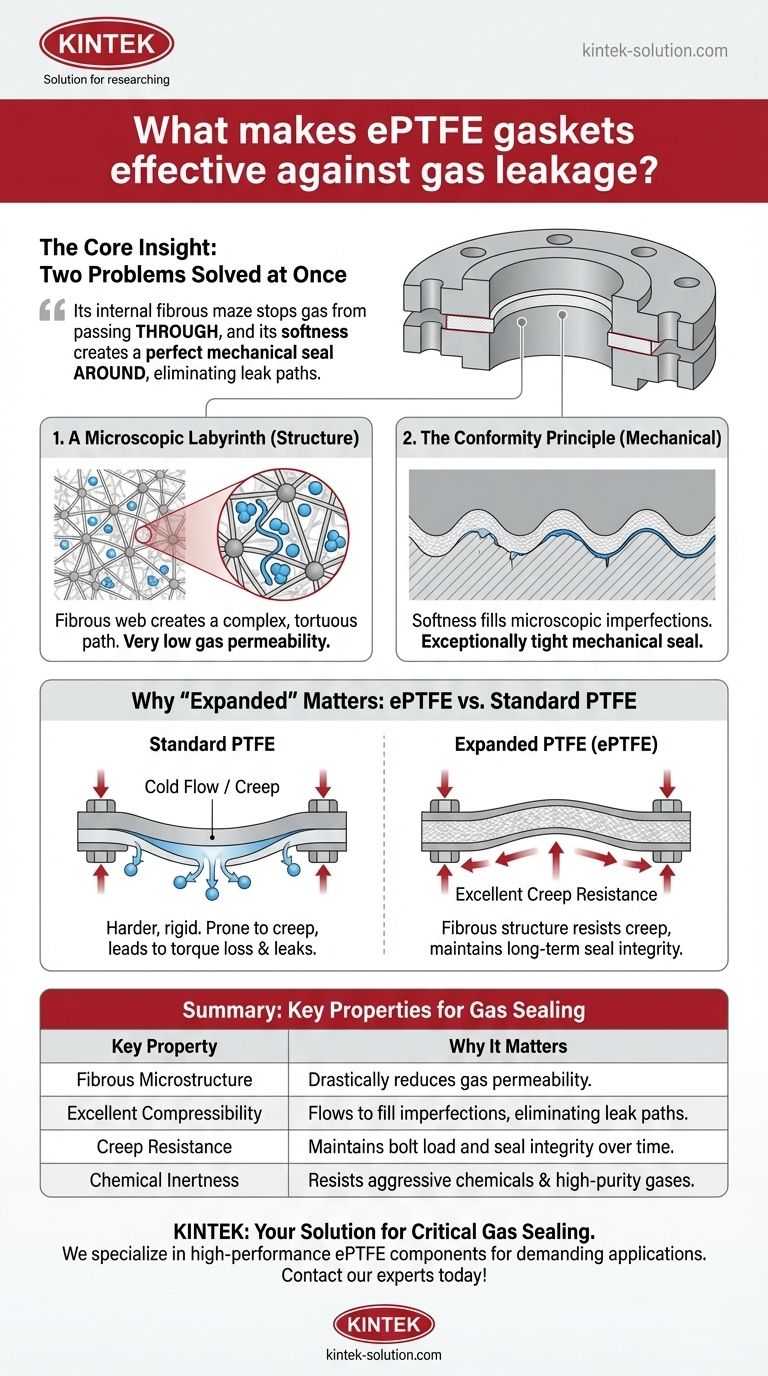

At its core, an ePTFE gasket's effectiveness against gas leakage comes from a powerful combination of its unique material structure and its superior mechanical properties. Its fine, dense, fibrous web creates a formidable barrier with extremely low gas permeability, while its excellent compressibility allows it to perfectly fill microscopic surface imperfections, creating an exceptionally tight seal.

The critical insight is that ePTFE (expanded Polytetrafluoroethylene) solves two problems at once: its internal fibrous maze stops gas from passing through the material, and its softness allows it to create a perfect mechanical seal around the material, eliminating common leak paths.

The Two Pillars of ePTFE Gas Sealing

To understand why ePTFE excels, we must look at how it functions on both a microscopic and a mechanical level. These two aspects work in concert to prevent gas from escaping.

A Microscopic Labyrinth: The Role of Material Structure

The manufacturing process for ePTFE creates a unique microstructure of solid PTFE nodes interconnected by a web of fine, strong fibers.

This multi-directional fibrous structure creates an incredibly complex and tortuous path. Gas molecules attempting to permeate the gasket material cannot find a direct route through, resulting in very low gas permeability.

The Conformity Principle: Mechanical Sealing

Gases will exploit the smallest imperfections, such as scratches or waviness on a flange face. The key to a gas-tight seal is a gasket that can flow into and completely fill these voids.

This is where ePTFE's good compressibility is critical. Unlike harder materials, soft ePTFE deforms under load, conforming precisely to the sealing surfaces and eliminating potential leak paths that rigid gaskets would miss.

Why "Expanded" PTFE is the Critical Distinction

It is crucial to understand that not all PTFE gaskets are created equal. The term "expanded" signifies a profound difference in performance, especially in gas applications.

Standard PTFE vs. Expanded PTFE (ePTFE)

Standard, non-expanded PTFE gaskets are typically harder and more rigid. As some findings show, certain PTFE ring gaskets can have a higher leakage rate precisely because of this increased hardness.

They cannot conform to surface imperfections as effectively, requiring higher bolt loads and near-perfect flange surfaces to achieve an acceptable seal.

Overcoming Creep and Cold Flow

A common failure mode for standard PTFE is "cold flow," or creep, where the material slowly flows outward from under the compressive load of the flanges. This causes a loss of bolt torque and, eventually, a leak.

The fibrous, interlocking structure of ePTFE provides excellent resistance to this phenomenon. The fibers create a stable material that maintains its shape and compressive stress over time, ensuring a long-term, reliable seal.

Common Pitfalls and Considerations

While ePTFE is a superior material for gas sealing, its effectiveness is not automatic. Understanding its limitations is key to successful application.

The Myth of "One-Size-Fits-All" PTFE

The most common mistake is assuming all "PTFE" gaskets perform the same. A solid, skived PTFE ring gasket is a fundamentally different product from a multi-directionally expanded ePTFE sheet gasket. For critical gas service, specifying ePTFE is essential.

Flange Condition and Preparation

Even with ePTFE's excellent conformability, it cannot compensate for severely damaged or warped flanges. Proper surface preparation and ensuring flanges are clean and within acceptable flatness tolerances are still vital for creating a reliable seal.

The Importance of Correct Installation

The final seal integrity depends entirely on proper installation. Achieving the correct compressive stress through controlled, even bolt torque is non-negotiable. Without sufficient compression, the ePTFE cannot fully conform to the surfaces to do its job.

Making the Right Choice for Your Application

Selecting the right gasket requires matching the material's properties to the demands of the service.

- If your primary focus is sealing hazardous or high-purity gases: ePTFE is a premier choice due to its combination of low permeability, chemical inertness, and exceptional conformability.

- If you are dealing with older, worn, or imperfect flange surfaces: The superior compressibility of ePTFE makes it far more forgiving and reliable than harder, rigid gasket types.

- If your application is sensitive to bolt torque loss over time: The creep resistance of ePTFE provides a more stable and durable seal compared to standard PTFE.

By understanding the unique fibrous structure of ePTFE, you can specify a gasket with confidence, ensuring a safe and reliable gas seal for your most critical applications.

Summary Table:

| Key Property | Why It Matters for Gas Sealing |

|---|---|

| Fibrous Microstructure | Creates a tortuous path that drastically reduces gas permeability. |

| Excellent Compressibility | Flows to fill surface imperfections, eliminating leak paths. |

| Creep Resistance | Maintains bolt load and seal integrity over time, unlike standard PTFE. |

| Chemical Inertness | Resists a wide range of aggressive chemicals and high-purity gases. |

Need a reliable gas seal for a critical application? The unique properties of expanded PTFE (ePTFE) are engineered to solve your toughest sealing challenges. KINTEK specializes in manufacturing high-performance PTFE and ePTFE components—including custom gaskets, seals, and liners—for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision and offer custom fabrication from prototypes to high-volume orders to meet your exact specifications. Let us provide the sealing solution you can depend on. Contact our experts today to discuss your project!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the chemical resistance properties of Teflon (PTFE) balls? Unmatched Inertness for Harsh Environments

- Why are PTFE rotary shaft seals essential for high-performance applications? Unlock Unmatched Reliability in Extreme Conditions

- What is the chemical resistance of Virgin PTFE? Unmatched Inertness for Harsh Chemical Environments

- What advantages do Teflon O-rings offer? Superior Sealing for Extreme Conditions

- How do PTFE gaskets improve sealing efficiency? Achieve Leak-Proof Performance in Harsh Environments

- What types of applications are PTFE gaskets suitable for? The Ultimate Guide for Extreme Environments

- What are the properties of Teflon balls? Unlock Elite Chemical & Friction Resistance

- What are the key properties of PTFE seals and rings? Unlock Superior Performance in Harsh Environments