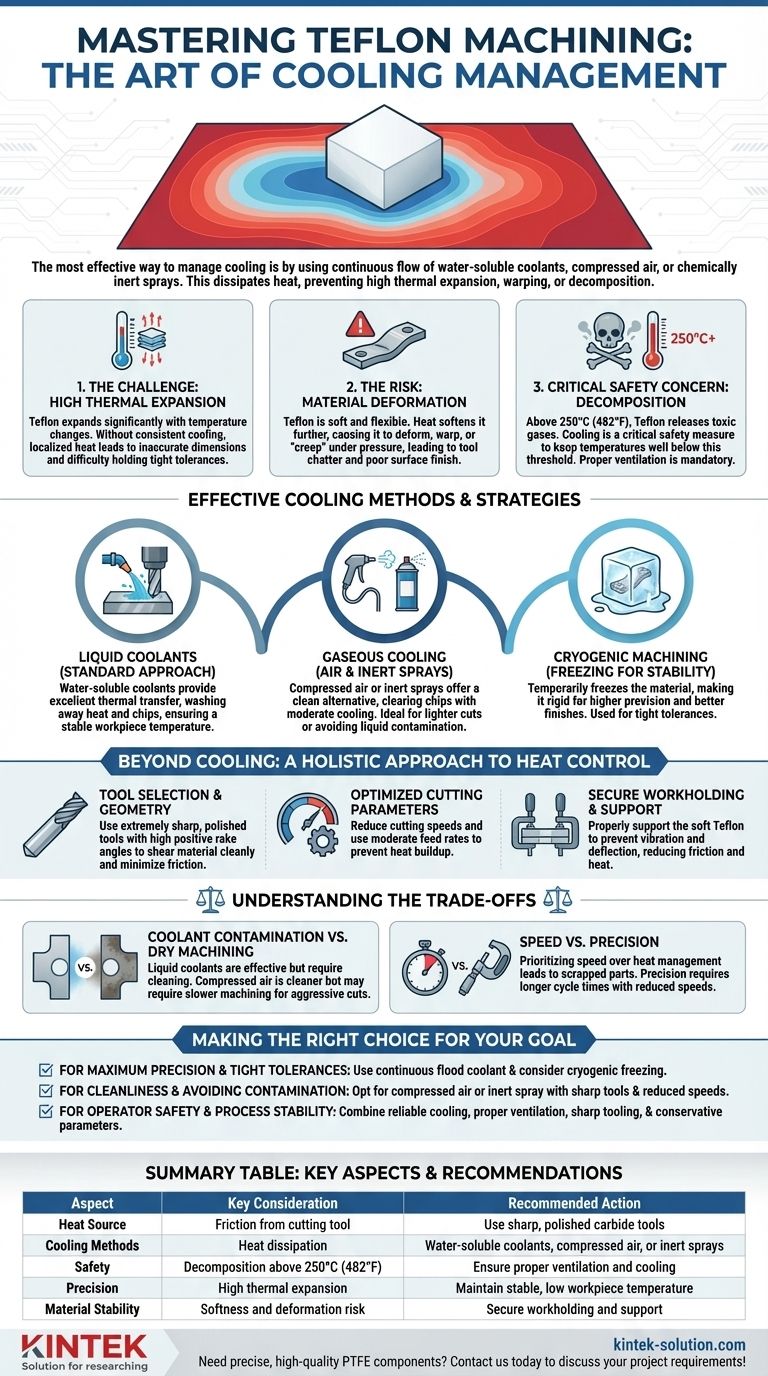

The most effective way to manage cooling during Teflon machining is by using a continuous flow of water-soluble coolants, compressed air, or chemically inert sprays. These methods are essential for dissipating heat generated at the cutting edge, which prevents the material's high thermal expansion from compromising dimensional accuracy and stops it from warping or decomposing under high temperatures.

The core challenge in machining Teflon (PTFE) is not the cutting itself, but managing the heat it generates. Effective cooling is one part of a broader heat control strategy required to overcome the material's inherent softness, high thermal expansion, and low melting point.

Why Heat Management is Critical for Teflon

Understanding the properties of Teflon reveals why controlling temperature is the primary factor for success. Heat is the direct cause of the most common machining failures.

The Challenge of High Thermal Expansion

Teflon has a very high coefficient of thermal expansion, meaning it expands and contracts significantly with even minor temperature changes.

Without consistent cooling, localized heat from the cutting tool will cause the material to expand, leading to inaccurate dimensions once it cools back to ambient temperature.

This makes holding tight tolerances exceptionally difficult if the workpiece temperature is not kept stable and low.

The Risk of Material Deformation

Teflon is a very soft and flexible material. When combined with heat, its tendency to deform, warp, or "creep" under pressure is amplified.

Heat softens the material further, making it prone to being pushed away by the tool rather than being cleanly cut. This can also lead to tool chatter and a poor surface finish.

Proper cooling helps maintain the material's rigidity, ensuring a cleaner and more precise cut.

The Critical Safety Concern: Decomposition

This is the most important consideration. Above 250°C (482°F), Teflon begins to decompose, releasing toxic and corrosive gases.

Effective cooling, combined with appropriate speeds and feeds, is a critical safety measure to keep cutting temperatures well below this threshold. Proper ventilation is always mandatory when machining Teflon for this reason.

Effective Cooling Methods and Strategies

The right cooling method depends on the specific application, but all aim to remove heat directly from the cutting zone.

Liquid Coolants: The Standard Approach

Water-soluble coolants are the most common and effective method for managing heat during Teflon machining.

They provide excellent thermal transfer, continuously washing away heat and chips from the cutting area. This ensures a stable workpiece temperature.

Gaseous Cooling: Air and Inert Sprays

Compressed air offers a clean alternative that can be sufficient for lighter cuts. It helps clear chips and provides a moderate cooling effect without contaminating the workpiece.

For more demanding applications, chemically inert sprays can provide superior cooling without the mess of liquid coolants.

Cryogenic Machining: Freezing for Stability

An advanced but highly effective technique involves temporarily freezing the material before and during machining.

This makes the Teflon much more rigid and less prone to deformation, allowing for higher precision and better surface finishes. It is typically reserved for parts with extremely tight tolerances.

Beyond Cooling: A Holistic Approach to Heat Control

Cooling is a reactive measure. A truly effective strategy also involves proactively minimizing the amount of heat generated in the first place.

Tool Selection and Geometry

The primary source of heat is friction. Use extremely sharp tools, preferably made from cemented carbide, with highly polished surfaces to minimize this friction.

Tools with high positive rake angles and significant relief angles will shear the material cleanly rather than plowing through it, further reducing heat and cutting forces.

Optimized Cutting Parameters

High cutting speeds generate excessive heat. It is crucial to reduce cutting speeds and use a moderate feed rate.

The goal is to create a clean chip without allowing heat to build up in the tool or the workpiece.

Secure Workholding and Support

Because Teflon is so soft, it must be properly supported to prevent it from vibrating or deflecting under cutting pressure.

A secure clamping method prevents movement that can lead to inaccurate cuts and increased friction, which in turn generates more heat.

Understanding the Trade-offs

Choosing the right approach requires balancing competing factors like cleanliness, efficiency, and cost.

Coolant Contamination vs. Dry Machining

While liquid coolants are highly effective, they can contaminate the workpiece, requiring a post-machining cleaning process.

Using compressed air avoids this issue but may provide insufficient cooling for aggressive cuts, forcing you to use slower machining parameters.

Speed vs. Precision

The measures required to control heat—namely, reduced cutting speeds—will inherently result in longer cycle times.

Attempting to prioritize speed over heat management will almost always lead to scrapped parts due to dimensional inaccuracies or warping. Precision must be the primary focus.

Making the Right Choice for Your Goal

Your primary objective will determine the best combination of cooling and heat management strategies.

- If your primary focus is maximum precision and tight tolerances: Use a continuous flood of water-soluble coolant and consider cryogenic freezing for the most critical features.

- If your primary focus is cleanliness and avoiding contamination: Opt for compressed air or an inert gas spray, but compensate with very sharp tools and reduced cutting speeds.

- If your primary focus is operator safety and process stability: Combine a reliable cooling system with proper ventilation and prioritize sharp tooling and conservative cutting parameters above all else.

Ultimately, successful Teflon machining is achieved by treating heat as the primary adversary and deploying a comprehensive strategy to control it.

Summary Table:

| Aspect | Key Consideration | Recommended Action |

|---|---|---|

| Heat Source | Friction from cutting tool | Use sharp, polished carbide tools |

| Cooling Methods | Heat dissipation | Water-soluble coolants, compressed air, or inert sprays |

| Safety | Decomposition above 250°C (482°F) | Ensure proper ventilation and cooling |

| Precision | High thermal expansion | Maintain stable, low workpiece temperature |

| Material Stability | Softness and deformation risk | Secure workholding and support |

Need precise, high-quality PTFE components? At KINTEK, we specialize in machining Teflon with advanced cooling strategies to ensure dimensional accuracy, prevent warping, and maintain material integrity. Whether you require custom prototypes or high-volume orders for the semiconductor, medical, laboratory, or industrial sectors, our expertise in precision production delivers reliable results. Contact us today to discuss your project requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key properties of PTFE washers? Ensure Reliability in Extreme Environments

- What makes Expanded PTFE gaskets ideal for uneven surfaces? Achieve a Perfect Seal on Imperfect Flanges

- What are the limitations of PTFE O-rings' media resistance? Avoid Common Application Traps

- Which contact surfaces provide the best wear resistance for PTFE piston rings? Design a High-Performance System

- What are recommended tolerances for machining PTFE parts? Achieve Dimensional Stability & Cost-Effectiveness

- What is the best choice for thinner dielectric layers in PTFE-based materials? Ceramic-Filled Composites for High-Frequency Stability

- What are important final considerations when machining Teflon? Mastering PTFE for Precision and Safety

- What are the physical properties of PTFE balls? A Guide to Extreme Chemical & Thermal Performance