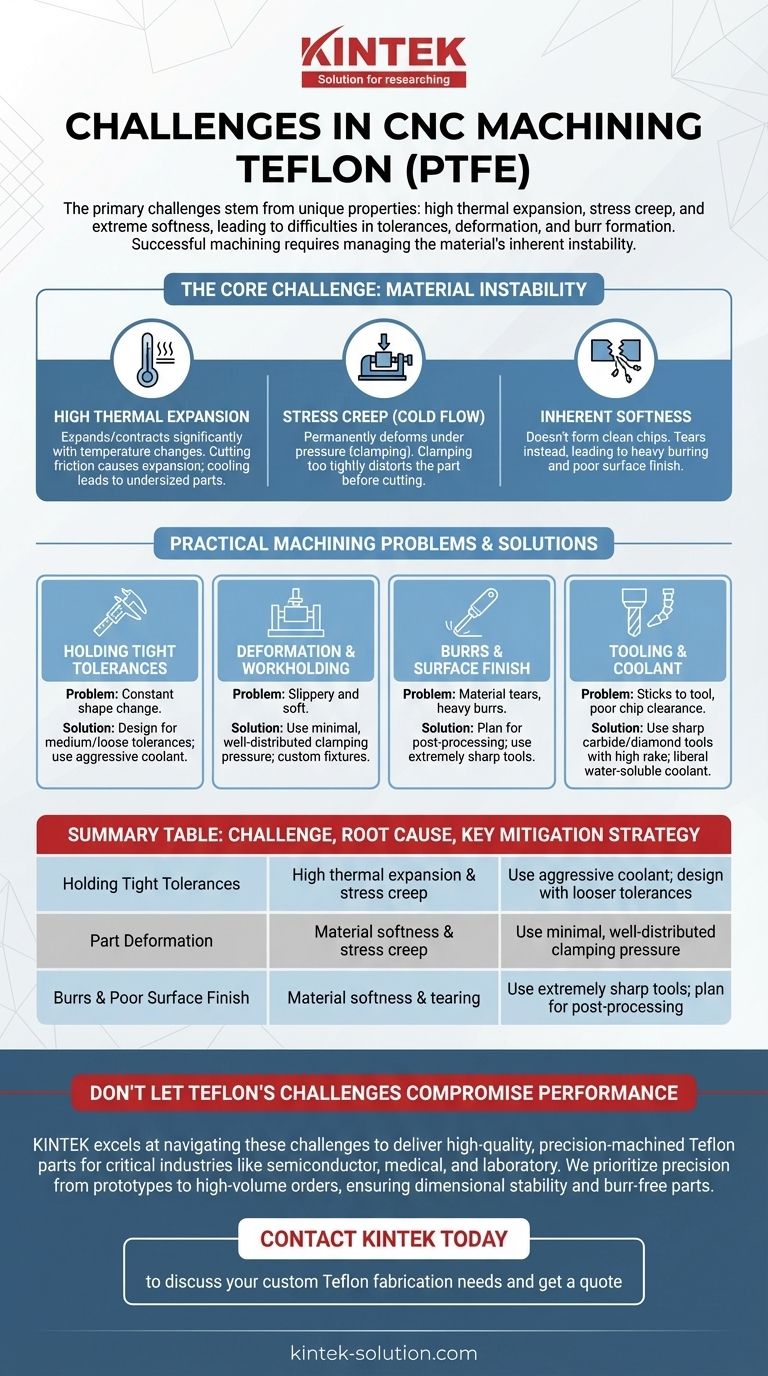

The primary challenges in CNC machining Teflon stem from its unique combination of material properties: high thermal expansion, a tendency to deform under pressure (stress creep), and extreme softness. These factors make it difficult to achieve tight tolerances, prevent deformation during clamping, and avoid the formation of burrs that require post-processing.

The core issue is that the very properties that make Teflon desirable—its low friction and chemical inertness—also make it dimensionally unstable. Successful machining is less about forcing precision and more about understanding and mitigating the material's inherent tendency to move and deform.

The Core Challenge: Material Instability

Teflon (PTFE) is not a rigid, stable material like aluminum or steel. Its behavior during machining is dictated by three key properties that you must account for at every stage of the process.

High Thermal Expansion

Teflon has a very high coefficient of thermal expansion. This means it expands and contracts significantly with even minor changes in temperature.

The friction from a cutting tool generates heat, causing the material to expand while being cut. As it cools, it will shrink, meaning the final part may be smaller than your intended dimensions.

Stress Creep (Cold Flow)

Teflon is known for "stress creep," or cold flow. When subjected to pressure—even moderate clamping force—the material will slowly and permanently deform over time.

This makes workholding a significant challenge. Clamping a part too tightly will distort it, compromising accuracy before the first cut is even made.

Inherent Softness

Teflon is an exceptionally soft material. This softness is the root cause of several downstream machining problems.

It doesn't form clean "chips" like metal does. Instead, it tears, leading to heavy burring and often a poor surface finish that requires secondary operations to clean up.

Practical Machining Problems and Solutions

Understanding the material's properties helps explain the specific issues you will face on the machine and how to approach them.

Difficulty Holding Tight Tolerances

Achieving tight, repeatable tolerances is the single greatest challenge. The combination of thermal expansion and stress creep means the part is constantly changing shape.

For this reason, it's best to design parts with medium-to-loose tolerances whenever possible. Fighting the material's nature is a recipe for frustration and scrapped parts.

Deformation and Workholding

Teflon's low coefficient of friction makes it slippery, while its softness makes it easy to crush. This creates a difficult workholding scenario.

You must secure the part firmly enough to resist cutting forces without applying so much pressure that you deform it. This often requires custom fixtures or a delicate touch with standard vises.

Managing Burrs and Surface Finish

Due to its softness, Teflon rarely cuts cleanly. It produces stringy chips and leaves significant burrs along cut edges.

A deburring strategy should be part of the initial plan, not an afterthought. Post-processing techniques like light sanding or even freezing the part to make it more brittle can help in removing burrs cleanly.

Selecting the Right Tooling and Coolant

Standard cutting tools can struggle with Teflon. The material's softness can cause it to stick to the tool, and improper geometry can exacerbate burring.

Use extremely sharp cutting tools, ideally custom-ground carbide or diamond cutters with high positive rake angles and relief to improve chip clearance. A liberal application of water-soluble coolant is also critical to wash away chips and, most importantly, manage heat.

Understanding the Trade-offs

Machining Teflon effectively means accepting certain compromises that you wouldn't with other materials.

Precision vs. Material Choice

Teflon is not the material for highly precise, dimensionally critical components. Its instability is a fundamental limitation. If your application demands +/- 0.001" tolerances, you should critically evaluate if Teflon is the right choice.

The Necessity of Post-Processing

A perfect, burr-free part straight off the machine is highly unlikely. Factoring in time and labor for manual deburring and finishing is a realistic part of quoting and planning any Teflon job.

The Impact on Cycle Time

To manage heat and cutting forces, you often need to adjust machining parameters. This may involve slower feed rates or shallower depths of cut, which can increase overall cycle time compared to machining more rigid plastics or metals.

How to Apply This to Your Project

Your strategy for machining Teflon should be dictated by your primary goal for the finished component.

- If your primary focus is dimensional accuracy: Design the part with the most generous tolerances the application will allow and use coolant aggressively to minimize thermal expansion.

- If your primary focus is surface finish: Plan for a mandatory post-processing step and use exceptionally sharp tooling to minimize burr formation from the start.

- If your primary focus is preventing deformation: Develop a workholding strategy that supports the part securely with minimal clamping pressure, and reduce cutting forces by taking lighter cuts.

Ultimately, successfully machining Teflon comes from respecting the material's limitations rather than trying to overcome them.

Summary Table:

| Challenge | Root Cause | Key Mitigation Strategy |

|---|---|---|

| Holding Tight Tolerances | High thermal expansion & stress creep | Use aggressive coolant; design with looser tolerances |

| Part Deformation | Material softness & stress creep | Use minimal, well-distributed clamping pressure |

| Burrs & Poor Surface Finish | Material softness & tearing | Use extremely sharp tools; plan for post-processing |

| Tooling Issues | Material sticks to tool; poor chip clearance | Use sharp carbide/diamond tools with high rake angles |

Don't Let Teflon's Challenges Compromise Your Component's Performance

Machining PTFE components that meet exact specifications requires specialized expertise and a deep understanding of the material's behavior. KINTEK excels at navigating these challenges to deliver high-quality, precision-machined Teflon parts.

We manufacture critical PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, and laboratory industries. Our process prioritizes precision production, from initial prototypes to high-volume orders, ensuring your parts are dimensionally stable and burr-free.

Let us put our expertise to work for you. Contact KINTEK today to discuss your custom Teflon fabrication needs and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech