In athletic footwear, PTFE provides critical advantages by enhancing reliability, stability, and durability. Its most significant benefits are realized in two key areas: creating a low-friction system for laces and eyelets to prevent loosening, and forming a non-stick surface on cleats to repel mud and grass, which preserves traction and keeps the shoe lightweight during play.

PTFE's value in footwear is not about a single benefit, but its unique ability to solve two persistent athletic problems: inconsistent fit from binding laces and reduced performance from debris buildup on outsoles. Its core properties—an extremely low coefficient of friction and a non-stick surface—directly translate into improved reliability and stability for the athlete.

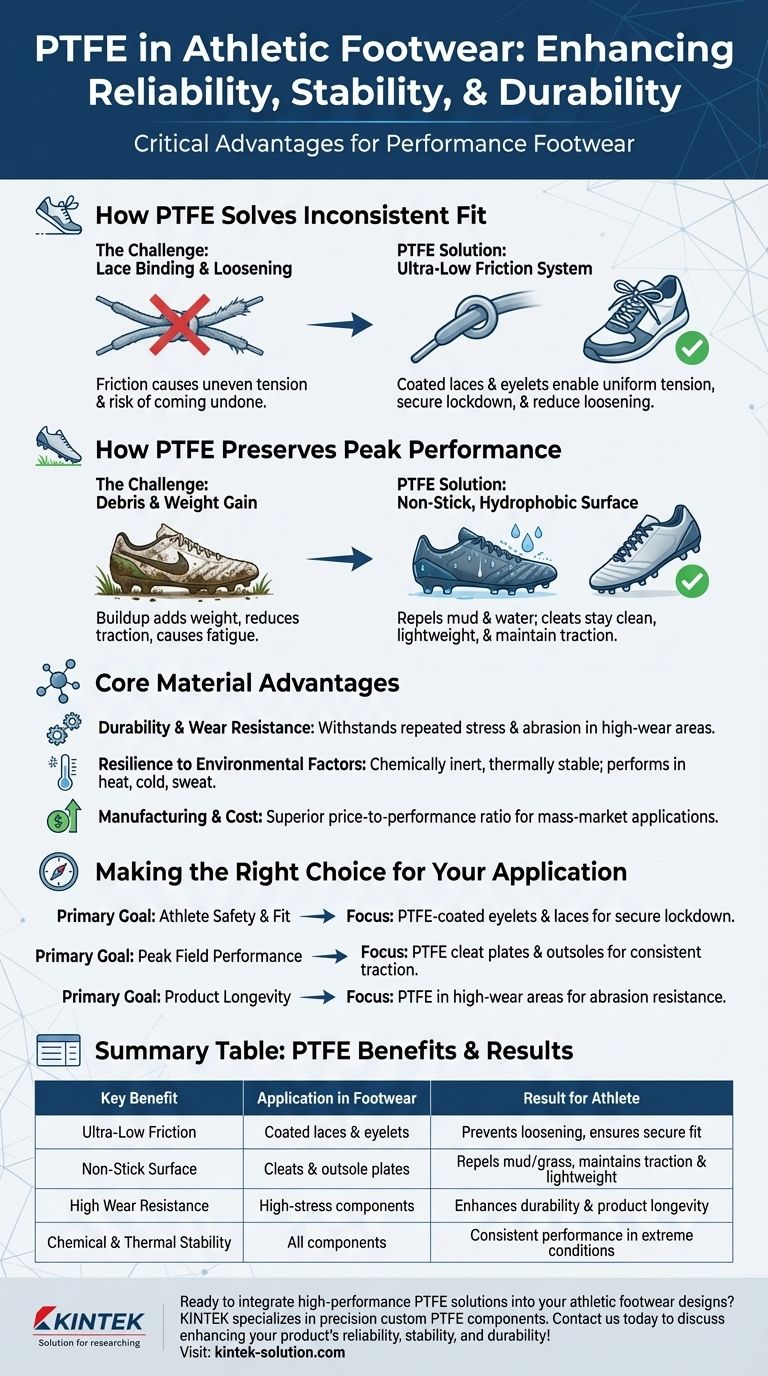

How PTFE Solves the Problem of Inconsistent Fit

The Challenge: Lace Binding and Loosening

Traditional shoelaces create significant friction as they pass through eyelets, leading to uneven tension across the foot. This can create pressure points and cause the laces to work themselves loose during intense athletic movements, increasing the risk of tripping or requiring constant readjustment.

The Solution: An Ultra-Low Friction System

PTFE has one of the lowest coefficients of friction of any known solid. When used as a coating on shoelaces and eyelets, it creates a smooth, almost effortless pull.

This allows an athlete to achieve uniform tension with a single pull, securing the foot evenly and comfortably. Most importantly, this low-friction system helps lock the laces in place, drastically reducing the chances of them coming undone during competition.

How PTFE Preserves Peak Performance on the Field

The Challenge: Debris and Weight Gain

For athletes in field sports, cleats can quickly accumulate mud, grass, and water. This buildup adds significant weight to the shoe, which can cause fatigue over the course of a game.

More critically, clogged cleats lose their ability to penetrate the ground, severely compromising traction, stability, and the athlete's ability to cut and pivot effectively.

The Solution: A Non-Stick, Hydrophobic Surface

PTFE is both hydrophobic (repels water) and oleophobic (repels oil), giving it exceptional non-stick or anti-adhesion properties.

When integrated into cleat components or applied as a surface coating on the outsole plate, PTFE actively prevents mud and grass from sticking. The cleats remain clean and functional, ensuring the shoe stays lightweight and that traction is consistent from the beginning of the game to the end.

Understanding the Material's Core Advantages

While low friction and non-stick surfaces are the primary benefits for footwear, other inherent properties of PTFE make it a robust choice for athletic applications.

Durability and Wear Resistance

PTFE exhibits high flexural strength and wear resistance. When used in eyelets or as part of a cleat structure, it withstands the repeated stress and abrasion of athletic movements, contributing to the overall longevity of the footwear.

Resilience to Environmental Factors

The material is chemically inert and possesses excellent thermal stability, with a working temperature range from below freezing to over 260°C (500°F).

This means PTFE components will not degrade from contact with sweat, cleaning agents, or exposure to extreme temperatures like hot artificial turf or cold, frozen ground. Their properties remain consistent regardless of the playing conditions.

Manufacturing and Cost

From a production standpoint, PTFE offers a superior price-to-performance ratio compared to other fluoropolymers. Its established manufacturing processes and relative affordability make it a viable material for creating high-performance features in mass-market athletic footwear.

Making the Right Choice for Your Application

When considering PTFE, it is crucial to align its properties with your primary design goal.

- If your primary focus is athlete safety and consistent fit: Prioritize PTFE-coated eyelets and laces to create a low-friction system that prevents loosening and ensures a secure lockdown.

- If your primary focus is maintaining peak field performance: Implement PTFE in cleat plates and outsole components to prevent debris buildup and guarantee consistent traction.

- If your primary focus is product longevity and durability: Use PTFE as a material or coating in high-wear areas to increase the footwear's resistance to abrasion and environmental degradation.

By understanding these core material properties, you can strategically apply PTFE to solve specific performance challenges in athletic footwear.

Summary Table:

| Key Benefit | Application in Footwear | Result for Athlete |

|---|---|---|

| Ultra-Low Friction | Coated laces & eyelets | Prevents loosening, ensures secure fit |

| Non-Stick Surface | Cleats & outsole plates | Repels mud/grass, maintains traction & lightweight |

| High Wear Resistance | High-stress components | Enhances durability & product longevity |

| Chemical & Thermal Stability | All components | Consistent performance in extreme conditions |

Ready to integrate high-performance PTFE solutions into your athletic footwear designs?

KINTEK specializes in precision manufacturing of custom PTFE components—from seals and liners to specialized coatings—for the athletic, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our expertise ensures optimal material performance for your unique applications.

Contact us today to discuss how our PTFE solutions can enhance your product's reliability, stability, and durability!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- What is the maximum working temperature for Teflon balls? Ensuring Safe and Reliable Performance

- What industrial applications utilize extruded PTFE rods? Key Uses in Chemical, Aerospace & More

- What lubrication properties do PTFE O-rings have? Low Friction and Self-Lubricating Seals

- What are PTFE O-rings and what are they commonly used for? Solve Sealing Challenges in Harsh Environments

- What is the temperature rating for PTFE gaskets? Maximize Performance from -200°C to 260°C

- What are the limitations or challenges of PTFE envelope gaskets? Manage Creep, Installation, and Thermal Expansion

- What are PTFE reducing flanges used for? Connect Pipes of Different Sizes with Superior Chemical Resistance

- What industries commonly use PTFE lined dual plate check valves? Essential for Corrosive & High-Purity Applications