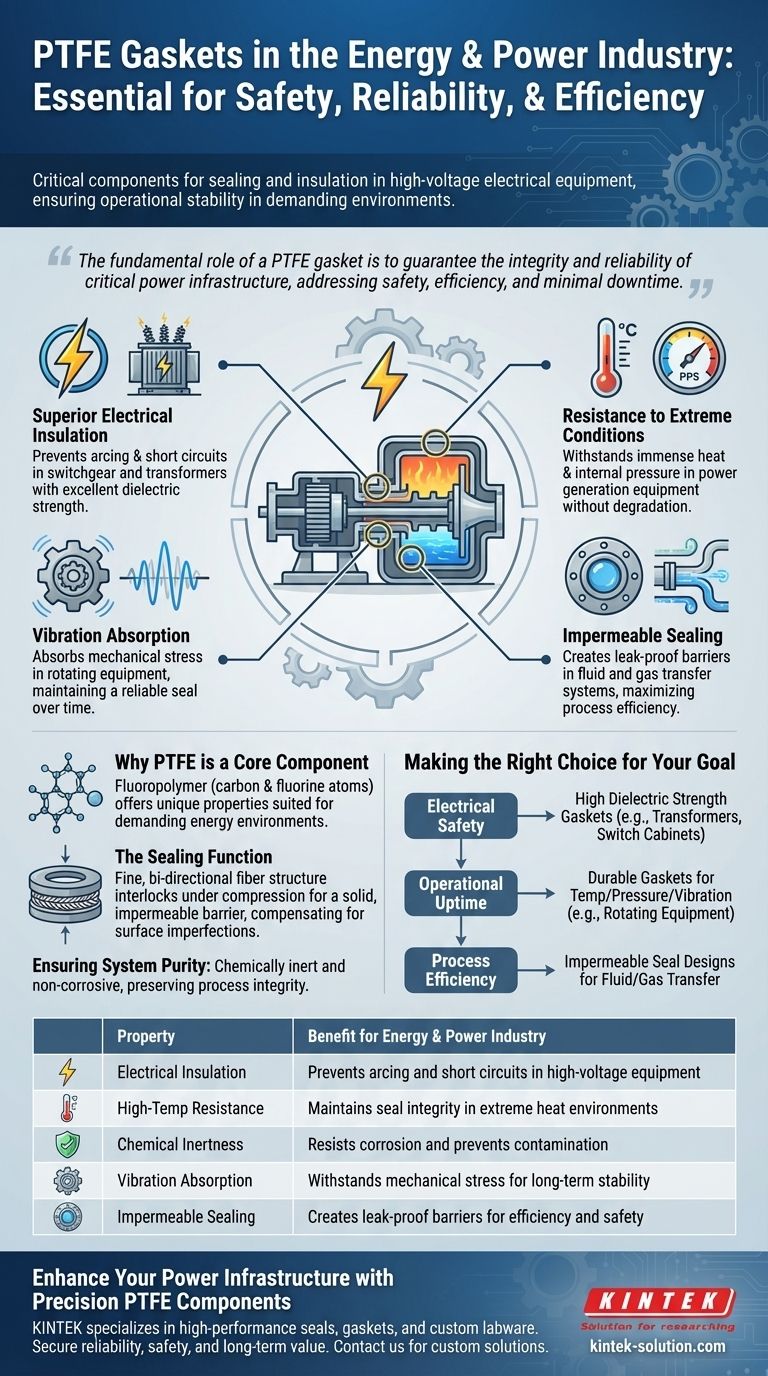

Why PTFE is a Core Component in Power Generation

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer made entirely of carbon and fluorine atoms. This simple, strong structure gives it properties that are uniquely suited for the demanding environments found in the energy industry.

The Need for Superior Electrical Insulation

In high-voltage equipment like switchgear and transformers, preventing electrical arcing or leakage is paramount for safety and function.

PTFE provides excellent electrical insulation, containing the flow of current and preventing costly failures or hazardous short circuits.

Resistance to Extreme Operating Conditions

Power generation equipment operates under immense stress, producing significant heat and internal pressure.

PTFE gaskets are engineered to withstand these high-temperature and high-pressure environments without degrading, ensuring a consistent and reliable seal.

Withstanding Mechanical Stress

Generators and other rotating equipment produce constant vibrations that can compromise weaker materials over time.

The unique structure of PTFE allows it to absorb these stresses, maintaining its seal and contributing to the overall stability of the machinery.

The Sealing Function: Maximizing Efficiency and Safety

Beyond insulation, the primary mechanical function of a gasket is to create a perfect seal between two surfaces. PTFE accomplishes this with remarkable effectiveness.

Creating an Impermeable Barrier

PTFE gaskets possess a fine, bi-directional fiber structure that is highly elastic when uncompressed.

When compressed during installation, these fibers interlock to form a solid and impermeable structure that prevents gas or liquid leaks.

This structure also allows the gasket to compensate for minor surface imperfections on machinery flanges, ensuring a tight seal where other materials might fail.

Application in Rotating and Transfer Equipment

In systems like coupled pumps or liquid and gas transfer lines, preventing leaks is crucial for efficiency and environmental safety.

PTFE's ability to form a watertight and gas-tight seal makes it ideal for these applications, improving the overall efficiency of the process.

Ensuring System Purity

Because PTFE is chemically inert and non-corrosive, it does not react with or contaminate the fluids or gases within a system. This preserves the integrity of the process and the equipment itself.

Key Considerations and Limitations

While PTFE is a highly versatile and durable material, its effectiveness depends entirely on correct specification and application.

The Importance of Correct Specification

PTFE can be mechanically formed into countless shapes, including flat gaskets, V-shaped rings, and custom-cut designs.

Choosing the wrong shape or density for a specific pressure or temperature profile can lead to seal failure. It is not a one-size-fits-all solution.

The Impact of Long-Term Performance

The exceptional durability of PTFE gaskets leads to a long product life, even under continuous use.

This quality significantly minimizes equipment downtime and reduces long-term maintenance costs, a critical financial consideration in the power industry.

Making the Right Choice for Your Goal

The selection of a PTFE gasket should be driven by the specific demands of the application.

- If your primary focus is electrical safety: Prioritize PTFE gaskets with certified high dielectric strength for use in high-voltage equipment like transformers and switch cabinets.

- If your primary focus is operational uptime: Choose gaskets engineered to withstand the specific temperature, pressure, and vibration profiles of your rotating equipment to minimize maintenance cycles.

- If your primary focus is process efficiency: Select a gasket whose form and material structure are designed to create a perfect, impermeable seal in your specific fluid or gas transfer systems.

Ultimately, leveraging the correct PTFE gasket is a strategic decision to enhance the safety, reliability, and longevity of your energy infrastructure.

Summary Table:

| Property | Benefit for Energy & Power Industry |

|---|---|

| Excellent Electrical Insulation | Prevents arcing and short circuits in high-voltage equipment like transformers and switchgear. |

| High-Temperature Resistance | Maintains seal integrity and performance in extreme heat environments. |

| Chemical Inertness | Resists corrosion and prevents contamination of system fluids/gases. |

| Vibration Absorption | Withstands mechanical stress in rotating equipment like generators for long-term stability. |

| Impermeable Sealing | Creates leak-proof barriers in fluid and gas transfer systems, maximizing efficiency and safety. |

Enhance Your Power Infrastructure with Precision PTFE Components

Your energy and power systems demand components that guarantee safety, reliability, and maximum uptime. KINTEK specializes in the precision manufacturing of high-performance PTFE components—including seals, gaskets, liners, and custom labware—specifically for the semiconductor, medical, laboratory, industrial, and other specialized industries.

We understand the critical role a PTFE gasket plays in your operations. Let us provide you with a solution that ensures:

- Unmatched Safety: Superior dielectric strength for high-voltage applications.

- Operational Excellence: Components engineered to withstand extreme temperatures, pressures, and vibrations.

- Long-Term Value: Durable products that reduce maintenance cycles and minimize costly downtime.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your unique requirements.

Ready to secure the reliability of your critical infrastructure? Contact KINTEK today to discuss your project and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments