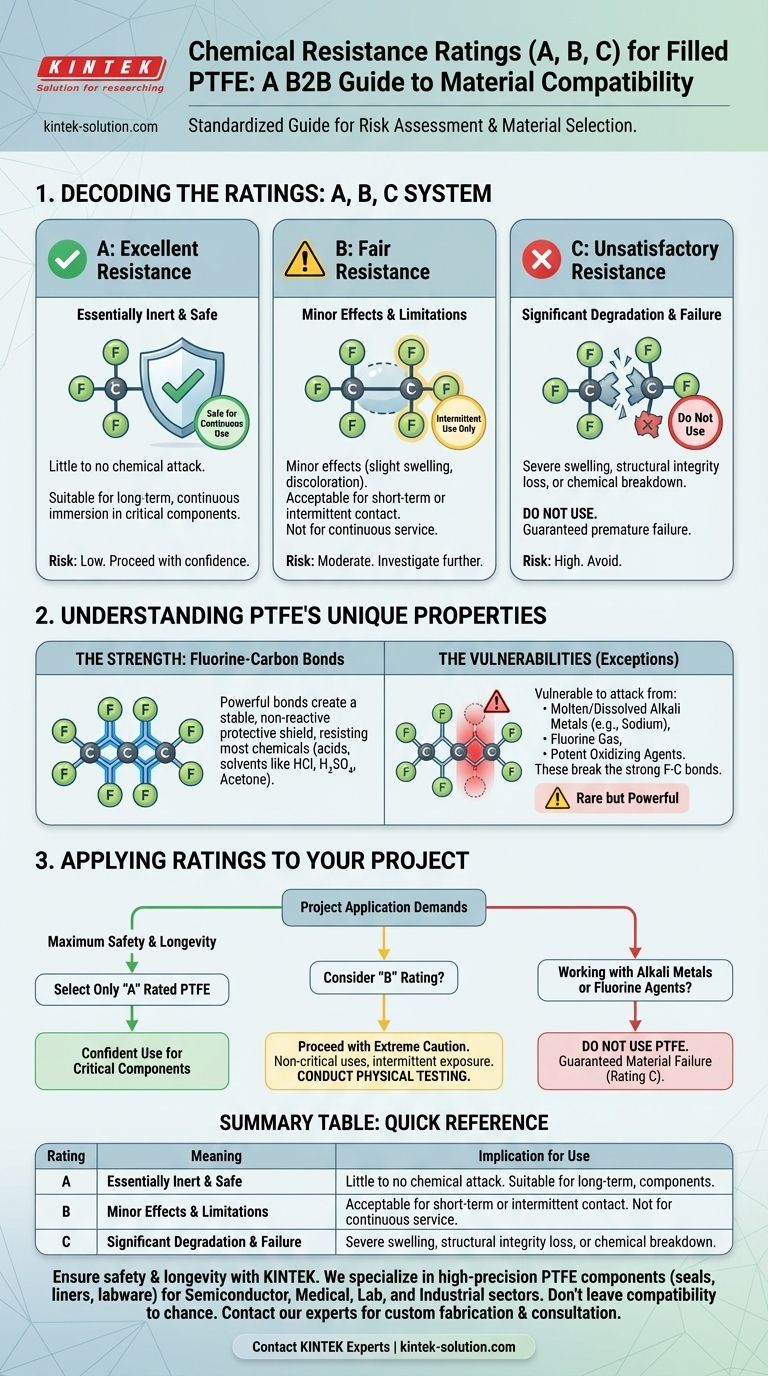

In chemical resistance charts for Filled PTFE, the ratings provide a clear, standardized guide to material compatibility. A rating of A indicates Excellent resistance, B signifies Fair resistance with some limitations, and C warns of Unsatisfactory resistance, meaning the material is not suitable for use.

Understanding these ratings is less about the letters themselves and more about risk assessment. While 'A' means you can proceed with confidence, 'B' is a strong signal to investigate further, as it implies potential degradation under specific conditions of temperature, concentration, or time.

Decoding the Chemical Resistance Ratings

The A-B-C system is a common industry standard designed to provide a quick reference for material selection. However, the practical implications of each grade are what truly matter for engineering and safety.

Rating A: Excellent Resistance

A rating of "Excellent" means that Filled PTFE experiences little to no chemical attack from the substance. The material is considered essentially inert in this application.

This grade is suitable for long-term, continuous immersion and is the required standard for critical components where material failure is not an option.

Rating B: Fair Resistance

This is the most nuanced rating. "Fair" resistance indicates that the material will experience minor effects from the chemical exposure.

This could manifest as slight swelling, discoloration, or a minor loss of physical properties over time. A "B" rating suggests the material may be acceptable for applications with short-term or intermittent contact, but it is generally not recommended for continuous service.

Rating C: Unsatisfactory Resistance

A "C" rating is a clear warning against using the material. Exposure to the chemical will cause significant degradation.

This can include severe swelling, loss of structural integrity, or a complete chemical breakdown of the PTFE. Using Filled PTFE in a "C" rated environment will almost certainly lead to premature component failure.

Understanding PTFE's Unique Properties

Polytetrafluoroethylene (PTFE) is renowned for its chemical inertness, but it's not invincible. Understanding its chemical makeup explains both its remarkable strengths and its specific weaknesses.

The Strength of Fluorine-Carbon Bonds

PTFE's incredible resistance comes from the powerful bonds between its carbon and fluorine atoms. The fluorine atoms form a tight, stable, and non-reactive protective "sheath" around the carbon backbone.

This structure makes it exceptionally difficult for most chemicals—including aggressive acids and solvents like hydrochloric acid, sulfuric acid, and acetone—to attack the polymer chain.

The Known Vulnerabilities

Despite its general stability, PTFE does have a few critical weaknesses that typically result in a "C" rating. These are the exceptions every engineer must know.

PTFE is not resistant to attack from molten or dissolved alkali metals (like sodium), fluorine gas, and other extremely potent oxidizing agents. These rare but powerful substances are among the few that can break the strong fluorine-carbon bonds.

How to Apply These Ratings to Your Project

Ultimately, these ratings are tools to guide your decision-making process. Use them to match the material's capabilities with your application's demands.

- If your primary focus is maximum safety and longevity: Only select Filled PTFE for applications where it holds an "A" rating against your specific chemical.

- If you are considering a material with a "B" rating: Proceed with extreme caution and consider it only for non-critical uses with intermittent exposure, and always conduct physical testing if possible.

- If you are working with alkali metals or potent fluorinating agents: Do not use PTFE, as its "C" rating in these environments guarantees material failure.

Always use these ratings as your first line of defense in ensuring the safety and reliability of your components.

Summary Table:

| Rating | Meaning | Implication for Use |

|---|---|---|

| A (Excellent) | Little to no chemical attack. Material is essentially inert. | Suitable for long-term, continuous immersion. The standard for critical components. |

| B (Fair) | Minor effects like slight swelling or discoloration may occur. | Acceptable for short-term or intermittent contact only. Not recommended for continuous service. |

| C (Unsatisfactory) | Significant degradation, including severe swelling or loss of integrity. | Not suitable. Will lead to premature component failure. |

Ensure the safety and longevity of your critical components.

Choosing the right material for harsh chemical environments is non-negotiable. At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your Filled PTFE parts are perfectly suited to withstand your specific chemical challenges.

Don't leave material compatibility to chance. Contact our experts today for a consultation on custom fabrication, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance