In short, the primary limitations of PTFE bellows are their lack of mechanical strength for high-pressure applications, poor resistance to abrasion, and higher cost compared to alternatives like rubber. While renowned for chemical inertness, they are also vulnerable to specific high-energy radiation and a small number of highly reactive chemical agents.

The core takeaway is that PTFE's exceptional chemical resistance and flexibility come at a direct trade-off with its mechanical robustness. Understanding these limitations is not about dismissing PTFE, but about deploying it precisely where its unique strengths can be fully leveraged without risking structural failure.

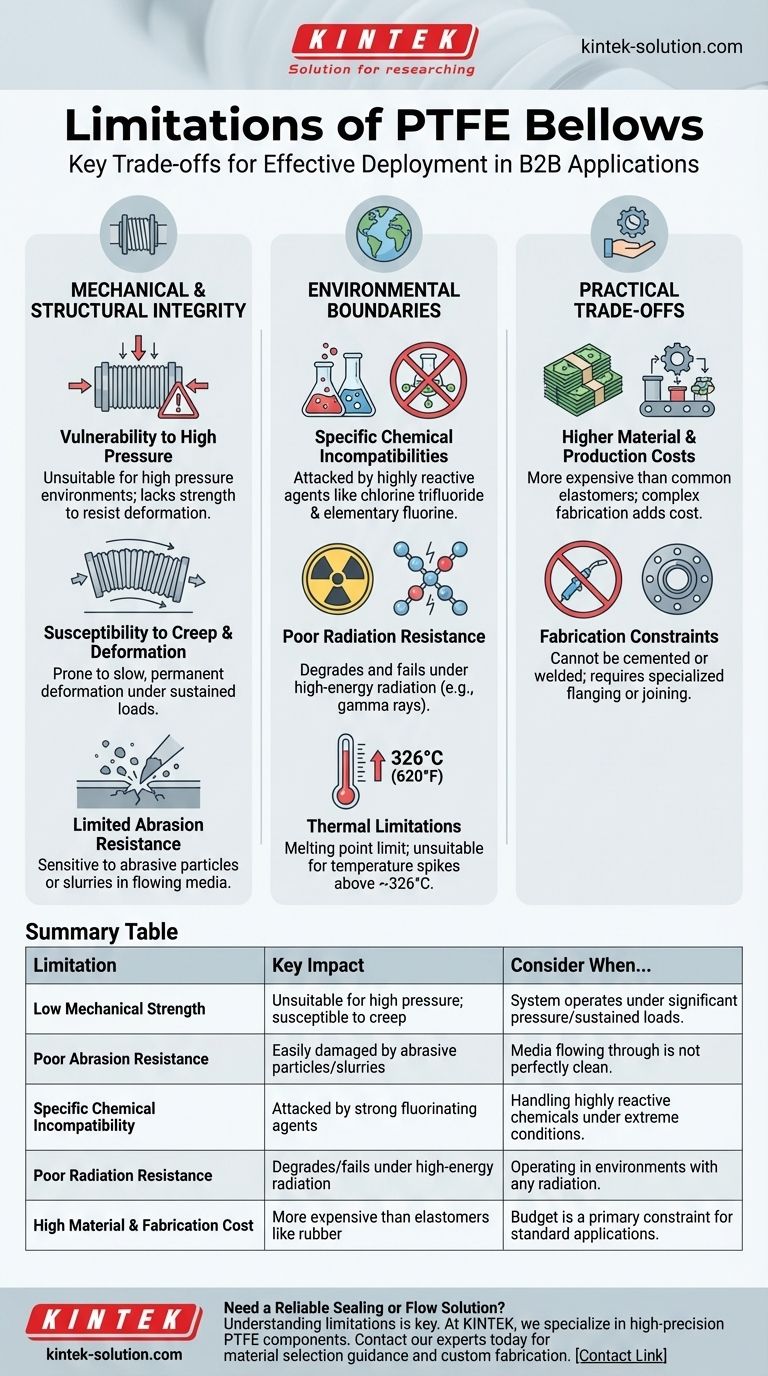

The Core Challenge: Mechanical and Structural Integrity

While PTFE offers incredible flexibility, its primary drawbacks stem from its inherent softness and lack of rigidity compared to metals or even some composite materials.

Vulnerability to High Pressure

PTFE bellows lack the mechanical strength to handle high-pressure environments. The material's natural tendency to deform means it is unsuitable for applications where significant internal or external pressure is a constant.

Susceptibility to Creep and Deformation

Even under moderate, sustained loads, PTFE is susceptible to creep—a slow, permanent deformation. This lack of sturdiness means the bellows can lose their shape and integrity over time, compromising the entire system.

Limited Abrasion Resistance

The same low-friction surface that makes PTFE non-stick also makes it sensitive to abrasion. If the media flowing through the system contains abrasive particles or slurries, the bellows' surface can be quickly damaged, leading to premature failure.

Understanding the Environmental Boundaries

PTFE is not universally invulnerable. Its performance is bounded by specific chemical, radiological, and thermal conditions that must be respected.

Specific Chemical Incompatibilities

Despite its reputation for being nearly chemically inert, PTFE can be attacked by a few highly reactive agents. These include chlorine trifluoride, elementary fluorine, and other strong fluorinating agents, especially under conditions of high pressure and temperature.

Poor Radiation Resistance

PTFE has poor resistance to high-energy radiation, such as gamma rays. This type of radiation can cause molecular breakdown, breaking the polymer chains and leading to a catastrophic loss of mechanical properties.

Thermal Limitations

The melting point of PTFE is approximately 326°C (620°F). While this is high for a polymer, it represents a hard ceiling that makes it unsuitable for applications that experience temperature spikes above this limit.

The Practical Trade-offs: Cost and Fabrication

Beyond technical performance, the practical aspects of using PTFE present their own set of limitations.

Higher Material and Production Costs

Compared to common elastomers like rubber or certain composites, PTFE is a more expensive material. The processes required to form it into complex bellow shapes also contribute to a higher overall component cost.

Fabrication Constraints

A significant practical limitation is that PTFE cannot be cemented or welded in the traditional sense. This makes integrating the bellows into a larger system more complex, often requiring specialized flanging or mechanical joining methods.

Making the Right Choice for Your Application

Selecting the correct material requires balancing performance needs with environmental realities.

- If your primary focus is handling highly corrosive chemicals at low pressure: PTFE is likely an ideal choice due to its unmatched chemical inertness and flexibility.

- If your system involves high pressure or abrasive slurries: You must consider more robust alternatives like metal bellows or reinforced composites to prevent mechanical failure.

- If your environment involves high-energy radiation: PTFE should be avoided entirely, as the material will degrade and fail.

- If budget is the primary driver for a standard application: Elastomers like rubber may offer a more cost-effective solution, provided they meet the necessary chemical resistance requirements.

Ultimately, recognizing the precise boundaries of PTFE's capabilities is the key to using it effectively and reliably.

Summary Table:

| Limitation | Key Impact | Consider When... |

|---|---|---|

| Low Mechanical Strength | Unsuitable for high-pressure applications; susceptible to creep. | Your system operates under significant pressure or sustained loads. |

| Poor Abrasion Resistance | Easily damaged by abrasive particles or slurries. | The media flowing through is not perfectly clean. |

| Specific Chemical Incompatibility | Attacked by strong fluorinating agents (e.g., chlorine trifluoride). | Handling highly reactive chemicals under extreme conditions. |

| Poor Radiation Resistance | Degrades and fails when exposed to high-energy radiation (e.g., gamma rays). | Operating in environments with any level of radiation. |

| High Material & Fabrication Cost | More expensive than elastomers like rubber. | Budget is a primary constraint for a standard application. |

Need a Reliable Sealing or Flow Solution?

Understanding material limitations is the first step to a successful design. At KINTEK, we specialize in manufacturing high-precision PTFE components (including custom bellows, seals, liners, and labware) for the semiconductor, medical, laboratory, and industrial sectors.

We help you navigate these trade-offs by:

- Providing Expert Material Selection Guidance: Our team can help determine if PTFE is right for your specific chemical, pressure, and temperature requirements.

- Offering Custom Fabrication: From initial prototypes to high-volume production, we create components tailored to your exact specifications, ensuring optimal performance and reliability.

Let's find the optimal solution for your application. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What processing methods are typically used for PTFE? Mastering the Unique Path from Powder to Precision Part

- What is PTFE packing and what is its primary use? The Ultimate Sealing Solution for Harsh Environments

- Why are PTFE lined butterfly valves popular in industrial applications? Unmatched Chemical Resistance & Reliability

- Which type of PTFE gasket is better for uneven surfaces or fragile flanges? Seal with Confidence Using ePTFE

- What are the strength and durability characteristics of stainless steel impellers? Superior Mechanical & Thermal Performance

- What are the key benefits of using PTFE for seals? Unlock Superior Performance in Extreme Conditions

- What are the common challenges in PTFE machining related to tool wear? How to Extend Tool Life and Cut Costs

- What temperature range can PTFE balls withstand? Unlock Extreme Thermal Stability from -200°C to 260°C