To be direct, PTFE oil seals demonstrate significantly higher pressure resistance than conventional rubber oil seals. A single-lip PTFE seal can typically withstand pressures up to 1.0 MPa (megapascals), while a double-lip design can handle up to 3.0 MPa, making them suitable for more demanding applications. Conventional seals are generally intended for lower-pressure environments common in general machinery.

The core takeaway is that while PTFE seals are definitively superior in high-pressure scenarios, their true value is realized when you also consider their exceptional resistance to chemicals, heat, and friction. The choice between PTFE and conventional seals is a strategic decision based on the total operational demand, not just a single pressure rating.

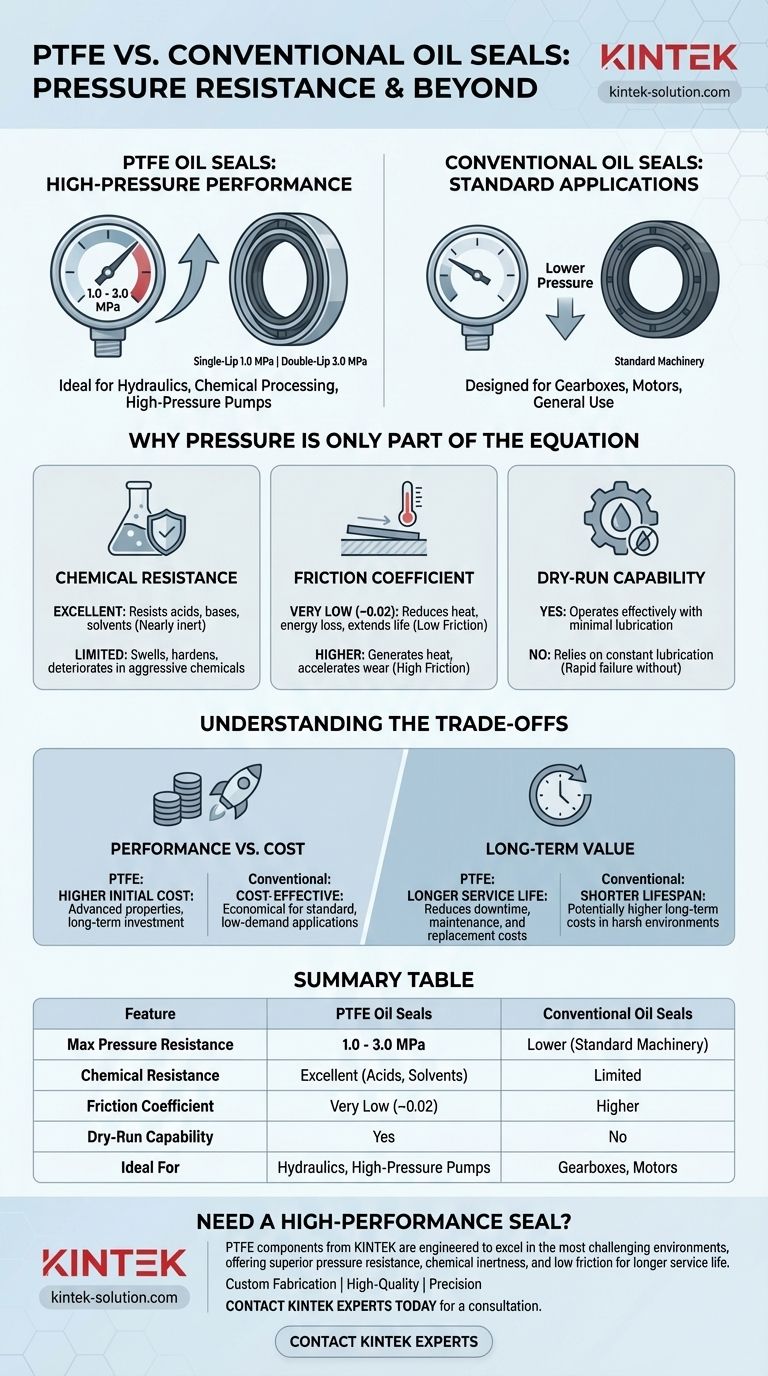

A Direct Comparison of Pressure Capabilities

Understanding the fundamental design differences explains the performance gap between these two types of seals. Each is engineered for a distinct operational window.

PTFE Seals: Engineered for High-Pressure Environments

PTFE (Polytetrafluoroethylene) seals are constructed from a robust, low-friction material that maintains its structural integrity under significant force.

Their ability to handle pressures from 1.0 to 3.0 MPa makes them the standard choice for hydraulic systems, high-pressure pumps, and other equipment where containing fluids under force is critical.

Conventional Seals: The Standard for Lower Pressures

Conventional oil seals, typically made from nitrile or other elastomers, are designed for excellent sealing in common mechanical applications.

They perform reliably in environments like gearboxes and electric motors where the primary goal is retaining lubrication under minimal pressure. They are not suited for the high-pressure dynamic systems where PTFE excels.

Why Pressure is Only Part of the Equation

A seal's ability to withstand pressure is critical, but its operational success depends on its performance across several other factors. The underlying material properties are what truly differentiate PTFE from conventional seals.

Unmatched Chemical Resistance

PTFE is nearly inert, resisting erosion from almost all chemicals, including strong acids, bases, and solvents. This makes it essential for chemical processing and pharmaceutical applications.

Conventional rubber seals, in contrast, can swell, harden, or deteriorate when exposed to aggressive chemicals, leading to premature failure.

The Critical Role of Friction

PTFE has an exceptionally low coefficient of friction (around 0.02). This unique property, known as "slipperiness," dramatically reduces heat generation and energy loss during operation.

Higher friction in conventional seals generates heat, which can degrade the sealing material and the lubricant, accelerating wear and reducing the seal's lifespan.

Lubrication Requirements

The low-friction nature of PTFE allows it to operate effectively even with minimal lubrication, a condition known as dry running. This provides a safety margin if lubrication flow is interrupted.

Conventional seals rely entirely on a stable lubricating oil film to function. Insufficient lubrication leads to rapid overheating, wear, and inevitable leakage.

Understanding the Trade-offs

Selecting the correct seal requires balancing performance requirements with economic realities. The ideal choice for one application may be entirely wrong for another.

Performance vs. Cost

There is a clear cost distinction. PTFE's advanced properties and manufacturing process result in a higher initial purchase price.

Conventional rubber seals are a highly cost-effective solution for the vast number of standard applications where extreme pressure, temperatures, or chemicals are not a factor.

Long-Term Value and Service Life

In demanding environments, the superior wear resistance of PTFE translates to a significantly longer service life. This reduces equipment downtime, maintenance labor, and replacement costs.

While less expensive upfront, a conventional seal placed in an overly harsh environment will fail quickly, leading to higher long-term operational costs and potential equipment damage.

Making the Right Choice for Your Application

Use your specific operational goal as the primary filter for selecting the right seal.

- If your primary focus is high-pressure sealing (up to 3 MPa) in an aggressive chemical environment: PTFE is the definitive choice for ensuring reliability and long service life.

- If your primary focus is a cost-effective solution for standard, low-pressure applications: A conventional rubber oil seal provides reliable performance and is the most economical option.

- If your primary focus is reducing energy loss and enabling dry-run capability: PTFE's extremely low friction coefficient makes it the superior choice for high-efficiency or critical equipment.

By understanding the complete performance profile beyond a single metric, you can select a seal that ensures both operational reliability and long-term value.

Summary Table:

| Feature | PTFE Oil Seals | Conventional Oil Seals |

|---|---|---|

| Max Pressure Resistance | 1.0 - 3.0 MPa | Lower (Standard Machinery) |

| Chemical Resistance | Excellent (Acids, Solvents) | Limited |

| Friction Coefficient | Very Low (~0.02) | Higher |

| Dry-Run Capability | Yes | No |

| Ideal For | Hydraulics, Chemical Processing, High-Pressure Pumps | Gearboxes, Motors, Standard Machinery |

Need a High-Performance Seal for Demanding Conditions?

Your equipment's reliability depends on the right seal. PTFE components from KINTEK are engineered to excel in the most challenging environments, offering superior pressure resistance, chemical inertness, and low friction for longer service life and reduced downtime.

We specialize in custom fabricating high-quality PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. From prototypes to high-volume orders, we prioritize precision to meet your exact specifications.

Let's engineer your solution. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the benefits of PTFE seals in terms of prototyping and production? Accelerate R&D and Ensure Elite Performance

- What is the overall operating temperature range for PTFE seals, gaskets, and O-rings? Achieve Sealing Integrity from -200°C to +260°C

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- What are the key properties of PTFE that make it suitable for seals? Unlock Reliability in Extreme Conditions