In demanding applications, Teflon bearings consistently outperform many traditional materials. Their superior performance stems directly from a unique combination of an extremely low coefficient of friction, high wear resistance, and the ability to operate reliably in harsh chemical and temperature environments where metals or other plastics would fail.

The core decision is not about whether Teflon is "better," but about identifying the specific engineering problem you need to solve. Teflon excels where self-lubrication, chemical inertness, and smooth motion are critical, while traditional metal bearings remain superior for applications defined by extremely high loads and rigidity.

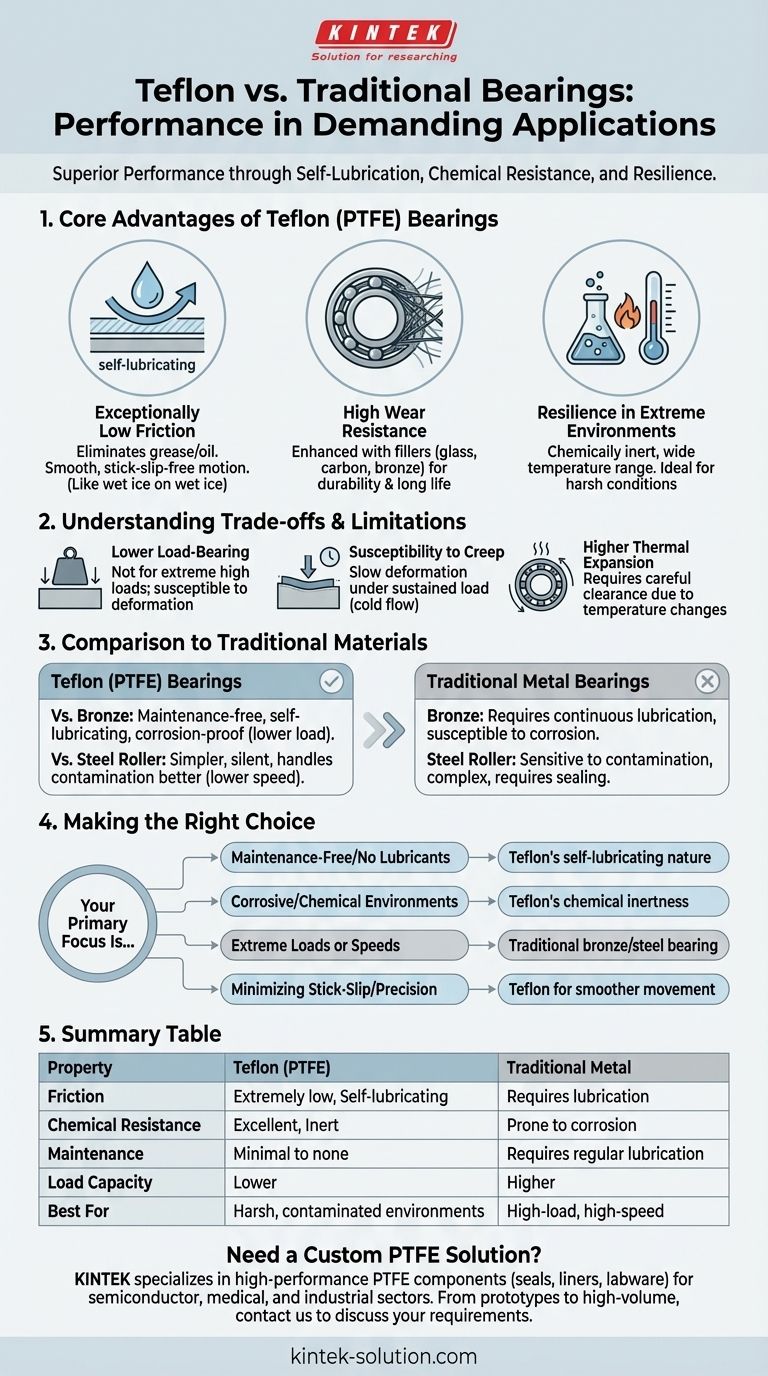

The Core Advantages of Teflon (PTFE) Bearings

The value of Teflon—more accurately, Polytetrafluoroethylene (PTFE)—in bearing applications comes from a set of inherent material properties. These are often enhanced by blending the PTFE with fillers to create a composite material tailored for specific demands.

Exceptionally Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, comparable to wet ice on wet ice. This results in a self-lubricating surface that eliminates the need for external grease or oil.

This property is critical for applications where maintenance is difficult, contamination from lubricants is unacceptable (e.g., food processing), or smooth, stick-slip-free motion is required.

High Wear Resistance

While pure PTFE is relatively soft, commercial Teflon bearings are typically composites. They are blended with fillers like glass fiber, carbon, graphite, or bronze.

These fillers dramatically improve wear resistance, compressive strength, and thermal conductivity without sacrificing the low-friction nature of the base material. This ensures durability and a long service life.

Resilience in Extreme Environments

Teflon is almost completely chemically inert, meaning it will not react with or degrade from exposure to most acids, bases, and solvents. This makes it an ideal choice for chemical processing pumps and valves.

It also operates effectively across a wide temperature range, maintaining its properties in conditions that would cause other plastics to become brittle or melt.

Understanding the Trade-offs and Limitations

No material is perfect for every situation. Acknowledging the limitations of PTFE is essential for proper engineering design and avoiding misapplication.

Lower Load-Bearing Capacity

Compared to metal bearings like steel or bronze, PTFE composites have a lower compressive strength. They are not suitable for applications with extremely high static or dynamic loads.

Exceeding the material's load limit can lead to permanent deformation and premature failure.

Susceptibility to Creep (Cold Flow)

Under a sustained load, especially at elevated temperatures, PTFE can slowly deform over time. This phenomenon, known as creep or cold flow, must be factored into the design.

Engineers must account for this by ensuring the load and temperature parameters remain well within the material's specified limits to maintain dimensional stability.

Higher Thermal Expansion

PTFE has a significantly higher coefficient of thermal expansion than metals. This means it expands and contracts more with temperature changes.

Designers must incorporate appropriate clearances and tolerances to prevent the bearing from seizing or becoming too loose as operating temperatures fluctuate.

How Teflon Compares to Specific Traditional Materials

Choosing the right bearing requires comparing it directly against the alternatives for your specific use case.

Versus Bronze Bearings

Bronze is a classic bearing material known for its durability and load capacity. However, it requires continuous lubrication to function properly and is susceptible to corrosion.

Teflon bearings offer a maintenance-free, self-lubricating, and corrosion-proof alternative, though for a lower maximum load.

Versus Steel Roller Bearings

Steel bearings are designed for very high loads and high rotational speeds. They are precise but complex, consisting of multiple moving parts. They are also sensitive to contamination and require careful sealing and lubrication.

Teflon plain bearings are simpler, silent, and handle contaminated environments far better. They are superior for lower-speed, oscillating, or sliding motions where steel bearings would be excessive and prone to failure from lack of lubrication.

Making the Right Choice for Your Application

Your final decision should be driven by the single most critical demand of your application.

- If your primary focus is maintenance-free operation or eliminating lubricants: Teflon's self-lubricating nature is its defining and unparalleled advantage.

- If your primary focus is performance in corrosive or chemical environments: Teflon's chemical inertness is superior to almost any metal bearing.

- If your primary focus is handling extremely high static loads or speeds: A traditional bronze or steel roller bearing is the more robust and reliable choice.

- If your primary focus is minimizing stick-slip motion for precise positioning: Teflon provides smoother, more consistent movement than lubricated metal bearings.

Ultimately, selecting the correct bearing material is about aligning its inherent strengths with the unique challenges of your engineering goal.

Summary Table:

| Property | Teflon (PTFE) Bearings | Traditional Metal Bearings |

|---|---|---|

| Friction | Extremely low, self-lubricating | Requires external lubrication |

| Chemical Resistance | Excellent, inert to most chemicals | Prone to corrosion |

| Maintenance | Minimal to none | Requires regular lubrication |

| Load Capacity | Lower | Higher |

| Best For | Harsh, corrosive, or contaminant-sensitive environments | High-load, high-speed applications |

Need a custom PTFE bearing solution for your demanding application? KINTEK specializes in manufacturing high-performance PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication—from prototypes to high-volume orders—ensure you get a bearing that excels in self-lubrication, chemical resistance, and durability. Contact us today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application