In high-speed applications, PTFE rotary shaft seals excel where conventional elastomeric seals fail. Their outstanding performance is directly tied to an inherently low coefficient of friction, which allows them to handle shaft surface speeds up to 35 m/s. This characteristic minimizes frictional heat generation, the primary cause of seal degradation and premature failure in high-velocity rotating equipment.

The critical challenge in high-speed sealing is not the speed itself, but the destructive heat generated by friction. PTFE's unique, self-lubricating nature directly counters this issue, enabling it to maintain seal integrity and longevity under conditions that would cause other materials to rapidly fail.

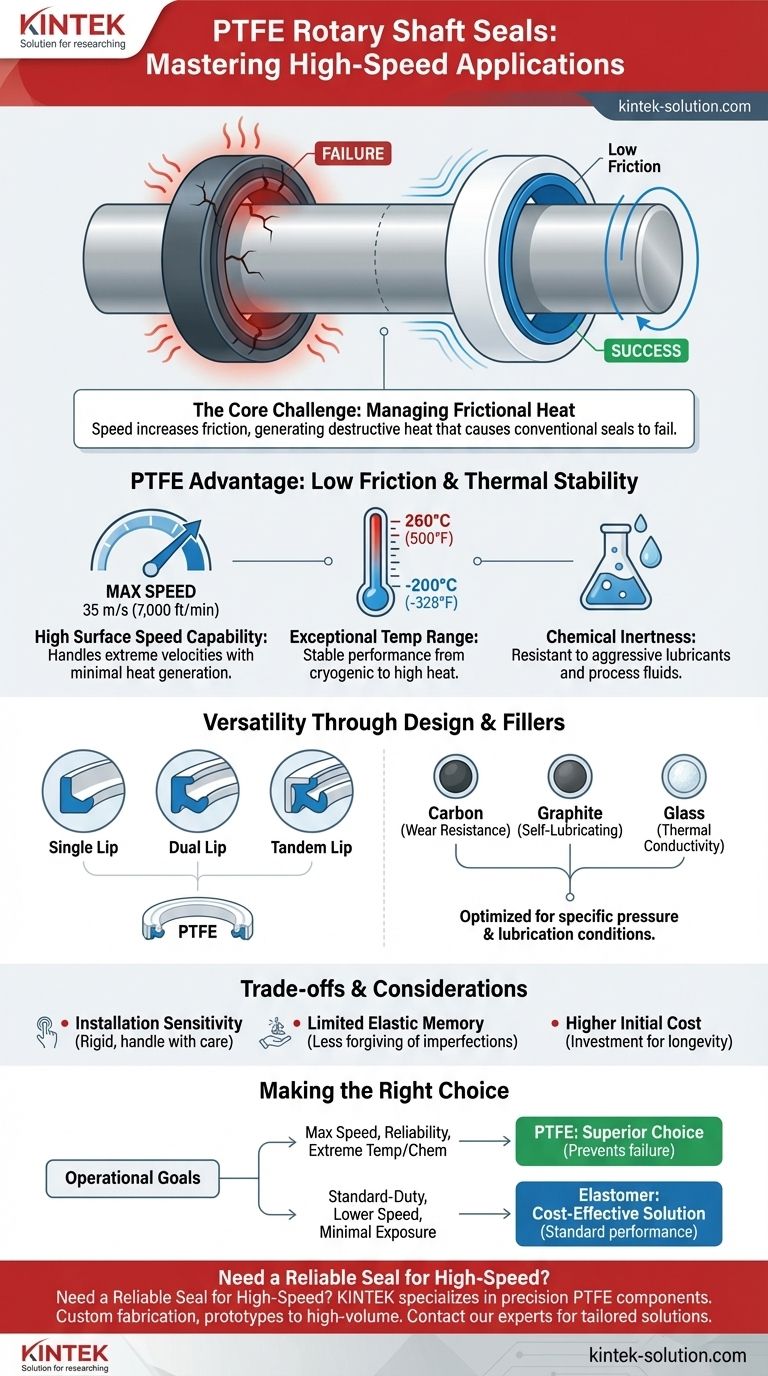

The Core Principle: Managing Frictional Heat

High-speed rotation creates a challenging environment for any sealing element. The performance of a seal is fundamentally limited by its ability to manage the heat generated at the contact point between the seal lip and the rotating shaft.

The Problem with High Rotational Speeds

As shaft speed increases, friction generates heat at an accelerated rate. In traditional elastomer seals, this heat can cause the material to harden, crack, or lose its sealing properties, leading to leaks and costly downtime.

How PTFE Solves the Heat Problem

PTFE (Polytetrafluoroethylene) possesses an extremely low coefficient of friction, one of the lowest of any solid material. This "self-lubricating" property means less energy is converted into heat at the sealing lip.

By generating significantly less heat, a PTFE seal can operate at much higher speeds without reaching a critical failure temperature.

Exceptional Thermal Stability

Beyond just generating less heat, PTFE has a remarkably wide operating temperature range, from -200°C (-328°F) up to 260°C (500°F). This provides a substantial safety margin, ensuring the seal material remains stable even under demanding high-speed conditions.

Key Attributes Supporting High-Speed Performance

While managing heat is the primary factor, several other characteristics of PTFE contribute to its success in high-speed applications.

High Surface Speed Capability

Engineered PTFE seals are validated to perform reliably at continuous shaft surface speeds of up to 35 m/s (approximately 7,000 ft/min). This is significantly higher than the typical limits for many standard rubber seals.

Chemical Inertness

High-speed applications often involve aggressive synthetic lubricants or process fluids. PTFE is virtually inert to all acids, bases, solvents, and oils, ensuring that chemical attack will not compromise seal integrity, even at elevated temperatures.

Versatility Through Design and Fillers

The performance of a PTFE seal is not based on the material alone. The design of the seal lip (single lip, dual lip, tandem lip) can be optimized for specific pressure and lubrication conditions.

Furthermore, fillers such as carbon, graphite, or glass can be blended with the base PTFE to enhance specific properties like wear resistance and thermal conductivity, further improving performance in extreme applications.

Understanding the Trade-offs and Considerations

While highly effective, PTFE seals are not a universal solution. An objective analysis requires understanding their specific limitations.

Installation Sensitivity

PTFE seals are more rigid than their elastomeric counterparts. They have less elasticity, meaning they must be handled and installed with greater care to avoid nicking or deforming the precision-engineered sealing lip.

Limited Elastic "Memory"

Unlike rubber, PTFE does not rebound as effectively after being deformed. This makes it less forgiving of imperfections in the shaft or housing, such as significant runout or misalignment, which can compromise the sealing contact.

Cost Factor

High-performance PTFE seals, particularly those with specialized fillers and complex designs, typically represent a higher initial investment compared to standard nitrile or Viton seals. This cost must be weighed against the benefits of longer service life and reduced maintenance in demanding applications.

Making the Right Choice for Your Application

Selecting the correct seal requires matching the material's capabilities to the operational goals of your machinery.

- If your primary focus is maximum rotational speed and reliability: PTFE is the superior choice due to its low-friction properties and ability to manage heat, preventing premature failure.

- If your application involves extreme temperatures or aggressive chemicals: PTFE's exceptional thermal stability and chemical inertness make it the only viable option in many cases.

- If your application is a standard-duty, lower-speed environment with minimal chemical exposure: A conventional elastomeric seal may provide a more cost-effective solution, as the advanced properties of PTFE would be underutilized.

Ultimately, understanding that PTFE's value lies in its ability to solve the core problem of frictional heat is the key to making an informed engineering decision.

Summary Table:

| Performance Attribute | PTFE Seal Capability |

|---|---|

| Max Surface Speed | Up to 35 m/s (7,000 ft/min) |

| Operating Temperature | -200°C to 260°C (-328°F to 500°F) |

| Key Advantage | Extremely low friction minimizes heat generation |

| Chemical Resistance | Excellent resistance to acids, bases, oils, and solvents |

Need a reliable seal for your high-speed application?

KINTEK specializes in manufacturing precision PTFE components, including custom rotary shaft seals, for the semiconductor, medical, laboratory, and industrial sectors. Our seals are engineered to deliver unmatched performance in high-speed, high-temperature, and chemically aggressive environments, preventing costly downtime.

We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit and optimal performance for your specific requirements.

Contact our experts today to discuss your sealing challenge and receive a tailored solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials