In manufacturing, PTFE's low friction is highly beneficial because it dramatically reduces wear and tear on moving parts, minimizes energy loss, and extends the operational life of machinery. This unique property allows components to slide against each other with minimal resistance, directly translating to lower maintenance costs and more reliable equipment.

Friction is a fundamental driver of mechanical failure, energy waste, and operational cost in any manufacturing environment. PTFE's exceptionally low coefficient of friction directly mitigates these issues, making it a critical material for creating more durable, efficient, and reliable systems.

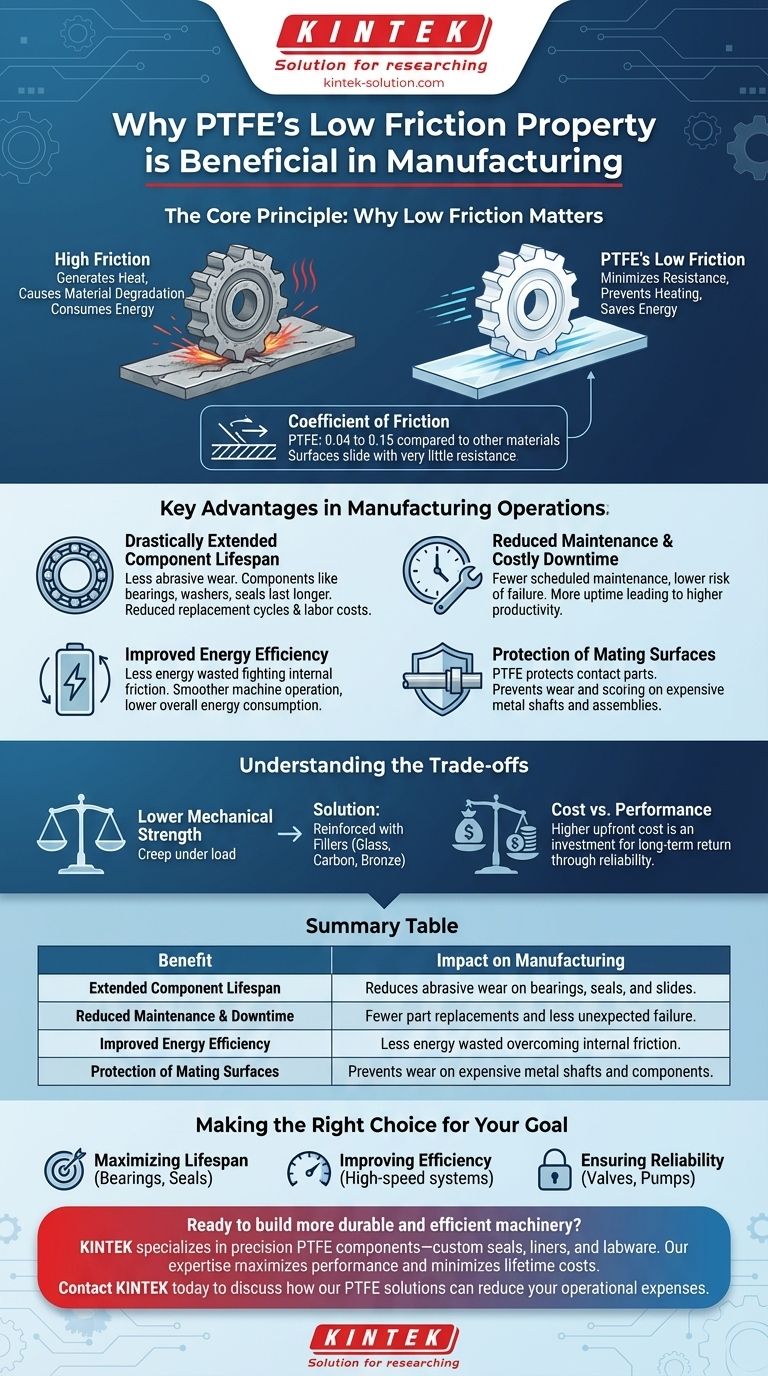

The Core Principle: Why Low Friction Matters

In any system with moving parts, friction is the primary force that must be overcome. It generates heat, causes material degradation, and consumes energy. PTFE's unique molecular structure gives it one of the lowest coefficients of friction of any solid material, fundamentally changing this dynamic.

Understanding the Coefficient of Friction

The coefficient of friction is a value that represents the ratio of the force of friction between two bodies and the force pressing them together.

PTFE's coefficient is exceptionally low, typically ranging from 0.04 to 0.15. This means surfaces made of or coated with PTFE slide against each other with very little resistance.

How This Benefits Mechanical Systems

In applications like bearings, gears, seals, and slides, minimizing resistance is critical. By introducing PTFE, you are engineering a system where less energy is wasted on friction and more is available for productive work.

This also prevents frictional heating, which can cause parts to expand, deform, or degrade, especially in high-speed or high-pressure applications.

Key Advantages in Manufacturing Operations

The physical principle of low friction translates into several significant, tangible business benefits that reduce costs and improve productivity.

Drastically Extended Component Lifespan

Less friction means less abrasive wear. Components like bearings, washers, and seals made from PTFE simply last longer because they aren't grinding themselves down during operation.

This directly reduces the need for frequent part replacements, saving money on both the components and the labor required to install them.

Reduced Maintenance and Costly Downtime

Longer-lasting parts mean fewer scheduled maintenance intervals and a lower risk of unexpected mechanical failure.

For a manufacturing line, this is a critical advantage. Less downtime means more uptime, leading to higher productivity and output.

Improved Energy Efficiency

Machinery with PTFE components wastes less energy fighting its own internal friction. While the savings on a single bearing may be small, they become significant when scaled across an entire factory.

This results in smoother, more efficient machine operation and can contribute to lower overall energy consumption.

Protection of Mating Surfaces

A crucial and often overlooked benefit is that PTFE protects the parts it comes into contact with.

A low-friction PTFE oil seal, for example, not only resists wear itself but also prevents wear and scoring on the expensive metal shaft it is sealing. This protects the integrity of the entire assembly.

Understanding the Trade-offs

While its low friction is a powerful advantage, PTFE is not a universal solution. It's essential to understand its limitations to apply it effectively.

Lower Mechanical Strength

Compared to metals, pure PTFE is a relatively soft material. It can be susceptible to "creep" or deformation under heavy, constant loads.

To counteract this, PTFE is often reinforced with fillers like glass, carbon, or bronze to enhance its strength and durability for more demanding structural roles.

Cost vs. Performance

PTFE components are often more expensive upfront than those made from traditional materials like nylon or certain metals.

The decision to use PTFE is an investment. You are trading a higher initial material cost for a long-term return through reduced maintenance, lower replacement frequency, and improved reliability.

Making the Right Choice for Your Goal

When deciding where to apply PTFE, your primary objective will guide your selection.

- If your primary focus is maximizing equipment lifespan: Use PTFE for critical wear components like bearings, bushings, and seals to dramatically reduce replacement cycles and labor costs.

- If your primary focus is improving operational efficiency: Apply PTFE coatings or components in high-speed or continuous-motion systems to minimize energy loss and heat generation from friction.

- If your primary focus is ensuring system reliability: Incorporate PTFE in critical applications where failure is costly, such as valves and pumps, to prevent seizure and wear-related breakdowns.

Ultimately, leveraging PTFE's low friction is a strategic engineering decision to build more robust, efficient, and dependable machinery.

Summary Table:

| Benefit | Impact on Manufacturing |

|---|---|

| Extended Component Lifespan | Reduces abrasive wear on bearings, seals, and slides. |

| Reduced Maintenance & Downtime | Fewer part replacements and less unexpected failure. |

| Improved Energy Efficiency | Less energy wasted overcoming internal friction. |

| Protection of Mating Surfaces | Prevents wear on expensive metal shafts and components. |

Ready to build more durable and efficient machinery?

KINTEK specializes in precision PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get components that maximize performance and minimize lifetime costs.

Contact KINTEK today to discuss how our PTFE solutions can reduce your operational expenses.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- In which industries are PTFE expansion joints commonly used? Critical for Chemical, Power, and Hygienic Systems

- What are the two main methods for producing PTFE? Choose the Right Path for Your Application

- What are the key considerations for successful PTFE machining? Master Precision for Soft Materials

- How should PTFE gaskets be stored to maintain their quality? Ensure Long-Term Sealing Reliability

- What role does the PTFE sheet play in design transfer? Achieve Flawless, Professional Results

- What capabilities exist for manufacturing PTFE with different methods? A Guide to Polymerization and Fabrication

- How does PTFE perform in cryogenic applications? Maintain Performance in Extreme Cold

- When is machining preferred for PTFE part fabrication? For High-Precision, Complex, or Low-Volume Needs