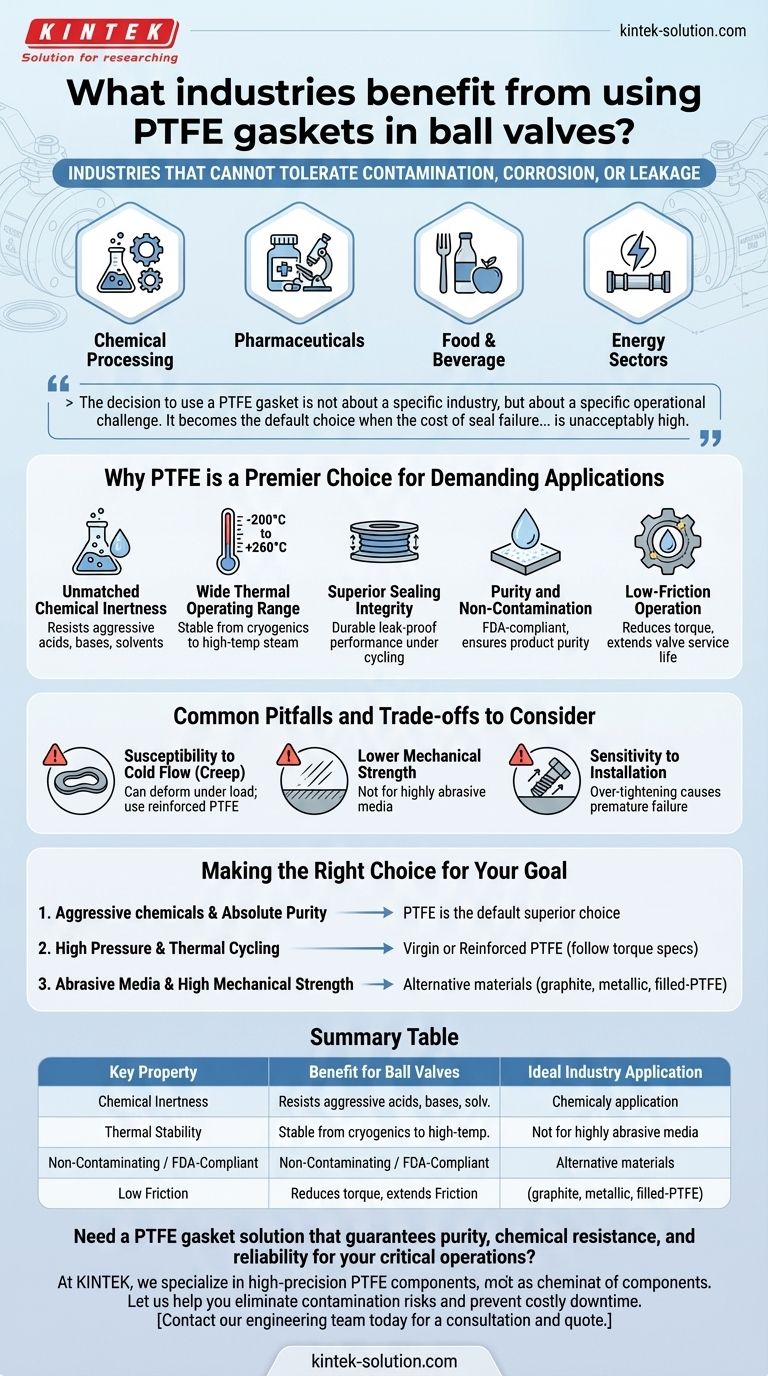

In short, industries that cannot tolerate contamination, corrosion, or leakage benefit most from using PTFE gaskets in ball valves. This includes chemical processing, pharmaceuticals, food and beverage, and high-pressure energy sectors, where PTFE's unique combination of chemical inertness and temperature resilience is indispensable for safe and reliable operations.

The decision to use a PTFE gasket is not about a specific industry, but about a specific operational challenge. It becomes the default choice when the cost of seal failure—whether through contamination, chemical attack, or leakage—is unacceptably high.

Why PTFE is a Premier Choice for Demanding Applications

The value of Polytetrafluoroethylene (PTFE) in a ball valve gasket comes from a distinct set of properties that solve critical engineering problems in sensitive and aggressive environments.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, including aggressive acids, bases, and solvents. This makes it essential in chemical processing, where gaskets are constantly exposed to corrosive media that would degrade lesser materials.

Wide Thermal Operating Range

PTFE maintains its integrity and sealing capability across an exceptionally broad temperature spectrum, typically from -200°C to +260°C (-328°F to +500°F). This stability is critical for processes involving cryogenic fluids or high-temperature steam and chemicals.

Superior Sealing Integrity

These gaskets provide a durable and reliable seal under repeated compression cycles. For applications in the energy sector or other high-pressure systems, this leak-proof performance is non-negotiable for safety and efficiency.

Purity and Non-Contamination

PTFE is a non-contaminating material and is often FDA-compliant, making it a mandatory choice for industries where product purity is paramount. Its non-stick surface also facilitates easy cleaning and prevents residue buildup in pharmaceutical and food processing lines.

Low-Friction Operation

The material has an extremely low coefficient of friction, acting as a self-lubricating surface. In a ball valve, this reduces the torque required to operate the valve, minimizing wear on moving parts and extending the valve's service life.

Common Pitfalls and Trade-offs to Consider

While PTFE is a superior material, it is not universally perfect. Understanding its limitations is key to successful implementation and avoiding premature failure.

Susceptibility to Cold Flow (Creep)

PTFE can deform or "creep" over time under a constant load, especially at elevated temperatures. This can lead to a loss of bolt torque and potentially compromise the seal. Proper installation and using reinforced PTFE grades can mitigate this risk.

Lower Mechanical Strength

Compared to metallic gaskets, PTFE is a much softer material. It is not suitable for applications with highly abrasive media or slurries, which can physically damage the gasket surface and cause leaks.

Sensitivity to Installation

The effectiveness of a PTFE gasket is highly dependent on correct installation. Over-tightening the bolts is a common mistake that can crush the gasket, causing excessive cold flow and leading to premature failure.

Making the Right Choice for Your Goal

Selecting the correct gasket material requires matching its properties to your primary operational demand.

- If your primary focus is handling aggressive chemicals or ensuring absolute purity: PTFE is the default, superior choice due to its extreme chemical resistance and non-contaminating properties.

- If your application involves high pressure combined with thermal cycling: Virgin or reinforced PTFE provides a reliable seal, but you must account for potential cold flow by following precise torque specifications.

- If your system contains abrasive media or requires very high mechanical strength: You should consider alternative materials like graphite or metallic gaskets, or specific filled-PTFE compounds designed for such service.

Ultimately, understanding these core material properties empowers you to select a gasket that guarantees both operational safety and process efficiency.

Summary Table:

| Key Property | Benefit for Ball Valves | Ideal Industry Application |

|---|---|---|

| Chemical Inertness | Resists aggressive acids, bases, solvents | Chemical Processing, Pharmaceuticals |

| Thermal Stability (-200°C to +260°C) | Reliable seal from cryogenics to high-temp steam | Energy, Cryogenics, High-Temp Processing |

| Non-Contaminating / FDA-Compliant | Ensures product purity, easy to clean | Food & Beverage, Pharmaceuticals, Biotechnology |

| Low Friction / Self-Lubricating | Reduces operating torque, extends valve life | All industries for longer service life and reduced maintenance |

Need a PTFE gasket solution that guarantees purity, chemical resistance, and reliability for your critical operations?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, gaskets, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require a prototype for testing or a high-volume production run, our expertise in custom fabrication ensures you get a sealing solution perfectly matched to your specific operational demands, material compatibility, and performance requirements.

Let us help you eliminate contamination risks and prevent costly downtime. Contact our engineering team today for a consultation and quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the difference between PTFE sheets and Teflon paper? A Guide to Choosing the Right Form

- What are the advantages of using PTFE rotary seals over rubber elastomer seals? Superior Performance in Extreme Conditions

- What makes extruded PTFE rods chemically resistant? Unmatched Stability from its Molecular Structure

- How do Teflon bearings perform in demanding applications? Superior Performance in Harsh Environments

- What makes ePTFE gaskets effective against gas leakage? The Key to Superior Gas Sealing

- Why is PTFE's low friction property beneficial in manufacturing? To Reduce Wear, Downtime & Energy Costs

- What happens during suspension polymerization for PTFE production? Creating High-Purity Granular Polymer

- What do the ratings A, B, and C indicate in the chemical resistance table for Filled PTFE? A Guide to Material Safety