At its core, PTFE's low thermal conductivity means it cannot effectively dissipate heat away from the cutting tool. This causes heat to build up in a concentrated area, leading to significant thermal expansion, material deformation, and a loss of dimensional accuracy in the final part.

The central challenge in machining PTFE is not its hardness, but its unique combination of properties: it acts as a thermal insulator that is also soft and expands dramatically with heat. Success requires a strategic shift from aggressive material removal to meticulous heat management and support for the material's inherent flexibility.

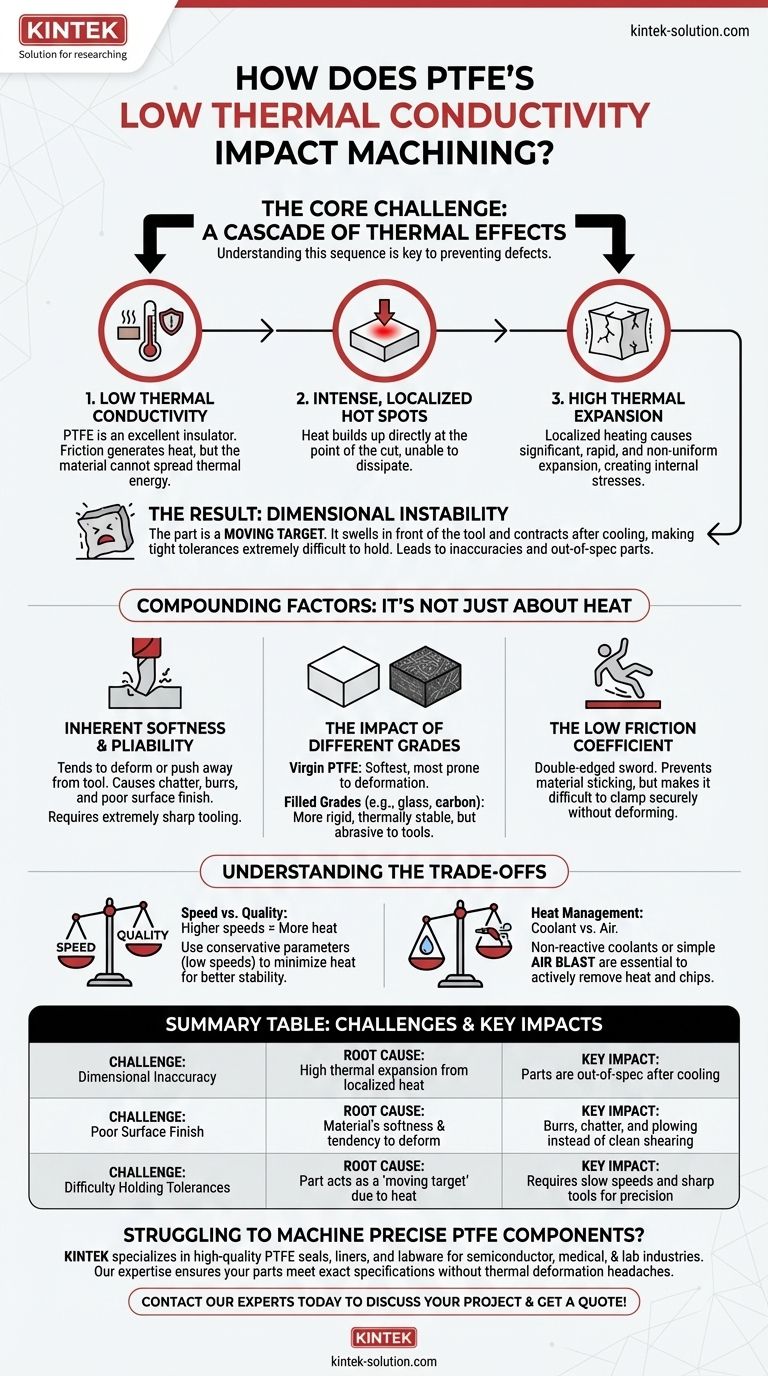

The Core Challenge: A Cascade of Thermal Effects

The primary difficulty when machining Polytetrafluoroethylene (PTFE) stems from a chain reaction initiated by its poor thermal performance. Understanding this sequence is key to preventing defects.

Low Thermal Conductivity

PTFE is an excellent thermal insulator. During machining, the friction from the cutting tool generates heat, but the material is incapable of spreading that thermal energy throughout its mass.

This results in intense, localized hot spots directly at the point of the cut.

High Thermal Expansion

The second part of the problem is PTFE's very high coefficient of thermal expansion. When the localized area heats up, it expands significantly more than a comparable metal would.

This expansion happens rapidly and is not uniform across the part, creating internal stresses and immediate dimensional changes.

The Result: Dimensional Instability

The combination of trapped heat and high expansion means the part you are cutting is a moving target.

As the tool moves, the material swells in front of it and contracts after it cools, making it extremely difficult to hold tight tolerances. This leads directly to inaccuracies and parts that may be in-spec while warm but out-of-spec once they return to ambient temperature.

Compounding Factors: It's Not Just About Heat

While thermal issues are the primary driver of problems, other inherent properties of PTFE complicate the machining process further.

Inherent Softness and Pliability

PTFE is a very soft material. Instead of shearing cleanly like a rigid plastic or metal, it has a tendency to deform or push away from the cutting tool.

This can lead to tool chatter, burr formation, and a poor surface finish. It requires extremely sharp tooling to ensure you are cutting the material rather than plowing through it.

The Impact of Different Grades

Not all PTFE is the same. Virgin PTFE is the softest and most prone to deformation.

Filled grades, such as glass-filled or carbon-filled PTFE, are much more rigid and thermally stable. This added strength makes them easier to machine to tight tolerances, though the fillers themselves can be abrasive and increase tool wear.

The Low Friction Coefficient

PTFE's famously low coefficient of friction is a double-edged sword. It helps prevent material from sticking to the cutting tool, which is a significant benefit.

However, this same slipperiness can make it difficult to clamp the workpiece securely without deforming it, requiring careful consideration of workholding techniques.

Understanding the Trade-offs

Successfully machining PTFE requires acknowledging the compromises between speed, finish, and material choice. Rushing the process or using the wrong approach will invariably lead to failed parts.

"Easy to Cut" vs. "Easy to Get Right"

PTFE's softness makes it feel "easy to cut" because material removal requires very little force. However, this is deceptive.

The real challenge is not removing material, but doing so with precision. The properties that make it easy to cut also make it difficult to achieve dimensional accuracy.

Speed vs. Quality

Higher cutting speeds and feeds generate more heat. With PTFE, this is the primary enemy of precision.

You must use conservative cutting parameters, often at lower speeds (300-500 surface feet per minute), to minimize heat generation. What you lose in cycle time, you gain in dimensional stability and surface quality.

Heat Management: Coolant vs. Air

Using a coolant is essential for managing heat buildup. Non-reactive liquid coolants are effective, but a simple air blast is often sufficient and preferred to avoid chemical contamination of the part.

The goal is not just to cool the part, but to actively remove chips that can trap heat against the surface.

Making the Right Choice for Your Goal

Success depends on adapting your technique to counter the material's specific properties. Tailor your approach based on what matters most for your application.

- If your primary focus is dimensional accuracy: Prioritize aggressive heat management by using a coolant or air blast, employing extremely sharp tools, and using slow, conservative cutting speeds.

- If your primary focus is surface finish: Use tools with a very high rake and sharp cutting edge to ensure you are shearing the material cleanly, and take light finishing passes to minimize tool pressure.

- If your primary focus is mechanical stability: Choose a filled grade of PTFE (like glass or carbon-filled) from the outset, as its inherent rigidity makes it far less susceptible to thermal deformation.

By treating PTFE as a unique thermal and mechanical challenge, you can consistently produce precise and reliable components.

Summary Table:

| Challenge | Root Cause | Key Impact |

|---|---|---|

| Dimensional Inaccuracy | High thermal expansion from localized heat | Parts are out-of-spec after cooling |

| Poor Surface Finish | Material's softness & tendency to deform | Burrs, chatter, and plowing instead of clean shearing |

| Difficulty Holding Tolerances | Part acts as a "moving target" due to heat | Requires slow speeds and sharp tools for precision |

Struggling to machine precise PTFE components? KINTEK specializes in manufacturing high-quality PTFE seals, liners, and labware for the semiconductor, medical, and laboratory industries. Our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures your parts meet exact specifications without the headaches of thermal deformation. Contact our experts today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials