Beyond the standard product, key offerings for Teflon-encapsulated O-rings center on a comprehensive support system designed for high-stakes applications. These services include expert design and engineering assistance, custom prototyping and manufacturing, specialized fulfillment and support, and tailored inventory management solutions to ensure the correct component is deployed effectively.

The true value of Teflon-encapsulated O-rings lies not just in the component itself, but in the ecosystem of engineering and logistical support required to leverage its unique combination of chemical inertness and mechanical flexibility in demanding environments.

What Defines a Teflon-Encapsulated O-Ring?

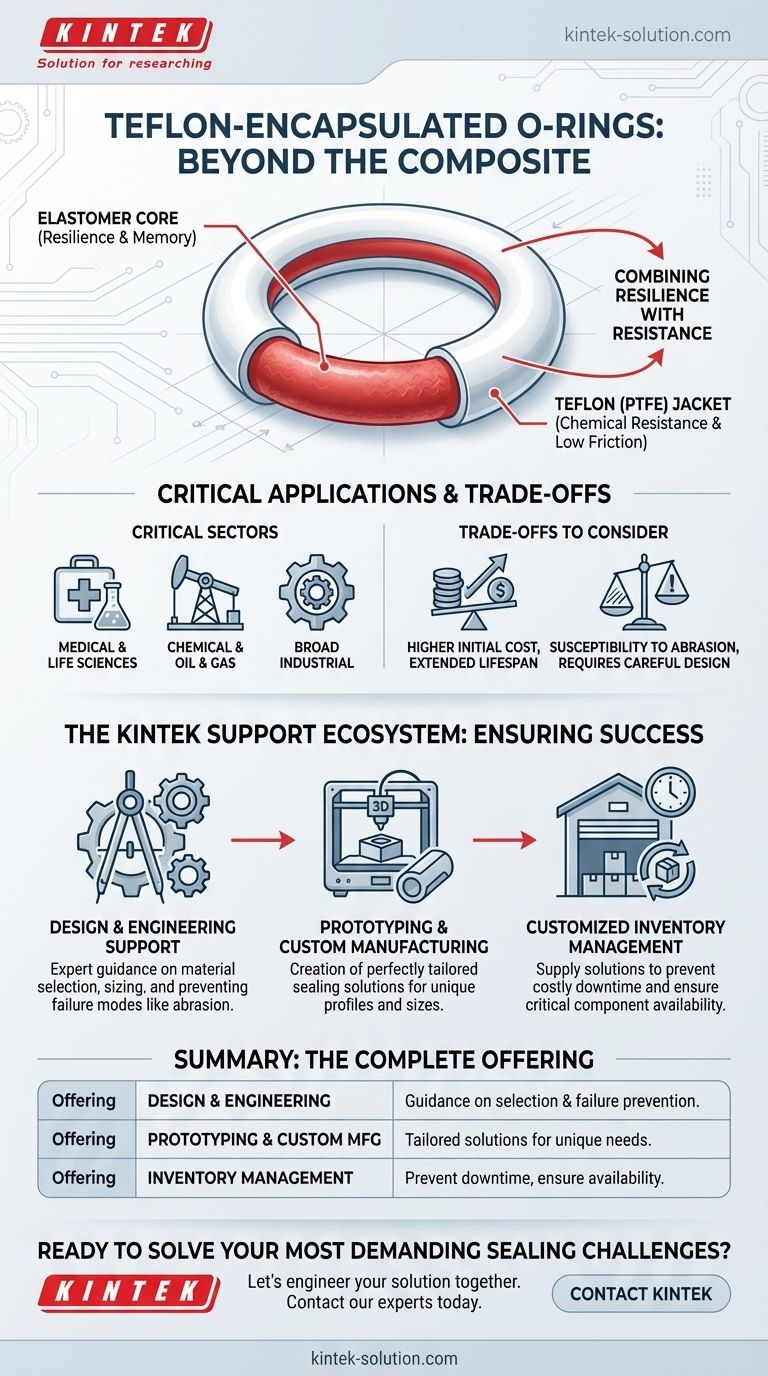

Teflon-encapsulated O-rings are composite seals engineered for performance where standard elastomers would fail. They solve a fundamental material science challenge by merging two distinct materials into a single, superior component.

The Core and the Jacket

At the center is an elastomer core, typically made of Silicone or FKM (Viton®), which provides the flexibility, memory, and resilience needed to maintain a seal under pressure.

This core is completely enclosed within a seamless Teflon (PTFE) jacket, usually made from FEP or PFA resins. This outer shell is the key to the O-ring's exceptional performance.

Combining Resilience with Resistance

The design brilliantly combines the energizing force of a flexible elastomer with the near-universal chemical resistance and low-friction properties of Teflon.

The encapsulation protects the sensitive elastomer core from aggressive chemicals and extreme temperatures, drastically extending the O-ring's service life and operational range.

Adherence to Strict Quality Standards

The manufacturing of these components is a precise process. It involves careful material selection and advanced machinery, governed by strict quality assurance protocols from raw material sourcing to final inspection to ensure reliability.

Where Are These Components Critical?

The unique properties of Teflon-encapsulated O-rings make them indispensable across a wide range of mission-critical industries where seal failure is not an option.

Medical and Life Sciences

Their biocompatibility and resistance to aggressive cleaning agents make them ideal for medical devices. You will find them in infusion pumps, dialysis machines, and surgical tools, where they must comply with stringent FDA and USP Class VI standards.

Chemical Processing and Oil & Gas

In these sectors, seals are constantly exposed to harsh chemicals, high pressures, and extreme temperatures. The protective Teflon jacket prevents degradation that would quickly destroy a standard O-ring.

Broad Industrial Application

These O-rings are also deployed in food and beverage processing, heavy equipment hydraulics, and other industrial machinery where a combination of purity, durability, and chemical inertness is required.

Understanding the Trade-offs

While highly effective, these specialized components come with specific limitations that must be considered during the design phase to prevent premature failure.

Higher Initial Cost

The complex, multi-material construction makes Teflon-encapsulated O-rings more expensive than solid elastomer or solid Teflon alternatives. This cost is justified by their extended lifespan and performance in aggressive environments.

Susceptibility to Abrasion

The primary weakness is the Teflon jacket's relative softness. It is prone to scratching and physical damage in applications with abrasive media or sharp hardware edges, which can compromise the seal.

How Support Offerings Ensure Success

The trade-offs and specialized nature of these O-rings are precisely why suppliers provide more than just the part itself. The associated offerings are critical to their successful implementation.

Design and Engineering Support

Expert guidance is essential to select the correct core material, jacket type, and size for a specific application. Engineering assistance helps prevent common failure modes like abrasion or improper compression.

Prototyping and Custom Manufacturing

Many applications require unique sizes or profiles that are not available off-the-shelf. Prototyping and custom manufacturing capabilities allow for the creation of a perfectly tailored sealing solution.

Customized Inventory Management

For industries where downtime is catastrophic, managing the supply of critical components is vital. Suppliers offer custom inventory solutions to ensure that necessary seals are always available, preventing costly production delays.

Making the Right Choice for Your Application

Selecting the correct sealing solution requires balancing performance needs with operational realities.

- If your primary focus is extreme chemical resistance in a dynamic seal: An encapsulated O-ring is an excellent choice, but leveraging engineering support is crucial to ensure the design is optimized for your hardware.

- If your application involves significant abrasion or sharp edges: You must acknowledge the Teflon jacket's vulnerability and either redesign the hardware or explore alternative, more robust sealing materials.

- If you are managing a complex supply chain for critical equipment: Partner with a supplier offering customized inventory and fulfillment to mitigate risk and ensure operational continuity.

Understanding both the advanced component and the essential support system that surrounds it is the key to successful, reliable sealing in any demanding application.

Summary Table:

| Key Offering | Description |

|---|---|

| Design & Engineering Support | Expert guidance on material selection, sizing, and failure prevention. |

| Prototyping & Custom Manufacturing | Creation of tailored sealing solutions for unique applications. |

| Customized Inventory Management | Supply chain solutions to prevent downtime and ensure part availability. |

Ready to solve your most demanding sealing challenges?

At KINTEK, we don't just manufacture high-performance PTFE components like Teflon-encapsulated O-rings—we provide the essential engineering and logistical support to ensure your success. Our expertise in custom fabrication, from prototypes to high-volume orders, is tailored for the semiconductor, medical, laboratory, and industrial sectors.

Let's engineer your solution together. Contact our experts today to discuss your specific application needs.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main chemical resistance properties of PTFE-coated O-rings? Uncover the True Role of the Coating

- What are the benefits of using PTFE seals? Unmatched Chemical & Temperature Resistance

- Why are PTFE seals preferred over traditional rubber seals? Superior Performance in Extreme Conditions

- What are the advantages of PTFE-based seals? Unmatched Performance in Extreme Conditions

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals