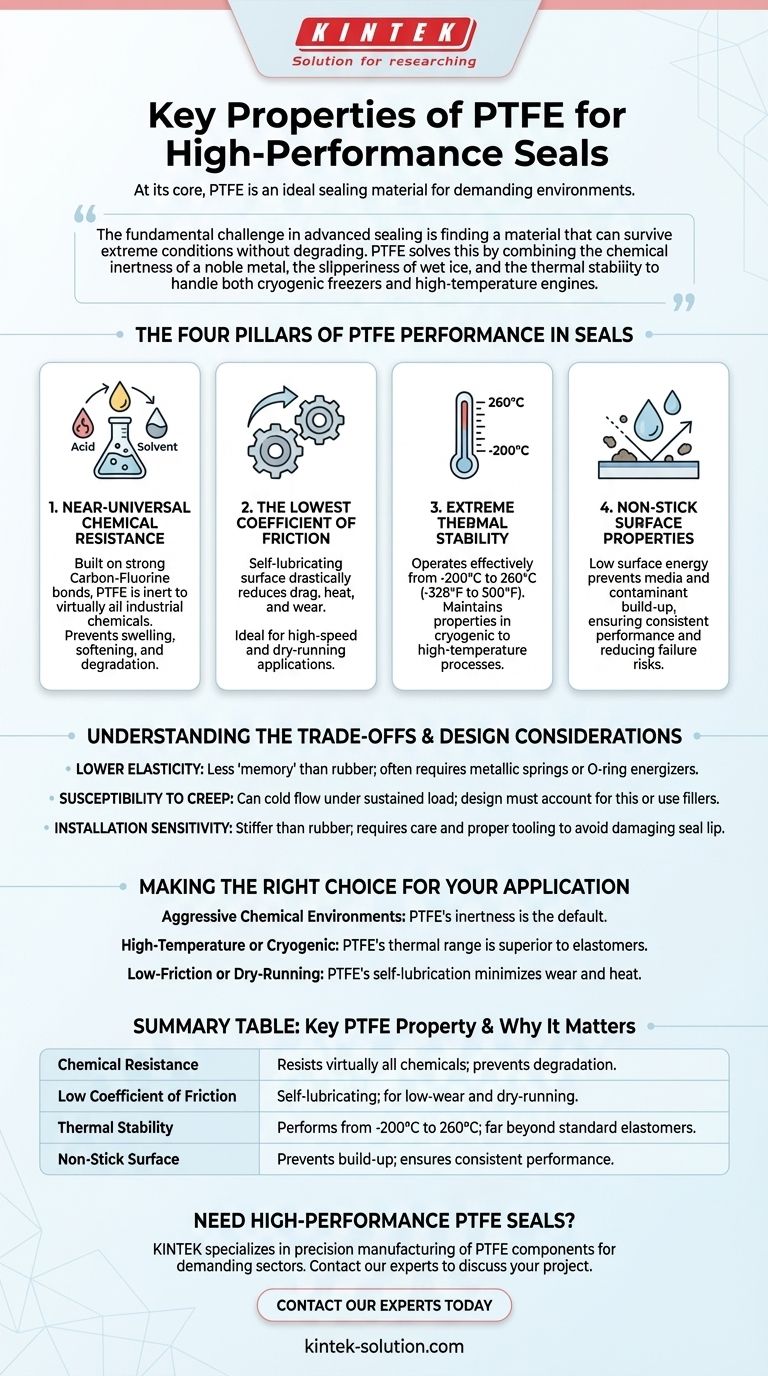

At its core, PTFE is an ideal sealing material due to a unique combination of four key properties. Its near-universal chemical resistance, an extremely low coefficient of friction, a wide operational temperature range, and excellent non-stick characteristics allow it to perform reliably in demanding environments where most other materials would quickly fail.

The fundamental challenge in advanced sealing is finding a material that can survive extreme conditions without degrading. PTFE solves this by combining the chemical inertness of a noble metal, the slipperiness of wet ice, and the thermal stability to handle both cryogenic freezers and high-temperature engines.

The Four Pillars of PTFE Performance in Seals

The effectiveness of Polytetrafluoroethylene (PTFE) in sealing applications stems directly from its unique molecular structure. Understanding these core properties explains why it has become a default choice for high-performance systems.

1. Near-Universal Chemical Resistance

PTFE is one of the most chemically inert materials known, earning it the nickname "the king of plastics." Its structure, built on strong carbon-fluorine (C-F) bonds, makes it resistant to virtually all industrial chemicals, including aggressive acids, alkalis, oils, and solvents.

This inertness ensures the seal will not swell, soften, or degrade when exposed to corrosive media, maintaining its structural integrity and sealing capability over its entire service life.

2. The Lowest Coefficient of Friction

PTFE possesses the lowest coefficient of friction of any known solid material. This creates a self-lubricating surface that drastically reduces rotational drag, heat generation, and wear on both the seal and the shaft.

This property is critical in high-speed applications and makes PTFE suitable for dry running, where external lubrication is either impossible or undesirable.

3. Extreme Thermal Stability

PTFE seals operate effectively across an exceptionally broad temperature range, typically from -200°C to 260°C (-328°F to 500°F).

This allows it to maintain its sealing properties in everything from cryogenic applications to high-temperature industrial processes, environments where conventional elastomers would become brittle or melt.

4. Non-Stick Surface Properties

The material's extremely low surface energy gives it powerful non-stick, or hydrophobic, properties. This prevents media, contaminants, or sludge from adhering to the seal lip.

A non-stick surface ensures consistent performance and prevents contaminant build-up that could otherwise compromise the sealing interface and lead to premature failure.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not a universal solution. Acknowledging its limitations is key to successful application design.

Lower Elasticity

Compared to traditional rubber elastomers, PTFE is a relatively rigid material. It has less "memory" and does not rebound as effectively after being compressed.

Because of this, many PTFE seal designs incorporate a metallic spring or an elastomeric O-ring as an energizer. This energizer provides the constant force needed to keep the seal lip pressed firmly against the shaft.

Susceptibility to Creep

Under a sustained load, especially at elevated temperatures, PTFE can be subject to "creep," or cold flow. This is a slow, permanent deformation of the material over time.

Seal and gland design must account for this phenomenon to ensure that the seal maintains the proper contact pressure throughout its intended lifespan. Fillers are often added to PTFE compounds to improve creep resistance.

Installation Sensitivity

The relative stiffness of PTFE can make installation more challenging than with flexible rubber seals. Special care and proper tooling are required to avoid scratching or damaging the seal lip, as any imperfection can create a leak path.

Making the Right Choice for Your Application

Selecting the right seal material requires matching its properties to the primary demands of your system.

- If your primary focus is aggressive chemical environments: PTFE's chemical inertness makes it the default choice where other materials would corrode or swell.

- If your primary focus is high-temperature or cryogenic performance: The exceptional thermal range of PTFE ensures seal integrity in conditions that would destroy conventional elastomers.

- If your primary focus is low-friction or dry-running applications: PTFE's self-lubricating properties minimize wear and heat, extending the service life of both the seal and its mating components.

Ultimately, selecting PTFE is a strategic decision for applications where performance and reliability in extreme conditions are non-negotiable.

Summary Table:

| Key PTFE Property | Why It Matters for Seals |

|---|---|

| Chemical Resistance | Resists virtually all acids, alkalis, and solvents, preventing degradation. |

| Low Coefficient of Friction | Self-lubricating; ideal for low-wear and dry-running applications. |

| Thermal Stability | Performs from -200°C to 260°C, far beyond the range of standard elastomers. |

| Non-Stick Surface | Prevents media build-up, ensuring consistent performance and preventing failure. |

Need High-Performance PTFE Seals for Your Application?

PTFE's unique properties make it the superior choice for sealing solutions in the most demanding environments. At KINTEK, we specialize in the precision manufacturing of PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We understand that a perfect seal is critical to your system's reliability and performance. Our expertise ensures you get a component that is precisely engineered for your specific temperature, chemical, and friction requirements, from prototypes to high-volume production.

Let's engineer your solution together. Contact our experts today to discuss your project and receive a quote.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main chemical resistance properties of PTFE-coated O-rings? Uncover the True Role of the Coating

- What are the two temperature extremes discussed for PTFE seals? Maximize Performance from Cryogenic to High-Heat

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance

- What are the benefits of using PTFE seals? Unmatched Chemical & Temperature Resistance

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions