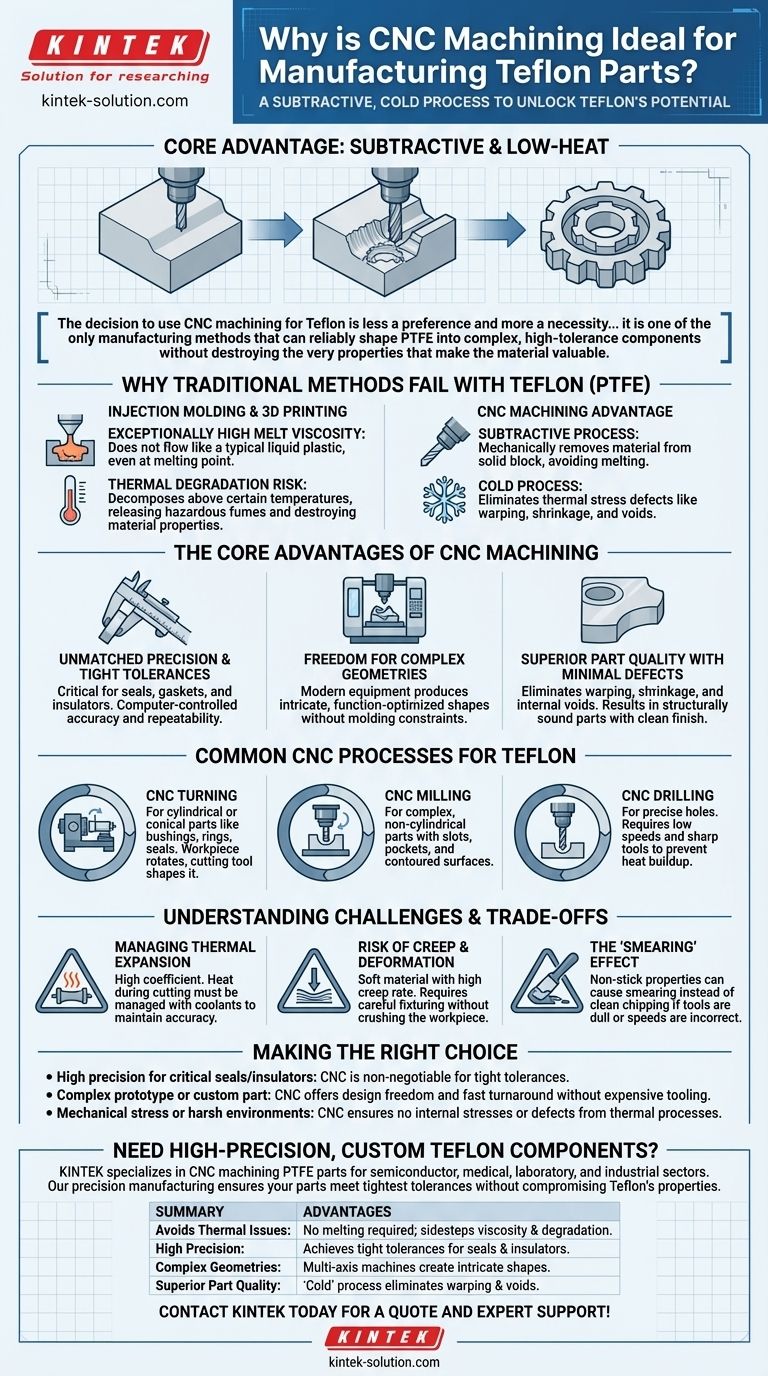

At its core, CNC machining is ideal for Teflon because it is a subtractive process that works around the material's most difficult properties. Unlike injection molding or 3D printing, CNC machining does not require melting Teflon (PTFE), thereby avoiding the challenges of its extremely high melt viscosity and risk of thermal degradation. This allows for the creation of highly precise and complex parts without compromising the material's unique chemical and thermal integrity.

The decision to use CNC machining for Teflon is less a preference and more a necessity. It is one of the only manufacturing methods that can reliably shape PTFE into complex, high-tolerance components without destroying the very properties that make the material valuable.

Why Traditional Methods Fall Short with Teflon

To understand the necessity of CNC machining, we must first look at why common polymer processing methods are unsuitable for Polytetrafluoroethylene (PTFE), the material most know as Teflon.

The Injection Molding and 3D Printing Challenge

Teflon possesses an exceptionally high melt viscosity. In practical terms, this means that even when heated to its melting point, it does not flow like a typical liquid plastic.

This poor flow characteristic makes it nearly impossible to use in processes like injection molding or 3D printing (FDM), which rely on the material flowing easily to fill a mold or be extruded through a nozzle.

The Inherent Risk of Thermal Degradation

Heating Teflon to the extreme temperatures required for molding is not only impractical but also dangerous. Above a certain threshold, PTFE begins to decompose.

This thermal degradation releases hazardous fumes and permanently damages the material's molecular structure, stripping it of its desirable non-stick, chemical-resistant, and dielectric properties. CNC machining avoids this issue entirely as it is fundamentally a mechanical, low-heat process.

The Core Advantages of CNC Machining for Teflon

By mechanically removing material from a solid block, CNC machining sidesteps Teflon's thermal limitations and unlocks several key manufacturing advantages.

Unmatched Precision and Tight Tolerances

CNC machines can achieve exceptionally tight tolerances, which is critical for performance-sensitive parts like seals, gaskets, and insulators. The computer-controlled process ensures every cut is exact, leading to superior accuracy and repeatability.

Freedom for Complex Geometries

Modern CNC equipment, especially multi-axis and 5-axis machines, can produce incredibly intricate and complex shapes. This allows engineers to design parts optimized for function without being constrained by the limitations of a molding process.

Superior Part Quality with Minimal Defects

Because CNC machining is a "cold" process, it eliminates defects associated with thermal stress, such as warping, shrinkage, and internal voids. The result is a structurally sound part with a clean, high-quality surface finish.

Common CNC Processes for Teflon Components

Different CNC operations are employed depending on the final geometry of the part. Each leverages computer control to handle Teflon's unique properties.

CNC Turning

This method is used to create cylindrical or conical components like bushings, rings, and seals. The Teflon workpiece rotates while a cutting tool shapes it, ideal for parts with rotational symmetry.

CNC Milling

Milling uses a rotating cutter to remove material from a stationary workpiece. It is essential for creating complex, non-cylindrical parts with features like slots, pockets, and contoured surfaces.

CNC Drilling

Drilling creates precise holes in the Teflon part. Machinists must use low speeds and sharp tools to prevent heat buildup and ensure a clean cut without melting or deforming the material.

Understanding the Trade-offs and Challenges

While ideal, machining Teflon is not without its challenges. An expert machinist must account for the material's unique behavior to achieve a successful outcome.

Managing Thermal Expansion

Teflon has a high coefficient of thermal expansion, meaning it expands and contracts significantly with temperature changes. Heat generated during cutting must be carefully managed with coolants and controlled cutting parameters to maintain dimensional accuracy.

The Risk of Creep and Deformation

PTFE is a soft material with a high creep rate, meaning it can slowly deform under sustained pressure. This requires careful fixturing (clamping) to hold the workpiece securely without crushing or distorting it.

The "Smearing" Effect

Teflon's famous non-stick properties can sometimes work against the machining process. If cutting tools are not exceptionally sharp or speeds are incorrect, the material can smear rather than chip away cleanly, leading to a poor surface finish.

Making the Right Choice for Your Application

Selecting CNC machining for your Teflon part is often the only viable path, but understanding why empowers you to specify the right requirements for your project.

- If your primary focus is high precision for critical seals or insulators: CNC machining is non-negotiable, as it is the only way to reliably hold the tight tolerances required for proper performance.

- If you are developing a complex prototype or custom part: The design freedom and lack of expensive tooling make CNC the fastest and most effective method for creating intricate geometries.

- If your part must withstand mechanical stress or harsh chemical environments: CNC machining ensures the part has no internal stresses or defects from a thermal process, maximizing its structural integrity and chemical resistance.

Ultimately, leveraging CNC machining allows you to harness the full potential of Teflon's remarkable properties in your final component.

Summary Table:

| Advantage | Description |

|---|---|

| Avoids Thermal Issues | No melting required; sidesteps high melt viscosity and degradation risk. |

| High Precision | Achieves tight tolerances critical for seals, gaskets, and insulators. |

| Complex Geometries | Multi-axis machines create intricate shapes not possible with molding. |

| Superior Part Quality | "Cold" process eliminates warping, shrinkage, and internal voids. |

Need high-precision, custom Teflon components?

KINTEK specializes in CNC machining PTFE parts for the semiconductor, medical, laboratory, and industrial sectors. Our precision manufacturing ensures your parts meet the tightest tolerances without compromising Teflon's unique chemical and thermal properties.

We offer custom fabrication from prototypes to high-volume orders. Let us help you harness the full potential of Teflon in your application.

Contact KINTEK today for a quote and expert manufacturing support!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications