At its core, Teflon (PTFE) is defined by four exceptional properties. These are an extremely low-friction, non-stick surface, a remarkable resistance to nearly all chemicals, and the ability to remain stable across a very wide range of temperatures. This unique combination makes it one of the most versatile and reliable materials for demanding environments.

The true value of Teflon sheets isn't found in a single characteristic, but in the rare combination of thermal stability, chemical inertness, and low surface energy. This allows the material to perform reliably where most other plastics and even metals would quickly fail.

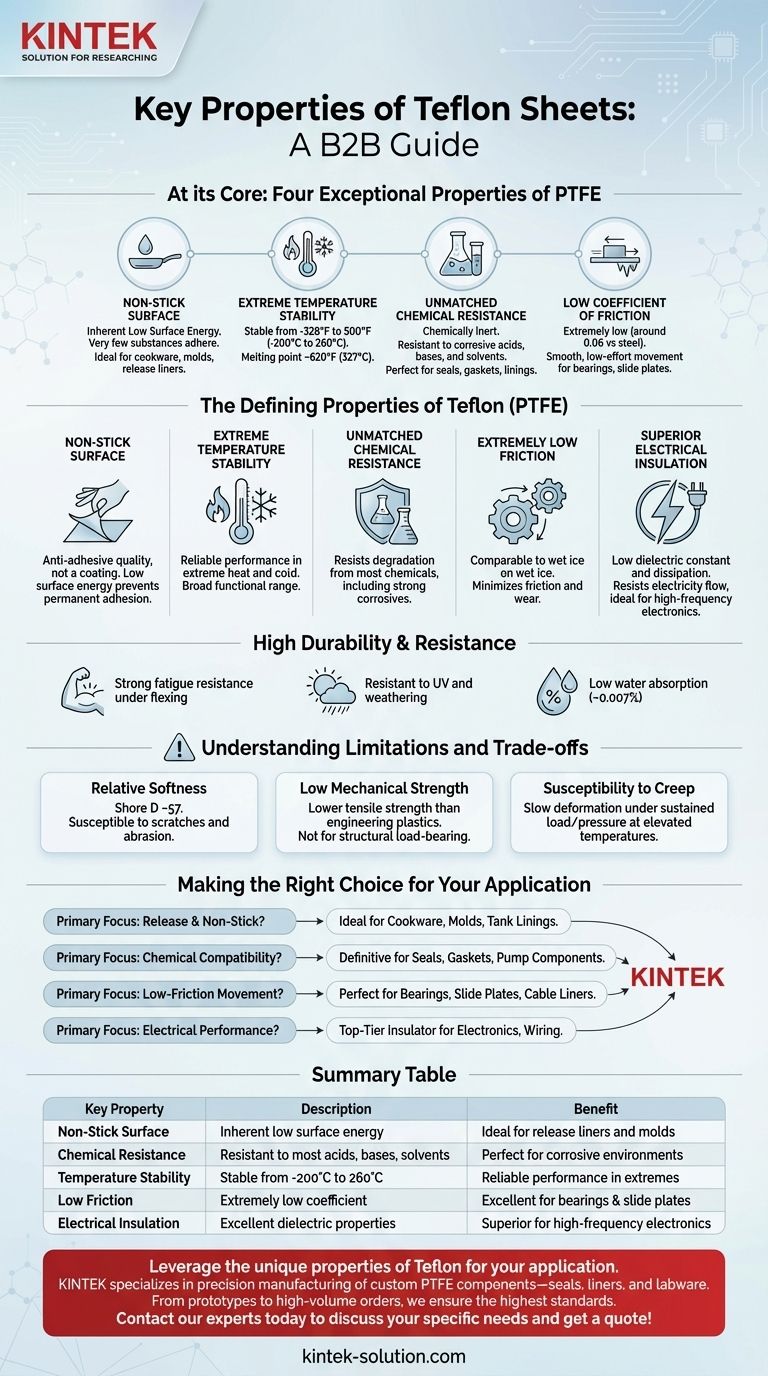

The Defining Properties of Teflon (PTFE)

Teflon is the brand name for Polytetrafluoroethylene (PTFE), a fluoropolymer with a unique molecular structure that gives rise to its sought-after characteristics. Understanding these foundational properties is key to leveraging the material effectively.

Exceptional Non-Stick Surface

Teflon is famous for its anti-adhesive or non-stick quality. This is not a coating but an inherent property of the material's low surface energy.

Very few substances will permanently adhere to a Teflon sheet, which is why it is used extensively for cookware, molds, and industrial release liners.

Extreme Temperature Stability

This material performs reliably in both extreme cold and high heat. Teflon remains stable and functional across a broad temperature range, typically from -328°F to 500°F (-200°C to 260°C).

While it can withstand high temperatures, its melting point is around 620°F (327°C), beyond which it will begin to degrade.

Unmatched Chemical Resistance

Teflon is one of the most chemically inert materials known. It is highly resistant to degradation from a wide range of corrosive substances, including strong acids and bases.

Only a few highly reactive chemicals, such as molten alkali metals, can affect its integrity. This makes it an essential material for seals, gaskets, and linings in the chemical processing industry.

Extremely Low Coefficient of Friction

Teflon possesses one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. The friction coefficient against steel is exceptionally low, around 0.06.

This property is the reason it is used for high-performance bearings, slide plates, and other mechanical applications where smooth, low-effort movement is critical.

Superior Electrical Insulation

Teflon is an excellent electrical insulator with a low dielectric constant and dissipation factor. This means it resists the flow of electricity and does not readily absorb energy from an electric field.

These electrical properties make it a superior choice for high-frequency applications, such as in coaxial cables and printed circuit boards.

High Durability and Resistance

Teflon exhibits strong fatigue resistance under repeated flexing. It is also resistant to UV radiation and weathering, allowing it to be used in outdoor applications without significant degradation.

Furthermore, it has very low water absorption (around 0.007%), ensuring its properties remain stable even in humid environments.

Understanding the Limitations and Trade-offs

No material is perfect. Acknowledging Teflon's trade-offs is critical for proper application and avoiding failure. Its unique strengths are balanced by certain inherent limitations.

Relative Softness

Teflon is a relatively soft polymer with a Shore D hardness of around 57. This makes it susceptible to scratches, abrasion, and physical damage compared to harder plastics or metals.

While it is reusable, sharp or abrasive contact can compromise the surface.

Low Mechanical Strength

Compared to engineering plastics like nylon or PEEK, Teflon has low tensile strength and structural rigidity. It is not designed to be a load-bearing structural component on its own.

Susceptibility to Creep

Under a constant, sustained load (especially at elevated temperatures), Teflon can slowly deform over time. This phenomenon, known as creep, must be considered in designs where precise dimensional stability is required under pressure.

Making the Right Choice for Your Application

To determine if Teflon is the correct material, align its core strengths with your primary goal.

- If your primary focus is release and non-stick surfaces: Teflon's inherent low surface energy makes it the ideal choice for cookware, industrial molds, and chemical tank linings.

- If your primary focus is chemical compatibility: Its near-total chemical inertness makes it the definitive material for seals, gaskets, and pump components in corrosive environments.

- If your primary focus is low-friction movement: Its incredibly low friction coefficient is perfect for self-lubricating bearings, slide plates, and cable liners requiring smooth operation.

- If your primary focus is electrical performance: Its excellent dielectric properties make it a top-tier insulator for high-frequency electronics and specialized wiring.

Ultimately, Teflon's power lies in its ability to solve problems in environments too extreme for conventional materials.

Summary Table:

| Key Property | Description | Benefit |

|---|---|---|

| Non-Stick Surface | Inherent low surface energy | Ideal for release liners and molds |

| Chemical Resistance | Resistant to most acids, bases, and solvents | Perfect for corrosive environments |

| Temperature Stability | Stable from -200°C to 260°C | Reliable performance in extreme conditions |

| Low Friction | Extremely low coefficient of friction | Excellent for bearings and slide plates |

| Electrical Insulation | Excellent dielectric properties | Superior for high-frequency electronics |

Leverage the unique properties of Teflon for your application. KINTEK specializes in the precision manufacturing of custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. From prototypes to high-volume orders, we ensure your parts meet the highest standards of performance and durability. Contact our experts today to discuss your specific needs and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials