In the most demanding industrial applications, Polytetrafluoroethylene (PTFE) bellows stand apart due to a unique combination of properties. Their primary advantages are near-universal chemical inertness, exceptional durability that lowers long-term costs, a non-stick surface that ensures system purity and efficiency, and a wide operating temperature range.

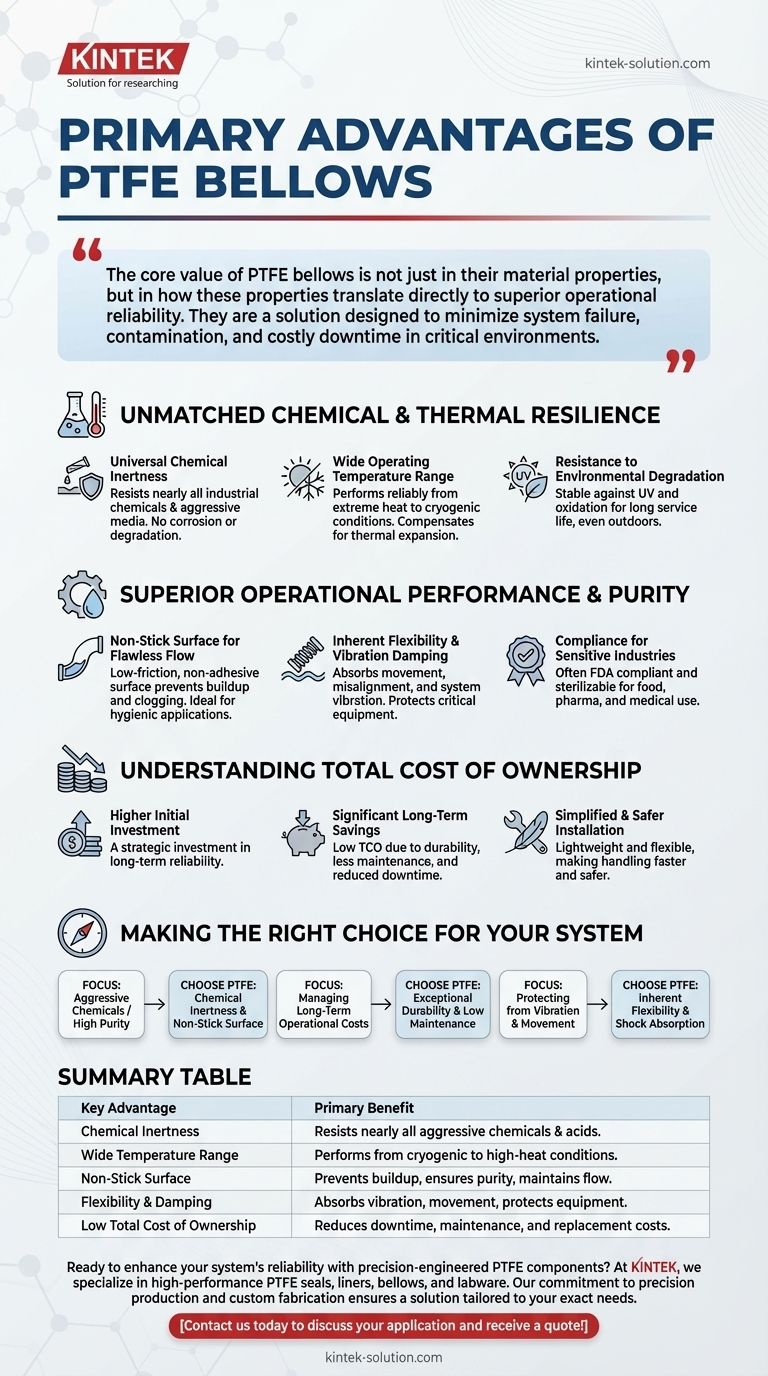

The core value of PTFE bellows is not just in their material properties, but in how these properties translate directly to superior operational reliability. They are a solution designed to minimize system failure, contamination, and costly downtime in critical environments.

The Unmatched Chemical and Thermal Resilience

The fundamental advantage of PTFE lies in its molecular structure, which provides a level of stability that few other materials can match. This stability is the source of its most valued characteristics.

Universal Chemical Inertness

PTFE is renowned for its resistance to nearly all industrial chemicals, acids, and corrosive agents. This makes it the default choice for systems handling aggressive media in industries from petrochemicals to semiconductor manufacturing.

Unlike metal or other polymer bellows, PTFE will not corrode or degrade, ensuring the integrity of the bellow and preventing contamination of the process fluid.

Wide Operating Temperature Range

These bellows perform reliably across an exceptionally broad range of temperatures. This allows them to maintain their structural integrity and flexibility in both extreme heat and cryogenic conditions, compensating for thermal expansion and contraction in pipelines.

Resistance to Environmental Degradation

PTFE is inherently stable and resistant to environmental factors like UV radiation and oxidation. This ensures a long service life even when installed in outdoor or exposed applications, preventing premature material failure.

Superior Operational Performance and Purity

Beyond simple resilience, PTFE bellows are engineered to enhance the efficiency and cleanliness of the systems they protect. Their physical properties actively contribute to better performance.

Non-Stick Surface for Flawless Flow

The material possesses an extremely low-friction, non-adhesive surface. This "non-stick" quality is critical for preventing the buildup of deposits, sludge, or biological matter within the system.

This ensures consistent, efficient fluid flow, reduces the risk of blockages, and makes PTFE bellows ideal for hygienic applications where purity is paramount.

Inherent Flexibility and Vibration Damping

A primary function of any bellow is to absorb movement. PTFE offers high flexibility, allowing it to effectively compensate for misalignment, axial movement, and system vibration.

This ability to absorb shock and movement protects pumps, vessels, and other critical equipment from mechanical stress, extending the life of the entire system.

Compliance for Sensitive Industries

PTFE is often compliant with strict industry standards, including FDA regulations. Its ability to be sterilized makes it a premier choice for food production, pharmaceutical processing, and medical appliances where preventing contamination is non-negotiable.

Understanding the Total Cost of Ownership

While PTFE bellows may have a different cost profile than some alternatives, a true assessment must look beyond the initial purchase price. The real value is revealed over the component's entire lifecycle.

The Higher Initial Investment

It is important to acknowledge that PTFE expansion bellows can have a higher upfront cost compared to some simpler alternatives. However, this initial expense is an investment in long-term reliability.

Significant Long-Term Savings

The true economic advantage lies in the low total cost of ownership. PTFE's durability, resistance to wear, and immunity to corrosion drastically reduce the need for maintenance and frequent replacements.

This translates to significant savings by minimizing process downtime, eliminating repair costs, and lowering labor expenses over the system's lifespan.

Simplified and Safer Installation

Compared to heavy and rigid metal bellows, PTFE components are remarkably lightweight and flexible. This simplifies handling and makes installation faster and safer, often requiring minimal labor and no specialized tools.

Making the Right Choice for Your System

Selecting the correct bellow material is a critical engineering decision. The advantages of PTFE make it a clear choice for specific operational priorities.

- If your primary focus is handling aggressive chemicals or maintaining high purity: PTFE's chemical inertness and non-stick surface make it the superior and often necessary choice.

- If your primary focus is managing long-term operational costs: The exceptional durability and low maintenance of PTFE provide a clear return on investment by eliminating the frequent costs associated with downtime and replacement.

- If your primary focus is protecting sensitive equipment from vibration and movement: PTFE’s inherent flexibility provides reliable shock absorption, safeguarding the entire processing system.

Ultimately, choosing PTFE bellows is a strategic decision for ensuring long-term system integrity and operational peace of mind.

Summary Table:

| Key Advantage | Primary Benefit |

|---|---|

| Chemical Inertness | Resists nearly all aggressive chemicals and acids. |

| Wide Temperature Range | Performs reliably from cryogenic to high-heat conditions. |

| Non-Stick Surface | Prevents buildup, ensures purity, and maintains flow. |

| Flexibility & Damping | Absorbs vibration, movement, and protects equipment. |

| Low Total Cost of Ownership | Reduces downtime, maintenance, and replacement costs. |

Ready to enhance your system's reliability with precision-engineered PTFE components?

At KINTEK, we specialize in manufacturing high-performance PTFE seals, liners, bellows, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our commitment to precision production and custom fabrication—from prototypes to high-volume orders—ensures you get a solution tailored to your exact needs, delivering superior chemical resistance, purity, and long-term cost savings.

Contact us today to discuss your application and receive a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems