At its core, a PTFE bar is manufactured from Polytetrafluoroethylene (PTFE) resin. This base resin is either used in its pure, "virgin" form or is blended with various filler materials. These fillers, such as glass, carbon, or bronze, are added to enhance specific mechanical or thermal properties that virgin PTFE lacks on its own.

The essential material for any PTFE bar is the PTFE polymer resin itself. The critical choice for any application, however, lies in deciding between pure (virgin) PTFE for its chemical inertness and filled PTFE for its superior mechanical strength, wear resistance, and thermal stability.

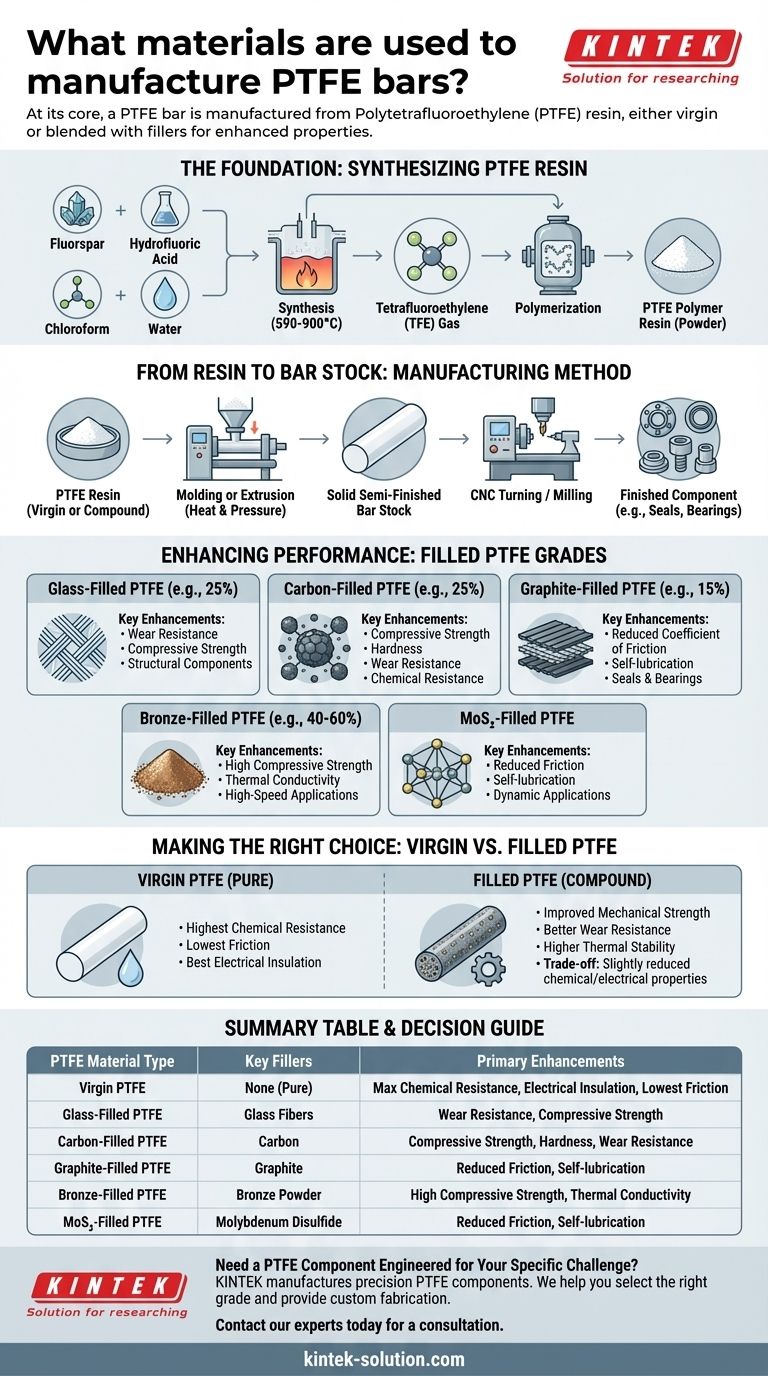

The Foundation: Synthesizing the PTFE Resin

Before a bar can be formed, the base PTFE polymer must be created through a complex chemical process. This provides the foundation for all subsequent variations.

The Raw Ingredients

The synthesis of PTFE begins with four primary ingredients: fluorspar, hydrofluoric acid, chloroform, and water. These materials serve as the chemical building blocks for the polymer.

The Synthesis and Polymerization Process

These ingredients are combined in a specialized, heated reaction chamber. At very high temperatures (between 590-900°C), they react to synthesize tetrafluoroethylene (TFE) gas.

This TFE monomer is then polymerized—a process where individual molecules link together into long chains—to form the stable, non-reactive polymer we know as Polytetrafluoroethylene (PTFE).

From Resin to Bar Stock: The Manufacturing Method

Once the raw PTFE resin is produced (typically as a powder), it must be consolidated into a solid, usable form like a rod or bar.

Forming the Bar

The PTFE resin, either in its virgin state or as a compound mixed with fillers, is processed using methods like molding or extrusion. This process compacts the resin under heat and pressure to create a solid, semi-finished "stock" shape, such as a cylindrical bar.

Creating the Final Component

These bars are considered semi-finished stock. They are typically machined using techniques like CNC turning or milling to produce finished components like seals, bushings, bearings, and insulators.

Enhancing Performance: Understanding Filled PTFE Grades

While virgin PTFE has exceptional properties, it has mechanical limitations. Fillers are added to create compounds that overcome these weaknesses for demanding applications.

The Purpose of Fillers

Fillers are added to the base PTFE resin to improve properties like compressive strength, wear resistance, thermal conductivity, and resistance to creep (cold flow under load).

Glass-Filled PTFE

Adding glass fibers (typically 25%) significantly increases wear resistance and compressive strength. It is one of the most common fillers used for structural components.

Carbon-Filled PTFE

Carbon (typically 25%) enhances compressive strength, hardness, and wear resistance. It also provides good chemical resistance in corrosive environments.

Graphite-Filled PTFE

Graphite (typically 15%) is added primarily to reduce the coefficient of friction. It also improves wear properties, making it ideal for self-lubricating seals and bearings.

Bronze-Filled PTFE

Adding bronze powder (40% to 60%) dramatically increases compressive strength and thermal conductivity, allowing heat to dissipate more effectively in high-speed applications.

MoS₂ (Molybdenum Disulfide) Filled PTFE

Like graphite, MoS₂ is added in small amounts to reduce friction and improve the self-lubricating properties of the material, especially in dynamic applications.

Understanding the Trade-offs: Virgin vs. Filled PTFE

Choosing the right material requires understanding the compromises between the pure polymer and its enhanced variations. There is no single "best" option, only the right fit for a specific problem.

The Case for Virgin PTFE

Virgin PTFE offers the highest chemical resistance, the lowest coefficient of friction of any solid, and the best electrical insulation properties. It is the ideal choice when absolute purity and inertness are required.

The Limitations of Virgin PTFE

The primary weaknesses of virgin PTFE are its poor resistance to wear and its tendency to creep, or deform under sustained pressure. It is a relatively soft material.

When to Choose Filled PTFE

Filled grades are chosen when mechanical performance is more important than the absolute purity of virgin PTFE. The addition of fillers almost always improves mechanical strength and dimensional stability at the cost of slightly reduced chemical resistance and electrical insulation.

Making the Right Choice for Your Application

Your selection should be dictated entirely by the primary demands of your project's environment and performance requirements.

- If your primary focus is maximum chemical resistance or electrical insulation: Choose virgin PTFE for its unmatched purity and dielectric strength.

- If your primary focus is high wear resistance and compressive strength: Consider glass-filled or carbon-filled PTFE for durable mechanical parts.

- If your primary focus is the lowest possible friction for dynamic seals: Graphite-filled or MoS₂-filled PTFE are excellent self-lubricating choices.

- If your primary focus is thermal conductivity and high load-bearing capacity: Bronze-filled PTFE is the standard for demanding bearing and bushing applications.

Understanding the composition of PTFE bars empowers you to select a material precisely engineered to solve your specific challenge.

Summary Table:

| PTFE Material Type | Key Fillers | Primary Property Enhancements |

|---|---|---|

| Virgin PTFE | None (Pure) | Maximum chemical resistance, electrical insulation, lowest friction |

| Glass-Filled PTFE | Glass Fibers | Wear resistance, compressive strength |

| Carbon-Filled PTFE | Carbon | Compressive strength, hardness, wear resistance |

| Graphite-Filled PTFE | Graphite | Reduced friction, self-lubrication |

| Bronze-Filled PTFE | Bronze Powder | High compressive strength, thermal conductivity |

| MoS₂-Filled PTFE | Molybdenum Disulfide | Reduced friction, self-lubrication |

Need a PTFE Component Engineered for Your Specific Challenge?

Understanding the material is the first step. KINTEK manufactures precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We help you select the right PTFE grade (virgin or filled) and provide custom fabrication from prototypes to high-volume orders, ensuring optimal performance for your application.

Let's discuss your project requirements and material needs. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection