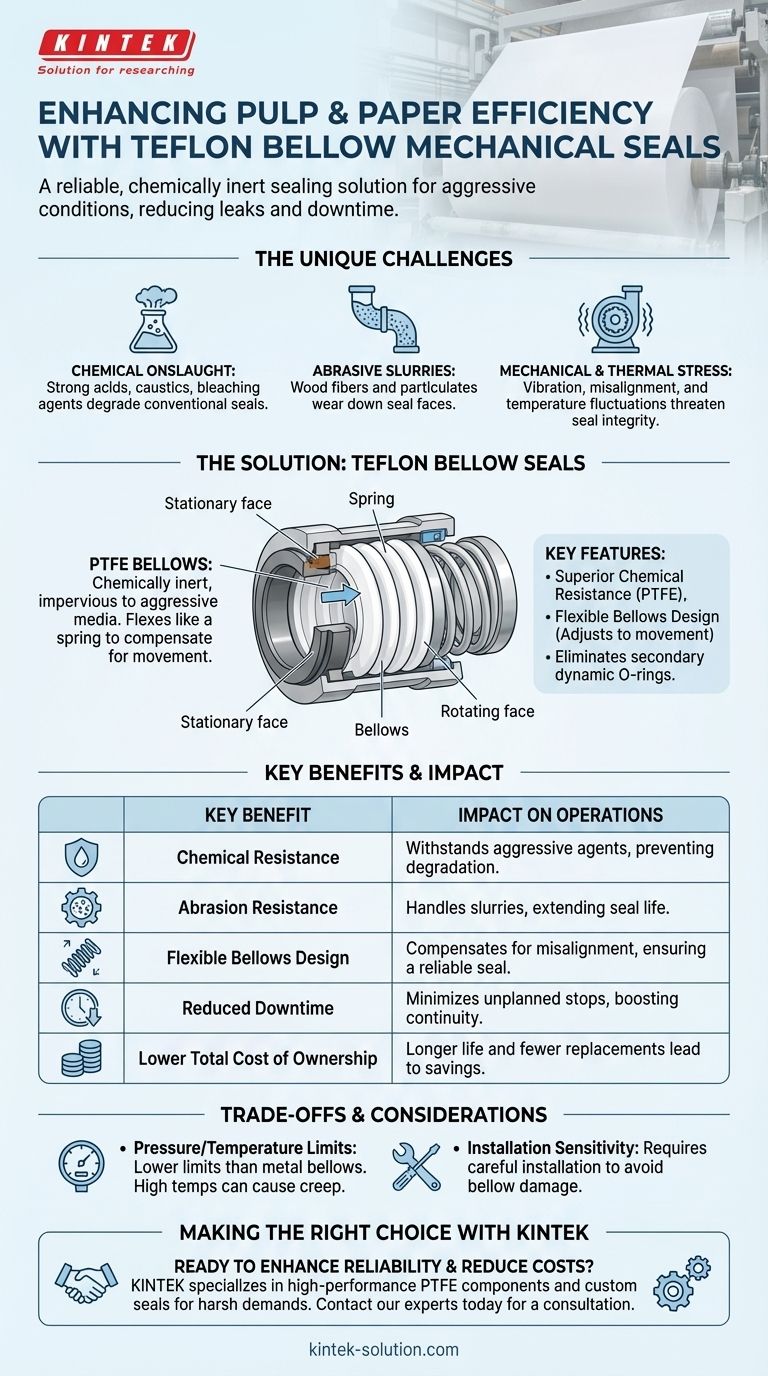

In the pulp and paper industry, Teflon bellow mechanical seals enhance equipment efficiency by providing a highly reliable and chemically inert sealing solution. This design directly combats the aggressive and abrasive conditions common in pulp processing, drastically reducing leaks, minimizing unplanned downtime, and lowering long-term maintenance costs.

The core value of a Teflon bellow seal is not merely stopping a leak; it is about ensuring process integrity and operational continuity in an industry where constant chemical attack and mechanical stress threaten productivity.

The Unique Sealing Challenges in Pulp and Paper

To understand the effectiveness of these seals, we must first appreciate the uniquely hostile environment of a pulp and paper mill. Sealing rotating equipment here is a significant engineering challenge.

The Chemical Onslaught

Pulping and bleaching processes rely on a cocktail of aggressive chemicals. This includes strong acids, caustic sodas, and powerful bleaching agents that can quickly degrade conventional sealing materials like elastomers.

Abrasive Slurries

Pulp slurry itself is highly abrasive. It contains wood fibers, fillers, and other particulates that can rapidly wear down the faces of a mechanical seal, leading to premature failure.

Mechanical and Thermal Stress

Pumps, agitators, and rollers in a paper mill are subject to significant vibration, potential shaft misalignment, and fluctuating temperatures. A seal must be able to compensate for this movement to maintain a consistent seal.

How Teflon Bellow Seals Solve the Problem

The design of a Teflon bellow mechanical seal directly addresses these specific challenges through two key features: its material and its construction.

The Power of PTFE (Teflon)

The bellows component is manufactured from Polytetrafluoroethylene (PTFE), commonly known as Teflon. This material is nearly chemically inert, making it impervious to the vast majority of chemicals used in the pulp and paper industry.

This superior chemical resistance ensures the seal’s core component does not swell, harden, or degrade over time, providing a significantly longer service life than other materials.

The Flexibility of the Bellows Design

The convoluted "bellows" shape acts like a spring. This design allows the seal to flex and automatically adjust to shaft vibration, radial movement, and minor misalignment.

By maintaining constant, uniform pressure on the seal faces, the bellow ensures a reliable seal even under dynamic operating conditions where rigid seals would fail. This design also eliminates the need for a secondary dynamic O-ring, removing a common point of failure found in other seal types.

Enhancing Environmental and Operational Safety

By creating a durable and reliable seal, these components are critical for environmental compliance. They effectively prevent the leakage of harsh chemicals and contaminated water into the environment.

This directly helps facilities meet stringent regulatory requirements and avoids the financial and reputational costs associated with environmental incidents.

Understanding the Trade-offs

While highly effective, Teflon bellow seals are not a universal solution. Understanding their limitations is key to proper application.

Pressure and Temperature Boundaries

Standard PTFE bellows can have lower pressure limits compared to metal bellow or non-bellow "pusher" seal designs. High temperatures can also cause PTFE to "creep" or deform under load, which must be accounted for in the application engineering.

Installation Sensitivity

The integrity of the bellow is critical to the seal's function. The bellow can be damaged if not installed with care, which can lead to premature failure. Proper training and adherence to installation procedures are essential.

Making the Right Choice for Your Application

Selecting the correct seal is a strategic decision that balances performance, cost, and operational goals.

- If your primary focus is reliability in aggressive chemical media: Teflon bellow seals are an exceptional choice due to PTFE's unmatched chemical resistance.

- If you are dealing with significant shaft misalignment or slurry: The flexible bellow design provides a more forgiving and durable seal than rigid alternatives.

- If your application involves very high pressures or temperatures: You may need to evaluate carbon-filled PTFE grades or alternative seal designs, such as metal bellows, to ensure long-term performance.

- If your goal is to reduce maintenance costs and downtime: The extended lifespan of these seals in their target applications often provides a lower total cost of ownership.

Ultimately, investing in the correct sealing technology is a direct investment in your plant's reliability and profitability.

Summary Table:

| Key Benefit | Impact on Pulp & Paper Operations |

|---|---|

| Chemical Resistance | Withstands acids, caustics, and bleaching agents, preventing seal degradation. |

| Abrasion Resistance | Handles abrasive pulp slurries, extending seal life and reducing wear. |

| Flexible Bellows Design | Compensates for shaft misalignment and vibration, ensuring a reliable seal. |

| Reduced Downtime | Minimizes unplanned maintenance stops, boosting operational continuity. |

| Lower Total Cost of Ownership | Longer service life and fewer replacements lead to significant cost savings. |

Ready to enhance your equipment's reliability and reduce operational costs?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom mechanical seals designed for the harsh demands of the pulp and paper, semiconductor, medical, and industrial sectors. Our precision engineering ensures your seals deliver maximum chemical resistance and durability.

We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your specific application.

Contact our experts today for a consultation and see how our PTFE sealing solutions can protect your productivity and your bottom line.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What is the pressure resistance capability of PTFE oil seals compared to conventional oil seals? Discover the High-Performance Advantage

- What industries benefit from using PTFE gaskets in ball valves? Ensure Purity & Reliability in Critical Processes

- What are the key differences between PTFE and EPDM valve seats? Choose the Right Material for Your Application

- What materials are used to manufacture PTFE bars? A Guide to Virgin & Filled PTFE

- What are the high temperature capabilities of PTFE seals? Maximize Performance Up to 600°F (316°C)

- Why is PTFE considered an ideal material for demanding hydraulic and pneumatic applications? Ensure Superior Sealing Performance and Reliability

- What are the primary advantages of PTFE bellows? Achieve Unmatched Chemical & Thermal Resilience

- Is Teflon always necessary for heat transfer applications? Weighing Protection vs. Precision