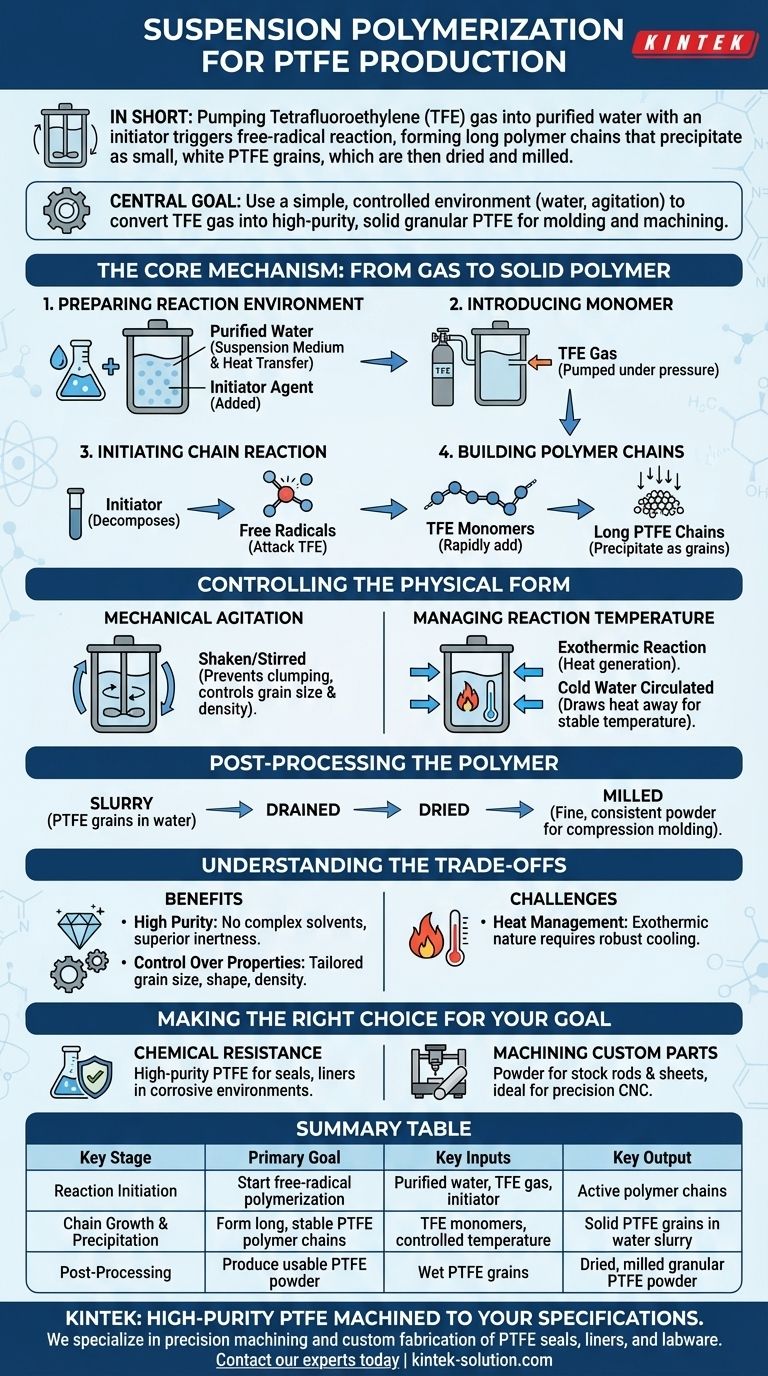

In short, suspension polymerization for PTFE involves pumping tetrafluoroethylene (TFE) gas into a chamber of purified water containing an initiator. The initiator triggers a free-radical reaction, causing the TFE monomers to link into long polymer chains. These chains precipitate as small, white grains of PTFE, which are then dried and milled into a fine powder.

The central goal of suspension polymerization is to use a simple, controlled environment—purified water and mechanical agitation—to convert TFE gas into high-purity, solid granular PTFE with specific physical properties ideal for molding and machining.

The Core Mechanism: From Gas to Solid Polymer

The transformation of a gas into one of the most stable polymers known is a carefully controlled chemical process. Each step is designed to manage the reaction and define the final material's characteristics.

Preparing the Reaction Environment

The process begins by filling a reaction chamber with purified water. The water does not react with the TFE but acts as a suspension medium and an excellent heat transfer agent, which is critical for controlling the reaction temperature. An initiator agent is then added to the water to kick-start the polymerization.

Introducing the Monomer

Tetrafluoroethylene (TFE), a gas at room temperature, is pumped under pressure into the sealed chamber. The mechanical agitation, or shaking, of the chamber helps disperse the TFE within the water.

Initiating the Chain Reaction

The initiator decomposes to form free radicals. These highly reactive molecules attack the TFE monomers, breaking their double bonds and starting a chain reaction. This is the fundamental principle of free radical polymerization.

Building the Polymer Chains

Once initiated, TFE monomers rapidly add to the growing chain, one after another. This process forms extremely long and stable polymer chains of Polytetrafluoroethylene (PTFE). Because PTFE is insoluble in water, it precipitates out of the solution as it forms.

Controlling the Physical Form

Creating the correct chemical polymer is only half the battle. The physical process must be managed precisely to produce a usable material.

The Role of Mechanical Agitation

The reaction chamber is mechanically shaken or stirred throughout the process. This agitation prevents the newly formed PTFE particles from clumping together into unmanageable masses. It ensures they remain suspended as distinct grains and helps control their final size and density.

Managing Reaction Temperature

Polymerization is an exothermic reaction, meaning it generates a significant amount of heat. Cold water is circulated around the reaction chamber to draw this heat away. Maintaining a stable temperature is crucial for controlling the rate of reaction and ensuring the final polymer has the desired molecular weight and properties.

Post-Processing the Polymer

After the reaction is complete, the chamber contains a slurry of solid PTFE grains in water. This mixture is drained, and the PTFE is thoroughly dried. The dried grains are then milled into a fine powder with a consistent particle size, making it suitable for downstream processing like compression molding.

Understanding the Trade-offs

Suspension polymerization is a widely used and effective method, but it's essential to understand its inherent characteristics.

Benefit: High Purity

Because the reaction occurs in purified water without complex solvents, the resulting PTFE is exceptionally pure. This high purity is a key reason for PTFE's outstanding chemical inertness.

Benefit: Control Over Particle Properties

The combination of agitation speed, temperature, and pressure gives manufacturers significant control over the final grain size, shape, and density of the PTFE powder. This allows the material to be tailored for specific molding applications.

Challenge: Heat Management

The exothermic nature of the reaction demands a robust and precise cooling system. Any failure in temperature control can lead to a runaway reaction and produce a polymer with inconsistent or poor properties.

Making the Right Choice for Your Goal

The granular powder produced by this method is the starting point for creating solid PTFE stock shapes used in countless applications.

- If your primary focus is chemical resistance: The high-purity PTFE from this process offers the superior inertness required for seals, liners, and components in corrosive environments.

- If your primary focus is machining custom parts: The resulting powder is ideal for compression molding into stock rods and sheets, which have the resilience and consistency needed for precision CNC machining.

Ultimately, suspension polymerization is a foundational process that reliably creates a clean, stable, and highly versatile fluoropolymer.

Summary Table:

| Key Stage | Primary Goal | Key Inputs | Key Output |

|---|---|---|---|

| Reaction Initiation | Start free-radical polymerization | Purified water, TFE gas, initiator | Active polymer chains |

| Chain Growth & Precipitation | Form long, stable PTFE polymer chains | TFE monomers, controlled temperature | Solid PTFE grains in water slurry |

| Post-Processing | Produce usable PTFE powder | Wet PTFE grains | Dried, milled granular PTFE powder |

Need high-purity PTFE components machined to your exact specifications?

The suspension polymerization process described is the foundation for creating the premium PTFE stock shapes we use. At KINTEK, we specialize in precision machining and custom fabrication of PTFE seals, liners, and labware from this high-quality material for the semiconductor, medical, and industrial sectors. From prototypes to high-volume orders, we ensure the chemical resistance and performance your application demands.

Contact our experts today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs