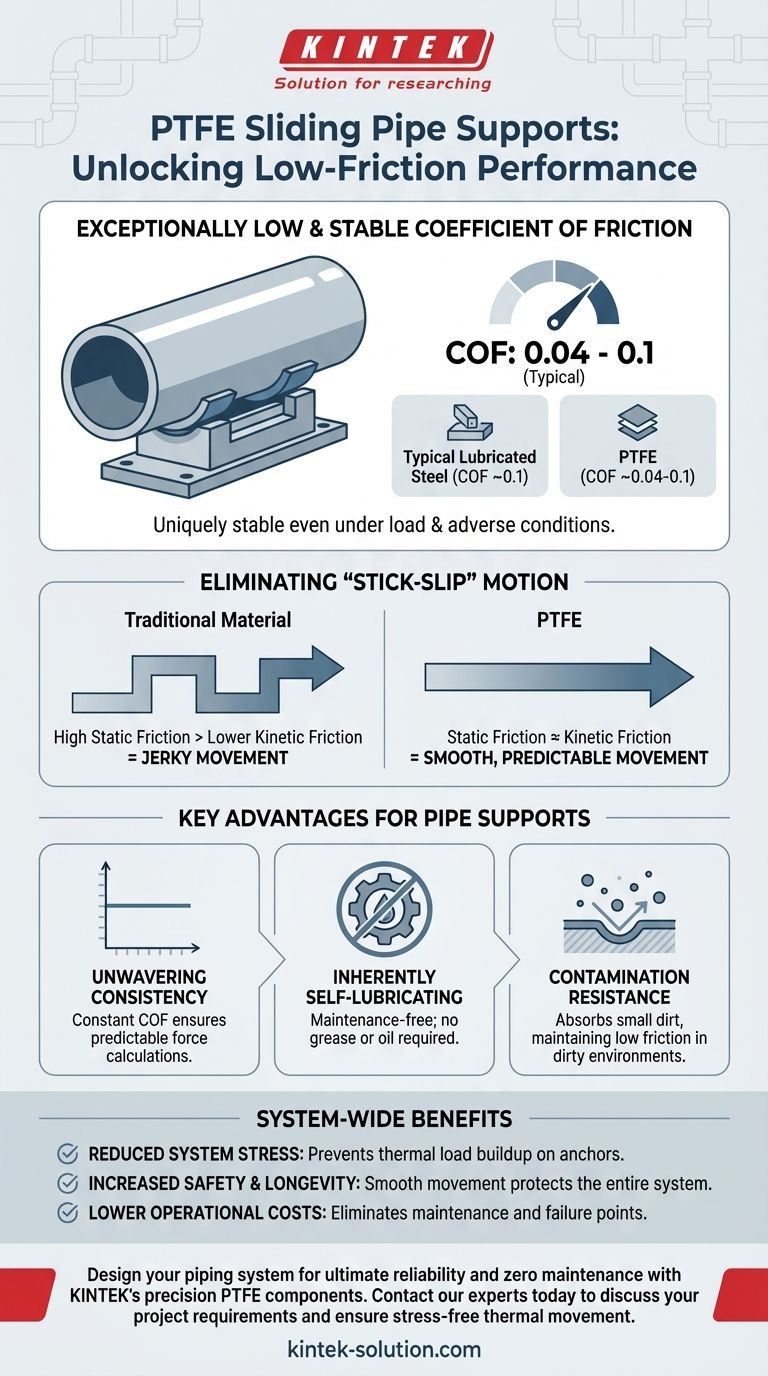

In short, the coefficient of friction in PTFE sliding pipe supports is exceptionally low and uniquely stable. For typical low-speed movement caused by thermal expansion, the friction coefficient is around 0.1, and can be as low as 0.04. Crucially, this value remains constant even under significant load and adverse conditions, ensuring predictable performance.

The core advantage of PTFE in pipe supports is not just its low friction, but its consistency. Unlike other materials, its static and kinetic friction coefficients are nearly identical, which prevents the damaging "stick-slip" effect and allows for smooth, low-stress movement.

The Defining Characteristics of PTFE Friction

To understand why PTFE is a superior material for this application, we need to look beyond a single number and examine its unique frictional behavior.

Exceptionally Low Coefficient

PTFE, commonly known by the brand name Teflon, has one of the lowest coefficients of friction of any solid material. Values are often cited between 0.04 and 0.1.

To put this in perspective, lubricated steel can have a static coefficient of friction of 0.1 and a kinetic value of 0.05. PTFE's performance rivals or exceeds even well-lubricated metal-on-metal contact, but without the need for any external lubricant.

Unwavering Consistency

The most critical factor for engineering design is predictability. The references emphasize that PTFE's coefficient of friction remains constant, even under worst-case conditions.

This means engineers can confidently calculate the forces exerted on pipe anchors and building structures as the pipe expands and contracts, without having to account for unpredictable friction spikes.

Preventing "Stick-Slip"

In many materials, the static friction (the force needed to start movement) is higher than the kinetic friction (the force needed to keep it moving). This difference causes a jerky, "stick-slip" motion.

PTFE's static and kinetic coefficients are almost the same. This eliminates stick-slip, ensuring that as thermal stresses build in a pipe, it begins to move smoothly and gradually, preventing the sudden release of energy that can damage the system.

Why This Behavior is Critical for Pipe Supports

The unique properties of PTFE directly address the fundamental challenges of supporting large piping systems that are subject to thermal expansion and contraction.

Inherently Self-Lubricating

PTFE's low friction is an intrinsic property of the material itself. It requires no grease or oil, making the pipe supports maintenance-free for their entire service life.

This eliminates a common point of failure and reduces long-term operational costs.

Resistance to Contamination

Industrial environments are often dirty. Traditional lubricated supports can attract dust and grime, which increases friction and can cause the support to seize.

PTFE is not only non-stick but also has the ability to absorb small dirt particles into its surface. This unique characteristic allows it to maintain its low-friction properties even in less-than-ideal conditions.

Reducing System-Wide Stress

The primary function of a sliding pipe support is to allow the pipe to move freely, thereby preventing the buildup of dangerous thermal stress.

By providing a consistently low-friction surface, PTFE ensures that the pipe's movement is never constrained. This reduces wear on the pipe and support, lowers the forces transferred to the support structure, and ultimately improves the safety and longevity of the entire system.

Making the Right Choice for Your Goal

When designing or evaluating a piping system, the choice of support material has significant long-term consequences.

- If your primary focus is system safety and integrity: PTFE's constant, low coefficient of friction ensures that thermal expansion stresses are never unexpectedly transferred to anchors and structures.

- If your primary focus is minimizing lifetime operational cost: The self-lubricating and maintenance-free nature of PTFE eliminates the labor and material costs associated with traditional lubricated supports.

- If your primary focus is reliability in a harsh environment: PTFE's ability to perform in dirty conditions without seizing makes it a far more dependable choice than greased alternatives.

Ultimately, specifying PTFE sliding supports is a decision for predictable, reliable, and maintenance-free performance over the entire life of your system.

Summary Table:

| Property | PTFE Sliding Support Behavior | Benefit for Piping Systems |

|---|---|---|

| Coefficient of Friction | Consistently low (0.04 - 0.1) | Reduces stress on pipes and anchors |

| Static vs. Kinetic Friction | Nearly identical values | Eliminates damaging stick-slip motion |

| Performance Under Load | Remains constant | Ensures predictable, reliable movement |

| Maintenance | Self-lubricating, no grease required | Lowers lifetime operational costs |

Design your piping system for ultimate reliability and zero maintenance with KINTEK's precision PTFE components.

Our custom-fabricated PTFE seals, liners, and labware are engineered to deliver the consistent, low-friction performance detailed in this article. For semiconductor, medical, laboratory, and industrial applications, trust KINTEK to provide the durable solutions you need—from prototypes to high-volume production.

Contact our experts today to discuss your project requirements and ensure stress-free thermal movement.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications