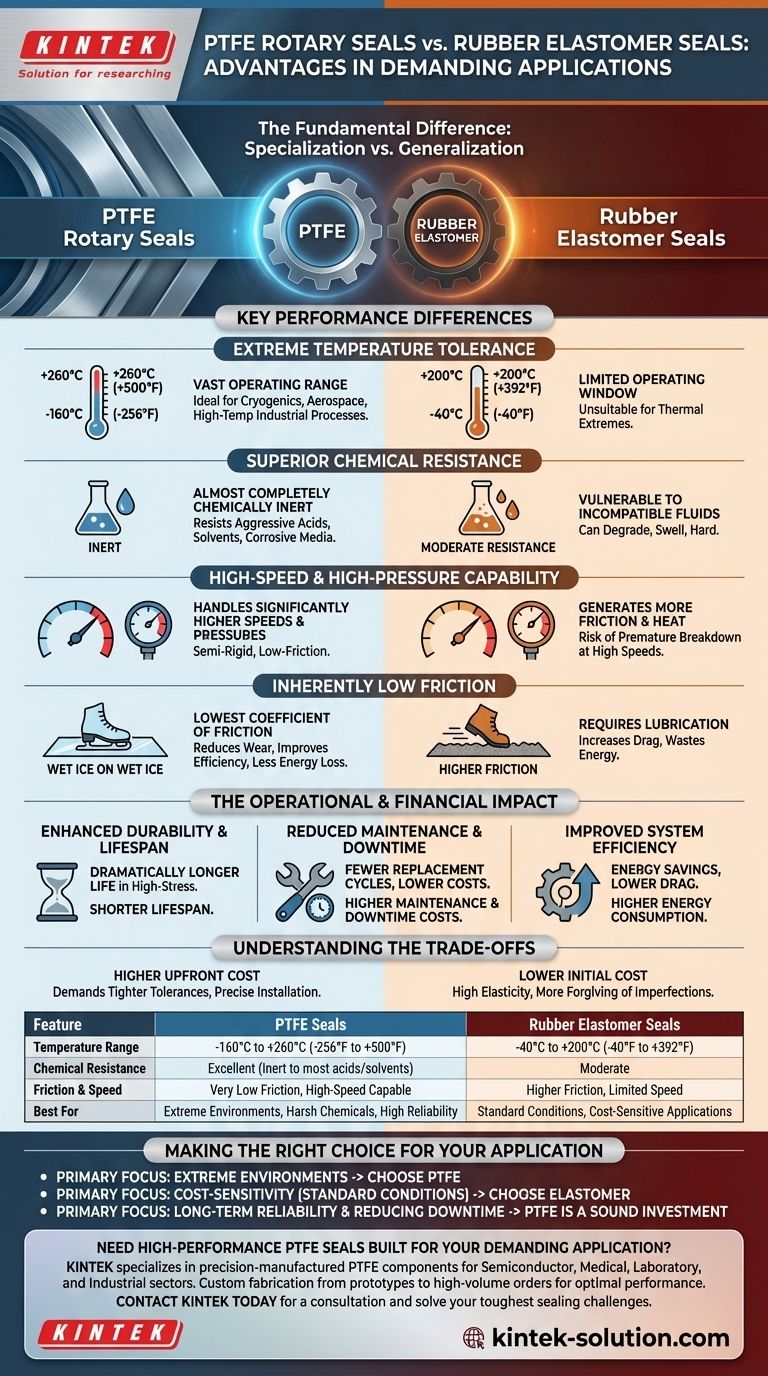

In short, PTFE rotary seals excel over rubber elastomer seals in demanding applications. They are engineered to withstand higher speeds, wider temperature ranges, greater pressures, and more aggressive chemicals where traditional rubber seals would quickly degrade and fail.

The fundamental difference is one of specialization versus generalization. Rubber elastomer seals are a reliable, cost-effective choice for standard operating conditions, while PTFE seals are a high-performance solution engineered specifically for the most extreme industrial environments.

Key Performance Differences: PTFE vs. Elastomer

To understand why you would choose one over the other, it's essential to compare their core material properties and how those translate to real-world performance.

Extreme Temperature Tolerance

PTFE seals operate effectively within a vast temperature range, typically from –160°C to +260°C (–256°F to +500°F).

This makes them the default choice for applications involving cryogenic liquids or high-temperature industrial processes found in aerospace, automotive, and heavy machinery.

In contrast, most rubber elastomer seals have a much narrower operating window, generally between –40°C and +200°C (–40°F to +392°F), making them unsuitable for thermal extremes.

Superior Chemical Resistance

PTFE is almost completely chemically inert. It can withstand exposure to aggressive acids, solvents, and other corrosive media without swelling, hardening, or degrading.

This property is critical in industries like pharmaceutical manufacturing, chemical processing, and semiconductor fabrication, where seal integrity is non-negotiable.

Rubber seals offer only moderate chemical resistance and can be quickly compromised by incompatible fluids, leading to leaks and system failure.

High-Speed and High-Pressure Capability

The semi-rigid nature and low-friction surface of PTFE allow it to handle significantly higher rotational speeds and system pressures than elastomers.

Rubber seals generate more friction, which creates heat. At high speeds, this heat buildup can cause the rubber to break down, leading to premature seal failure. PTFE's properties mitigate this risk entirely.

Inherently Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This means it requires less energy to rotate a shaft.

This natural lubricity reduces wear and tear on both the seal and the shaft, improves overall system efficiency by minimizing energy loss, and can often perform in applications with little to no lubrication.

The Operational and Financial Impact

These technical advantages result in tangible benefits related to cost, maintenance, and overall system reliability.

Enhanced Durability and Lifespan

In high-stress applications, PTFE seals dramatically outlast their elastomer counterparts. Their resistance to heat, chemicals, and wear means they maintain their integrity for much longer.

Reduced Maintenance and Downtime

A longer service life directly translates to fewer replacement cycles, lower maintenance costs, and most importantly, less operational downtime.

For critical equipment in oil and gas or manufacturing, the cost of downtime often far exceeds the cost of the component, making PTFE a sound investment.

Improved System Efficiency

By reducing frictional drag, PTFE seals contribute to more efficient machinery. Less energy is wasted overcoming resistance, which can lead to measurable energy savings over the equipment's lifetime.

Understanding the Trade-offs

While PTFE offers clear advantages in demanding scenarios, it is not the universal solution. An objective assessment requires acknowledging where elastomers still hold value.

Material Cost and Elasticity

PTFE seals typically have a higher upfront cost than standard rubber seals. For applications with mild conditions, the performance benefits may not justify the added expense.

Furthermore, rubber's high elasticity makes it more forgiving of minor shaft imperfections, surface finishes, or installation misalignments. The more rigid nature of PTFE demands tighter tolerances and more precise installation.

Application Simplicity

For simple, low-speed, and low-temperature static or dynamic applications, a standard elastomer seal is often the most practical and economical choice. It provides a reliable seal without the need for the specialized properties of PTFE.

Making the Right Choice for Your Application

Your decision should be driven entirely by the operational demands of your equipment.

- If your primary focus is extreme environments: Choose PTFE for its unmatched resistance to high temperatures, aggressive chemicals, high speeds, and pressures.

- If your primary focus is cost-sensitivity under standard conditions: An elastomer seal is the more economical and entirely suitable choice for moderate temperatures, speeds, and common lubricants.

- If your primary focus is long-term reliability and reducing downtime: The higher initial cost of a PTFE seal is frequently justified by its significantly longer lifespan in any demanding application.

Ultimately, selecting the right seal is not about which material is "better," but about precisely matching the material's capabilities to your operational demands.

Summary Table:

| Feature | PTFE Seals | Rubber Elastomer Seals |

|---|---|---|

| Temperature Range | -160°C to +260°C (-256°F to +500°F) | -40°C to +200°C (-40°F to +392°F) |

| Chemical Resistance | Excellent (Inert to most acids/solvents) | Moderate |

| Friction & Speed | Very Low Friction, High-Speed Capable | Higher Friction, Limited Speed |

| Best For | Extreme Environments, Harsh Chemicals, High Reliability | Standard Conditions, Cost-Sensitive Applications |

Need high-performance PTFE seals built for your demanding application?

At KINTEK, we specialize in precision-manufactured PTFE components, including custom rotary seals, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a seal that delivers maximum durability, reduces downtime, and withstands the most extreme conditions.

We provide custom fabrication from prototypes to high-volume orders, ensuring a perfect fit and optimal performance for your specific needs.

Contact KINTEK today for a consultation and let our experts help you solve your toughest sealing challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- How do PTFE and NBR oil seals compare in terms of dry running capability? The Ultimate Guide for Reliability

- Can PTFE rods be machined into complex shapes? Yes, with precision engineering for custom parts.

- What temperature range can PTFE rotary shaft seals withstand? Operate from -200°C to +260°C

- What are Teflon encapsulated O-Rings and what materials are they crafted with? Superior Seals for Harsh Environments

- What are some common applications of filled PTFE? Enhance Performance in Demanding Industries

- How does the non-stick surface of PTFE flange gaskets benefit installation and maintenance? Cut Costs & Downtime

- What is the purpose of using Teflon sheets with a heat press machine? Protect Your Press & Improve Print Quality

- What makes PTFE compensators suitable for handling aggressive chemicals? Unmatched Chemical Inertness for Your System