While prized for their exceptionally low friction, PTFE (polytetrafluoroethylene) bushes possess significant disadvantages that make them unsuitable for many applications. Their primary drawbacks are a fundamental lack of mechanical strength, a high susceptibility to abrasive wear, greater cost compared to traditional materials, and notable manufacturing challenges.

The core issue with PTFE is that its greatest strengths—its softness and slipperiness—are also the source of its most critical weaknesses. It is a specialized material that excels in low-load, clean environments but fails when subjected to high pressure, abrasive conditions, or the need for rigid dimensional stability.

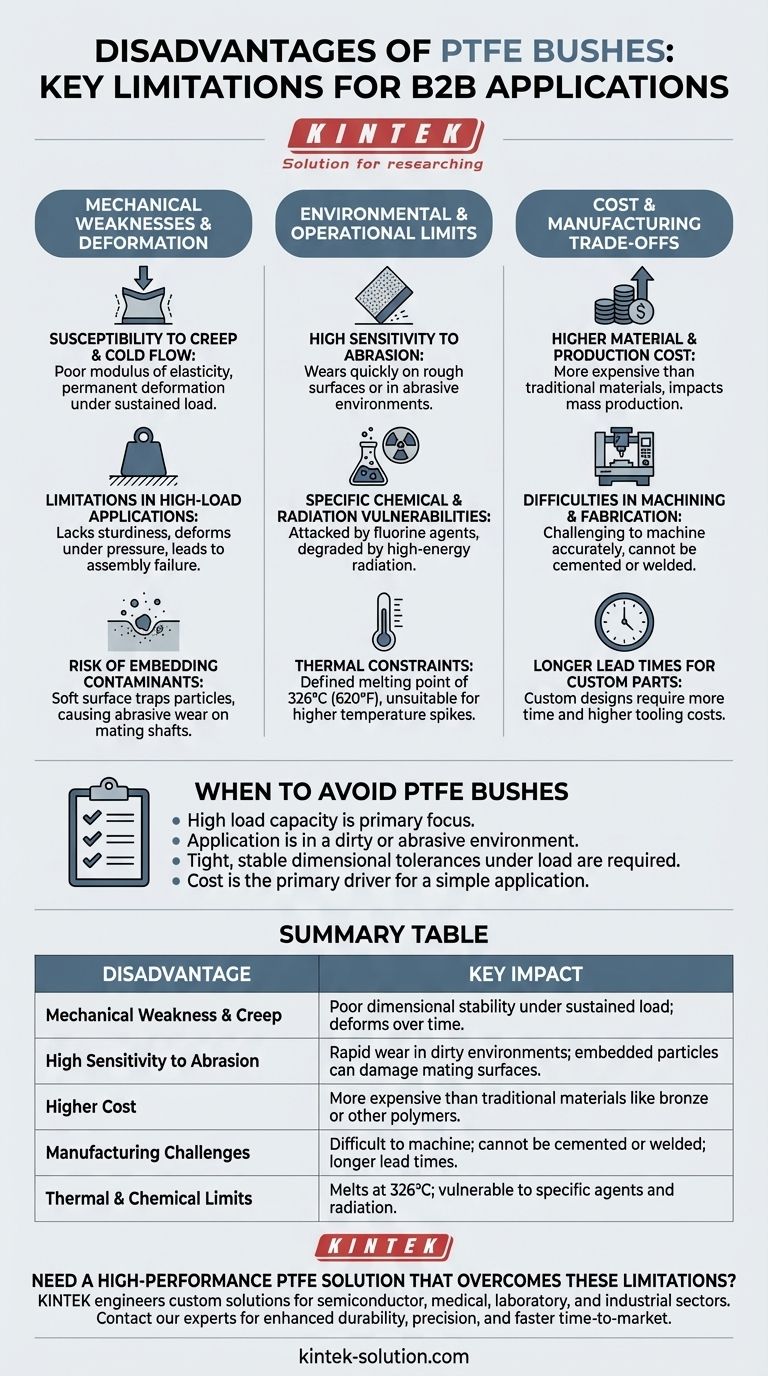

The Core Challenge: Mechanical Weakness and Deformation

The most significant limitation of PTFE is its poor mechanical performance compared to metal or even other engineering polymers. This weakness manifests in several critical ways.

Susceptibility to Creep and Cold Flow

PTFE has a poor modulus of elasticity and is highly susceptible to creep, also known as cold flow. This means that under a sustained load, even at room temperature, the material will slowly and permanently deform.

This property makes it unsuitable for applications requiring precise, long-term dimensional stability under pressure.

Limitations in High-Load Applications

Due to its softness and tendency to creep, PTFE is not a good choice for high-load or high-pressure applications. It simply lacks the sturdiness to support heavy forces without deforming, which can lead to a loss of tolerance and eventual failure of the assembly.

The Risk of Embedding Contaminants

The softness of PTFE presents a unique failure mode. Any small, hard particles of foreign matter, such as dirt or grit, that get between the bush and the shaft can become embedded in the PTFE surface.

Once embedded, these particles effectively turn the bushing into a piece of sandpaper, causing significant scoring and abrasive wear on the mating shaft or stanchion.

Environmental and Operational Limitations

Beyond its mechanical weaknesses, PTFE has specific vulnerabilities related to its operating environment and physical properties.

High Sensitivity to Abrasion

PTFE is not resistant to abrasion. Contact with a rough surface or the presence of abrasive media in the environment will cause the material to wear away quickly. Mating surfaces must be exceptionally smooth to ensure a long service life.

Specific Chemical and Radiation Vulnerabilities

While famous for its chemical resistance, PTFE is not invincible. It can be attacked by highly reactive agents like elemental fluorine, chlorine trifluoride, and other specific fluorinating agents, particularly at high temperatures and pressures.

Furthermore, it has poor resistance to high-energy radiation, which can cause the polymer's molecules to break down, degrading its material properties.

Thermal Constraints

Although PTFE has a high operating temperature for a polymer, it has a definitive melting point of 326°C (620°F). This is a hard limit that makes it unsuitable for applications that may experience temperature spikes above this point, unlike many metal bushings which can withstand far higher heat.

Understanding the Trade-offs: Cost and Manufacturing

The practical aspects of acquiring and implementing PTFE bushes also present significant disadvantages.

Higher Material and Production Cost

PTFE is generally more expensive than traditional bushing materials like bronze or many other polymers. This cost can be a major factor, especially in mass production scenarios.

Difficulties in Machining and Fabrication

PTFE is challenging to machine accurately due to its softness and thermal properties. It also cannot be cemented or welded, which severely limits how it can be joined or integrated into larger assemblies. This often leads to more complex designs that rely solely on mechanical fits.

Longer Lead Times for Custom Parts

The combination of higher material cost and manufacturing difficulty means that obtaining custom-designed PTFE bushes often involves longer lead times and higher tooling costs compared to more conventional materials.

When to Avoid PTFE Bushes

Based on these limitations, consider alternative materials if your application fits any of the following profiles.

- If your primary focus is high load capacity: Choose a harder material like bronze, a filled polymer, or a bearing-grade metal, as pure PTFE will deform and creep under pressure.

- If your application is in a dirty or abrasive environment: Avoid PTFE, as embedded particles can quickly score and destroy expensive mating surfaces like shafts and stanchions.

- If you require tight, stable dimensional tolerances under load: PTFE's tendency to cold flow makes it unsuitable for maintaining precise dimensions under constant pressure.

- If cost is the primary driver for a simple application: Consider more economical and easily manufactured materials, as PTFE carries a significant cost premium.

Understanding these limitations is the key to leveraging PTFE's unique benefits without risking application failure.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Mechanical Weakness & Creep | Poor dimensional stability under sustained load; deforms over time. |

| High Sensitivity to Abrasion | Rapid wear in dirty environments; embedded particles can damage mating surfaces. |

| Higher Cost | More expensive than traditional materials like bronze or other polymers. |

| Manufacturing Challenges | Difficult to machine; cannot be cemented or welded; longer lead times for custom parts. |

| Thermal & Chemical Limits | Melts at 326°C (620°F); vulnerable to specific fluorinating agents and radiation. |

Need a High-Performance PTFE Solution That Overcomes These Limitations?

PTFE's disadvantages in strength and wear can be critical for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. At KINTEK, we don't just supply standard PTFE components—we engineer solutions.

We specialize in precision manufacturing and custom fabrication of PTFE seals, liners, labware, and more. By understanding your specific operational environment and performance requirements, we can help you select the right material or a custom-designed component that delivers the benefits of PTFE without the drawbacks.

Let us help you achieve:

- Enhanced Durability: Custom formulations and designs to improve load capacity and resistance to creep and abrasion.

- Precision and Reliability: Components manufactured to exact tolerances for critical applications.

- Faster Time-to-Market: From prototypes to high-volume orders, we streamline the process to meet your timeline.

Don't let material limitations compromise your application. Contact our experts today for a consultation on your specific needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications