At its core, a spring-energized seal is a high-performance sealing device composed of a durable polymer jacket, typically PTFE, and a corrosion-resistant metal spring energizer. The spring applies a constant force to the PTFE jacket, pressing its sealing lips firmly against the mating surfaces. This mechanism creates a highly reliable barrier that prevents leaks even under extreme operating conditions.

The fundamental advantage of a spring-energized seal is its ability to provide a constant, active sealing force. Unlike traditional elastomeric seals that can fail due to wear, temperature changes, or compression set, the internal spring continuously compensates for these factors to maintain a leak-proof connection.

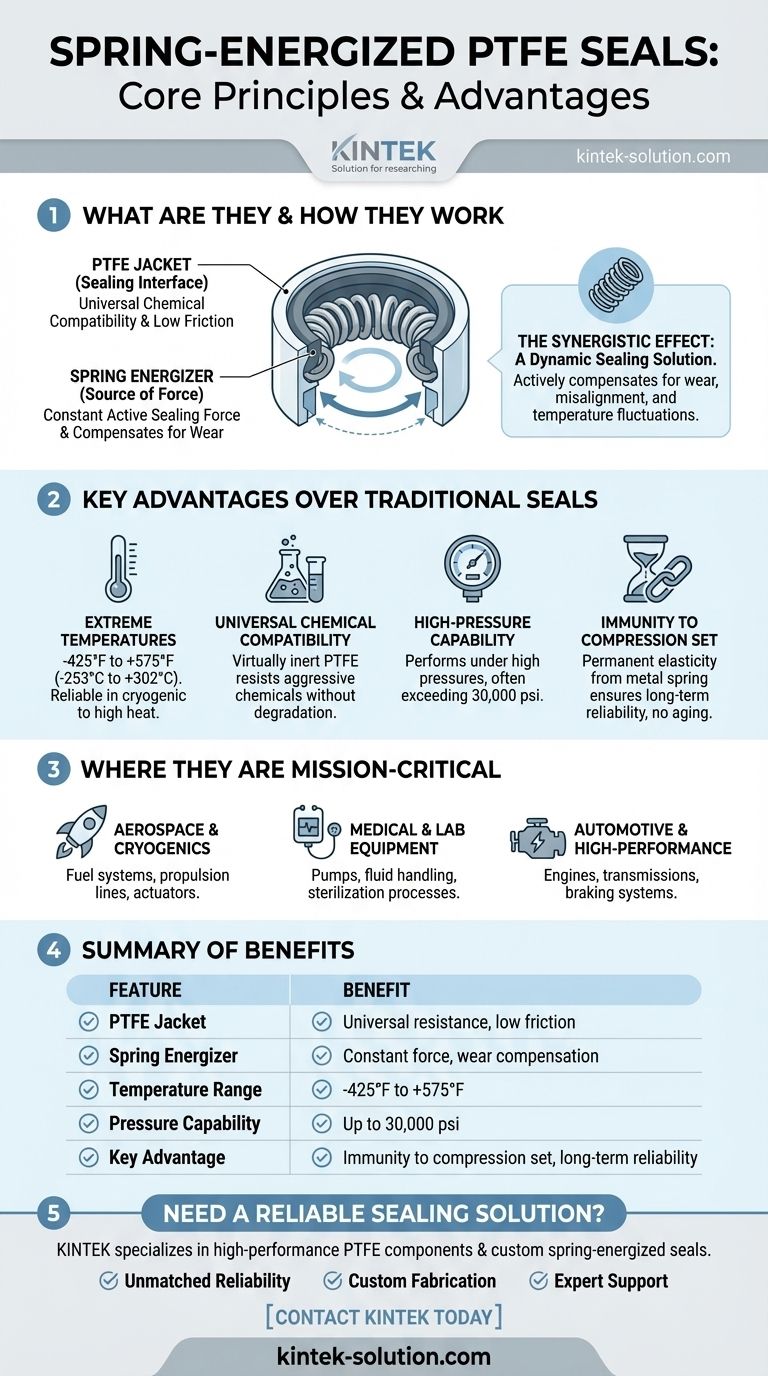

How a Spring-Energized Seal Delivers Superior Performance

The effectiveness of this seal comes from the synergy between its two primary components. Each part plays a distinct but complementary role in creating a robust and resilient seal.

The PTFE Jacket: The Sealing Interface

The outer jacket is made from Polytetrafluoroethylene (PTFE) or a similar high-performance polymer. This material is chosen for its exceptional properties.

PTFE provides universal chemical compatibility, making it resistant to nearly all acids, solvents, and corrosive fluids. It also has a very low coefficient of friction, which reduces wear and energy loss in dynamic applications without requiring lubrication.

The Spring Energizer: The Source of Force

Inside the jacket sits a metal spring. This spring acts as the engine of the seal, providing the mechanical energy required for effective sealing.

When the seal is installed, the spring is compressed, creating a constant radial force. This force pushes the soft PTFE lips outward, ensuring tight contact with the sealing gland even at low pressures.

The Synergistic Effect: A Dynamic Seal

The spring's true value is its ability to create a dynamic sealing solution. It actively compensates for factors that cause traditional seals to fail.

This includes adjusting for seal lip wear over time, gland misalignment, and dimensional changes caused by extreme temperature fluctuations, from cryogenic lows to high-temperature highs.

Key Advantages Over Traditional Seals

Spring-energized seals are specified when standard elastomeric seals like O-rings cannot meet the demands of the application. Their design offers several distinct capabilities.

Extreme Temperature and Cryogenic Service

These seals function reliably across an exceptionally wide temperature range, from cryogenic conditions at -425°F (-253°C) up to high-temperature service at 575°F (302°C).

Universal Chemical Compatibility

The PTFE jacket is virtually inert, allowing these seals to be used in the most aggressive chemical environments without degradation.

High-Pressure Capability

The spring's constant force, combined with system pressure, enables these seals to perform under high-pressure ratings, often exceeding 30,000 psi.

Immunity to Compression Set and Aging

Unlike rubber, the metal spring provides permanent elasticity. The seal will not take a "compression set" or become brittle with age, ensuring long-term performance and reliability.

Understanding the Trade-offs

While they offer superior performance, these seals represent a more specialized engineering solution than a standard O-ring, which comes with certain considerations.

Precision Gland Design

To function optimally, spring-energized seals require precise machining of the gland (the housing they sit in). The tolerances are typically tighter than those for a simple elastomeric seal.

Higher Initial Cost

Their multi-component construction and high-performance materials mean they are a more significant investment upfront compared to commodity seals. This cost is justified by their extended service life and reliability in critical applications.

Where These Seals Are Mission-Critical

The unique capabilities of spring-energized PTFE seals make them the preferred choice in industries where sealing failure is not an option.

Aerospace and Cryogenics

They are essential in fuel systems, cryogenic propulsion lines, and actuators. Their ability to handle extreme temperatures, high-altitude vacuums, and low outgassing properties is critical.

Medical and Laboratory Equipment

Used in pumps and fluid handling systems, their chemical resistance is vital for withstanding harsh sterilization processes. They ensure a hermetic seal that prevents contamination.

Automotive and High-Performance Systems

In engines, transmissions, and braking systems, they provide reliable sealing under intense pressure and temperature fluctuations while minimizing frictional losses for improved efficiency.

Making the Right Choice for Your Goal

Selecting the correct seal depends entirely on the operational demands of your application.

- If your primary focus is extreme temperature or chemical resistance: A spring-energized PTFE seal is often the only viable option, as traditional elastomers would quickly degrade.

- If your primary focus is high-pressure or high-speed dynamic sealing: The low-friction PTFE and constant spring force provide superior longevity and performance over standard seals.

- If your primary focus is long-term reliability in a critical system: The seal's immunity to compression set and its ability to compensate for wear make it the ideal choice for minimizing maintenance and preventing failure.

Ultimately, choosing a spring-energized seal is an investment in unparalleled reliability for your most demanding applications.

Summary Table:

| Feature | Benefit |

|---|---|

| PTFE Jacket | Universal chemical resistance, low friction, no lubrication needed |

| Spring Energizer | Constant sealing force, compensates for wear and temperature changes |

| Temperature Range | -425°F to +575°F (-253°C to +302°C) |

| Pressure Capability | Up to 30,000 psi |

| Key Advantage | Immunity to compression set and long-term reliability in critical systems |

Need a reliable sealing solution for extreme conditions?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom spring-energized seals. We serve the semiconductor, medical, laboratory, and industrial sectors, providing solutions from prototypes to high-volume production.

Our seals are engineered to deliver:

- Unmatched Reliability: Prevent leaks in your most critical applications.

- Custom Fabrication: Get a perfect fit for your specific gland design and operational demands.

- Expert Support: Leverage our expertise in material science and sealing technology.

Contact KINTECK today to discuss your project requirements and ensure leak-proof performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs