In short, PTFE envelope gaskets are preferred because their unique combination of properties directly solves the primary challenge of the food and pharmaceutical industries: ensuring absolute product purity. Their chemical inertness, non-toxic nature, and resistance to contamination make them one of the safest materials for direct contact with consumable and medical products, aligning perfectly with strict regulatory standards like those from the FDA.

The choice of a gasket in these industries is not merely a mechanical decision about sealing a joint; it's a critical safety decision about protecting the product from contamination. PTFE's properties make it a reliable safeguard for product integrity.

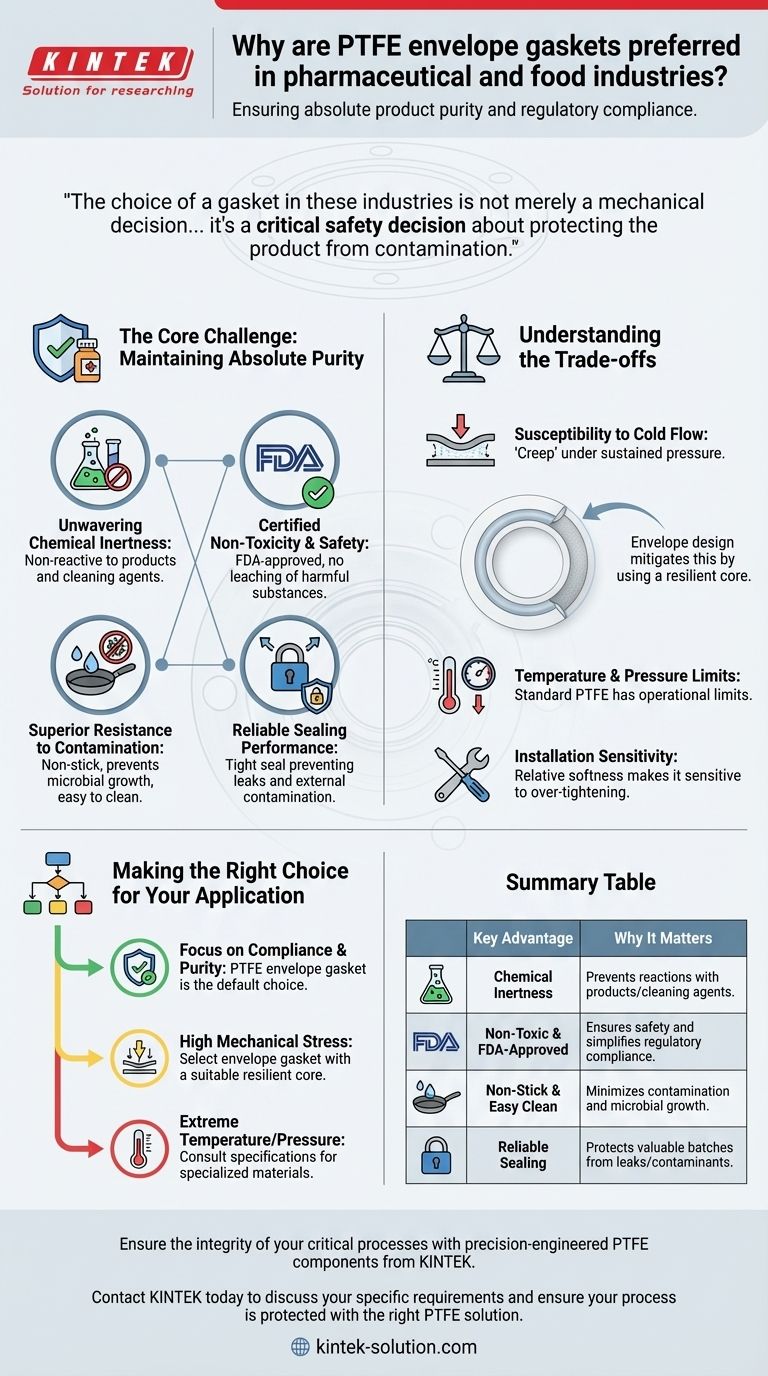

The Core Challenge: Maintaining Absolute Purity

In pharmaceutical manufacturing and food processing, even the slightest contamination can compromise an entire batch, leading to significant financial loss and potential public health risks. Gaskets are a critical control point, and PTFE's characteristics make it an ideal material for this role.

### Unwavering Chemical Inertness

A primary requirement is that the gasket material must not react with the product or any cleaning agents.

PTFE is one of the most non-reactive substances known. This inertness ensures that it will not alter the chemical composition of sensitive drugs or food ingredients it comes into contact with. It also withstands aggressive sterilization and clean-in-place (CIP) chemicals without degrading.

### Certified Non-Toxicity and Safety

The gasket must not introduce any harmful substances into the process stream.

PTFE is non-toxic and FDA-approved for food contact. It does not leach chemicals or contaminants, ensuring the final product remains pure and safe for consumption. This is a fundamental requirement for passing regulatory audits.

### Superior Resistance to Contamination

A gasket's surface can be a breeding ground for microbes if not designed properly.

PTFE has excellent non-stick properties, which prevent process media from adhering to its surface. This quality, combined with its resistance to bacterial growth and the fact it does not adsorb materials, makes it easy to clean and minimizes the risk of cross-contamination between batches.

### Reliable Sealing Performance

While material purity is paramount, the gasket must still perform its primary function: preventing leaks.

PTFE envelope gaskets provide a tight, reliable seal for various flange types, including glass-lined and metal systems. This prevents leakage of valuable products and stops external contaminants from entering the system.

Understanding the Trade-offs

While PTFE is a superior choice for these applications, no material is perfect. Acknowledging its limitations is key to using it effectively.

### Susceptibility to Cold Flow

The most well-known limitation of solid PTFE is "creep" or "cold flow." Under sustained pressure and temperature, the material can deform, potentially loosening the seal over time.

PTFE envelope gaskets are designed specifically to mitigate this issue. They use a soft, resilient core material (like rubber or non-asbestos fiber) protected by a thin outer layer of PTFE, combining the chemical resistance of PTFE with the mechanical stability of the core.

### Temperature and Pressure Limits

While robust, PTFE has operational limits. Standard PTFE gaskets are not suitable for extremely high-temperature or high-pressure applications where metallic or semi-metallic gaskets might be required.

### Installation Sensitivity

The relative softness of PTFE makes it more susceptible to damage from improper installation. Over-tightening a flange can crush the gasket, compromising the seal and potentially damaging the PTFE envelope itself.

Making the Right Choice for Your Application

Selecting the right gasket involves balancing regulatory compliance, chemical compatibility, and mechanical performance.

- If your primary focus is regulatory compliance and product purity: A PTFE envelope gasket is the default, industry-standard choice for most food and pharmaceutical processes.

- If your process involves high mechanical stress or pressure cycling: Ensure you select an envelope gasket with a suitable core material designed to resist creep and maintain a strong seal.

- If your application pushes the boundaries of temperature and pressure: You may need to consult specifications for specialized PTFE compounds or consider alternative high-performance materials.

Ultimately, specifying a PTFE envelope gasket is a strategic decision to uphold the highest standards of safety and quality in critical manufacturing environments.

Summary Table:

| Key Advantage | Why It Matters for Pharma & Food |

|---|---|

| Chemical Inertness | Prevents reaction with sensitive products and harsh cleaning agents. |

| Non-Toxic & FDA-Approved | Ensures product safety and simplifies regulatory compliance. |

| Non-Stick & Easy Clean | Minimizes contamination risk and prevents microbial growth. |

| Reliable Sealing | Protects valuable batches from leaks and external contaminants. |

Ensure the integrity of your critical processes with precision-engineered PTFE components from KINTEK.

As detailed in this article, the right sealing solution is paramount for product purity and regulatory compliance in the pharmaceutical, food, laboratory, and semiconductor industries. KINTEK specializes in manufacturing high-quality, custom PTFE components—including seals, gaskets, liners, and labware—that meet the stringent demands of your application.

We combine precision production with expert custom fabrication, from prototypes to high-volume orders, to deliver solutions you can trust.

Contact KINTEK today to discuss your specific requirements and ensure your process is protected with the right PTFE solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries