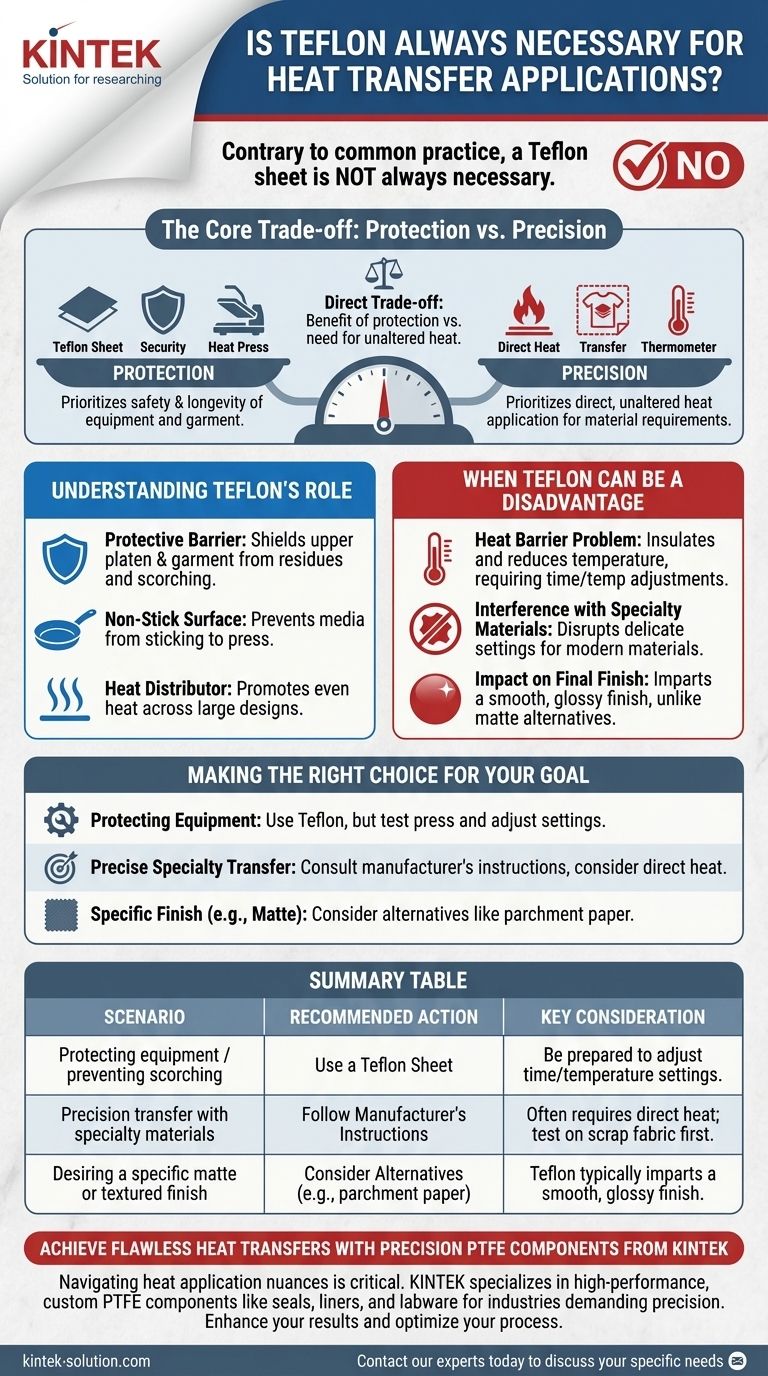

Contrary to common practice, a Teflon sheet is not always necessary for heat transfer applications. While it serves as a valuable protective layer, it can also act as a heat barrier, potentially interfering with the precise temperature required for certain transfers. The decision to use one ultimately depends on the specific materials you are working with and the final result you want to achieve.

The core decision to use a Teflon sheet is a direct trade-off. You must weigh the benefit of protecting your equipment and garment against the need for direct, unaltered heat application required by your specific transfer material.

Understanding Teflon's Role in Heat Transfer

Teflon, known chemically as Polytetrafluoroethylene (PTFE), is used in heat pressing because of its unique combination of properties. Understanding these roles is key to deciding when it's appropriate to use.

The Protective Barrier

A Teflon sheet acts as a reusable, durable shield. It protects the upper platen of your heat press from any inks, adhesives, or residues from your transfer material, making cleanup simple and preventing cross-contamination between projects.

It also protects the garment itself from direct contact with the hot metal platen, which can help prevent scorching on sensitive fabrics.

The Non-Stick Surface

The most well-known property of Teflon is its non-stick nature. This prevents heat transfer vinyl (HTV) or other transfer media from accidentally melting onto and sticking to your heat press, which would otherwise ruin both the machine and your project.

The Heat Distributor

While it can act as a barrier, a Teflon sheet can also help distribute the heat from the platen more evenly across the surface of the transfer. This can be beneficial for ensuring a consistent application, especially on larger designs.

When a Teflon Sheet Can Be a Disadvantage

Despite its benefits, there are clear situations where using a Teflon sheet can be counterproductive. Its presence fundamentally changes the heat equation, which can lead to application issues.

The Heat Barrier Problem

The most significant drawback is that Teflon is an insulator. It creates a barrier that can reduce the actual temperature reaching your design. This may lead to under-application, causing the transfer to adhere poorly or wash off prematurely.

To compensate, you often need to increase the temperature or the pressing time, which introduces variables that can complicate an otherwise precise process.

Interference with Specialty Materials

Many modern heat transfer materials are engineered for very specific temperature and time settings. Adding a Teflon sheet can disrupt this delicate balance, causing an improper transfer. For these materials, direct heat or a different type of cover sheet (like parchment paper) may be recommended by the manufacturer.

Impact on Final Finish

A Teflon sheet typically imparts a smooth, slightly glossy finish to the pressed design. If you desire a more matte or textured look that integrates with the fabric, forgoing the sheet or using an alternative like craft paper may yield a better result.

Understanding the Trade-offs

Choosing whether to use a Teflon sheet is not about right or wrong; it's about understanding the compromises you are making for a specific outcome.

Protection vs. Precision

The central trade-off is between protection and precision. Using Teflon prioritizes the safety and longevity of your equipment and prevents scorching on your garment. Forgoing it prioritizes the direct, unaltered application of heat exactly as the transfer manufacturer intended.

Efficiency vs. Consistency

A Teflon sheet can reduce efficiency by requiring longer press times or higher temperatures to achieve proper adhesion. However, it can increase consistency by providing a reliable protective buffer that prevents costly mistakes like melted vinyl on your platen.

Making the Right Choice for Your Goal

Your decision should be guided by your primary objective for each specific project.

- If your primary focus is protecting your equipment and preventing scorching: Use a Teflon sheet, but always be prepared to perform a test press and adjust your settings to ensure a full application.

- If your primary focus is achieving a precise transfer with specialty vinyl: Consult the manufacturer's instructions. If they recommend no cover sheet, test on a scrap piece of fabric first to mitigate risk.

- If your primary focus is achieving a specific finish (like matte): Consider using parchment paper or a craft paper cover sheet as an alternative to Teflon.

Ultimately, mastering your heat transfer process comes from understanding how each component affects the final result.

Summary Table:

| Scenario | Recommended Action | Key Consideration |

|---|---|---|

| Protecting equipment/preventing scorching | Use a Teflon Sheet | Be prepared to adjust time/temperature settings to compensate for heat barrier. |

| Precision transfer with specialty materials | Follow Manufacturer's Instructions | Often requires direct heat; test on scrap fabric first. |

| Desiring a specific matte or textured finish | Consider Alternatives (e.g., parchment paper) | Teflon typically imparts a smooth, glossy finish. |

Achieve Flawless Heat Transfers with Precision PTFE Components from KINTEK

Navigating the nuances of heat application is critical. For industries where precision and reliability are non-negotiable—such as semiconductor, medical, and laboratory applications—the right PTFE component makes all the difference.

At KINTEK, we specialize in manufacturing high-performance, custom PTFE components like seals, liners, and labware. We ensure your equipment operates with exacting standards, whether you need prototypes or high-volume orders.

Let us help you optimize your process. Contact our experts today to discuss your specific needs and discover how our precision PTFE solutions can enhance your results.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability