In modern engineering, the material replacing carbon in critical components like seals and piston rings is Polytetrafluoroethylene, commonly known as PTFE. This shift is driven by PTFE's superior durability, significantly longer operating life, and its remarkable ability to perform reliably across a wide spectrum of pressures, velocities, and temperatures where traditional carbon-based materials falter.

The core reason for this transition is a fundamental upgrade in material science. Engineers are moving away from the inherent brittleness and operational limits of carbon to the flexible, low-friction, and chemically inert nature of PTFE, resulting in more robust and reliable mechanical systems.

The Traditional Choice: Understanding Carbon's Role

For many years, carbon-graphite materials were a standard choice for sealing applications, particularly in compressors and turbines. This was due to a few key properties that made them suitable for the demands of the time.

Carbon's Self-Lubricating Properties

The primary advantage of carbon was its ability to run dry. Its graphitic nature provided a degree of self-lubrication, reducing friction and heat in systems where liquid lubrication was impractical or undesirable.

The Inherent Limitations of Brittleness

However, carbon's main drawback is its structure. It is a brittle material, meaning it is susceptible to chipping and cracking under mechanical shock, vibration, or thermal stress. This fragility limits its lifespan and introduces a risk of catastrophic failure.

Why PTFE is a Superior Alternative

The introduction of high-performance polymers like PTFE provided a solution to the fundamental weaknesses of carbon. PTFE's molecular structure gives it a combination of properties that make it exceptionally well-suited for dynamic sealing applications.

Exceptional Durability and Wear Resistance

Unlike brittle carbon, PTFE is a resilient polymer. It can absorb impacts and vibrations without fracturing, leading to a significant increase in overall durability and resistance to wear and tear.

This resilience directly translates into a lower risk of sudden component failure, improving the safety and reliability of the entire machine.

Extended Operating Life

PTFE exhibits one of the lowest coefficients of friction of any solid material. This "slipperiness" drastically reduces the energy lost to friction and the heat generated at the sealing surface, which are primary drivers of wear.

Less friction and wear mean that PTFE seals and rings last substantially longer than their carbon counterparts, reducing maintenance frequency and operational costs.

Unmatched Operational Versatility

PTFE's stable chemical structure allows it to perform consistently across an impressive range of conditions. It is virtually inert to most industrial chemicals and solvents.

Furthermore, it maintains its integrity and performance characteristics over a broad temperature range and at various pressures and surface speeds, making it a "one-size-fits-many" solution for diverse engineering challenges.

Understanding the Material Trade-offs

No material choice is without its considerations. While PTFE offers clear advantages, understanding the trade-offs compared to carbon is essential for proper application design.

The Downside of Carbon: Fracture Risk

The key trade-off with carbon is its brittleness. While it has good thermal stability, its inability to handle shock or slight misalignments means that any operational anomaly can lead to a complete failure of the seal or ring.

Potential Considerations for PTFE: Cold Flow

The primary trade-off for PTFE is its susceptibility to "creep" or "cold flow," where the material can slowly deform over time under a constant load. This is managed by using filled grades of PTFE, where materials like glass fiber, bronze, or carbon itself are added to enhance compressive strength and reduce creep.

Making the Right Choice for Your Application

Selecting between these materials depends entirely on the operational demands and priorities of your system.

- If your primary focus is maximum reliability and service life: PTFE is the definitive choice due to its superior durability and wear resistance.

- If your application involves high vibration or risk of mechanical shock: PTFE's resilience makes it a much safer and more reliable option than brittle carbon.

- If your system operates with aggressive chemicals or across wide temperature swings: PTFE's chemical inertness and thermal stability provide a performance margin that carbon cannot match.

Ultimately, choosing PTFE is an investment in the long-term robustness and efficiency of your mechanical system.

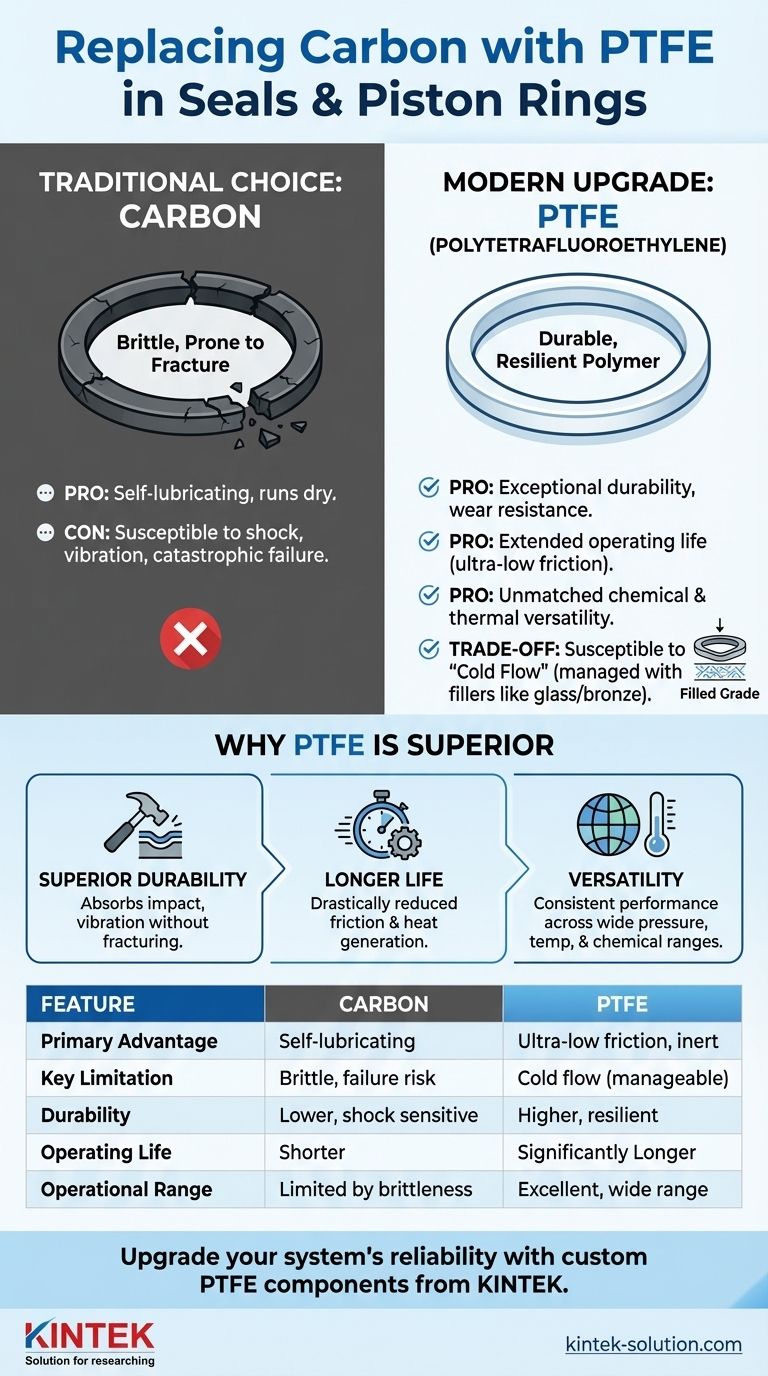

Summary Table:

| Feature | Carbon | PTFE |

|---|---|---|

| Primary Advantage | Self-lubricating, runs dry | Extremely low friction, chemical inertness |

| Key Limitation | Brittle, prone to chipping/cracking | Susceptible to cold flow (managed with fillers) |

| Durability | Lower; sensitive to shock/vibration | Higher; resilient and impact-resistant |

| Operating Life | Shorter due to wear and fracture risk | Significantly longer due to low wear |

| Operational Range | Limited by brittleness | Excellent across wide temp, pressure, & chemical ranges |

Upgrade your system's reliability and efficiency with high-performance PTFE components from KINTEK.

As detailed in this article, PTFE offers unparalleled durability and a longer operational life compared to traditional carbon, making it the ideal choice for demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

KINTEK specializes in the precision manufacturing of custom PTFE components—including seals, liners, and labware—from prototypes to high-volume orders. Our expertise ensures you get parts engineered to resist wear, chemicals, and extreme conditions, minimizing downtime and maintenance costs.

Contact KINTEK today to discuss your specific requirements and discover how our custom PTFE solutions can enhance your project's performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications