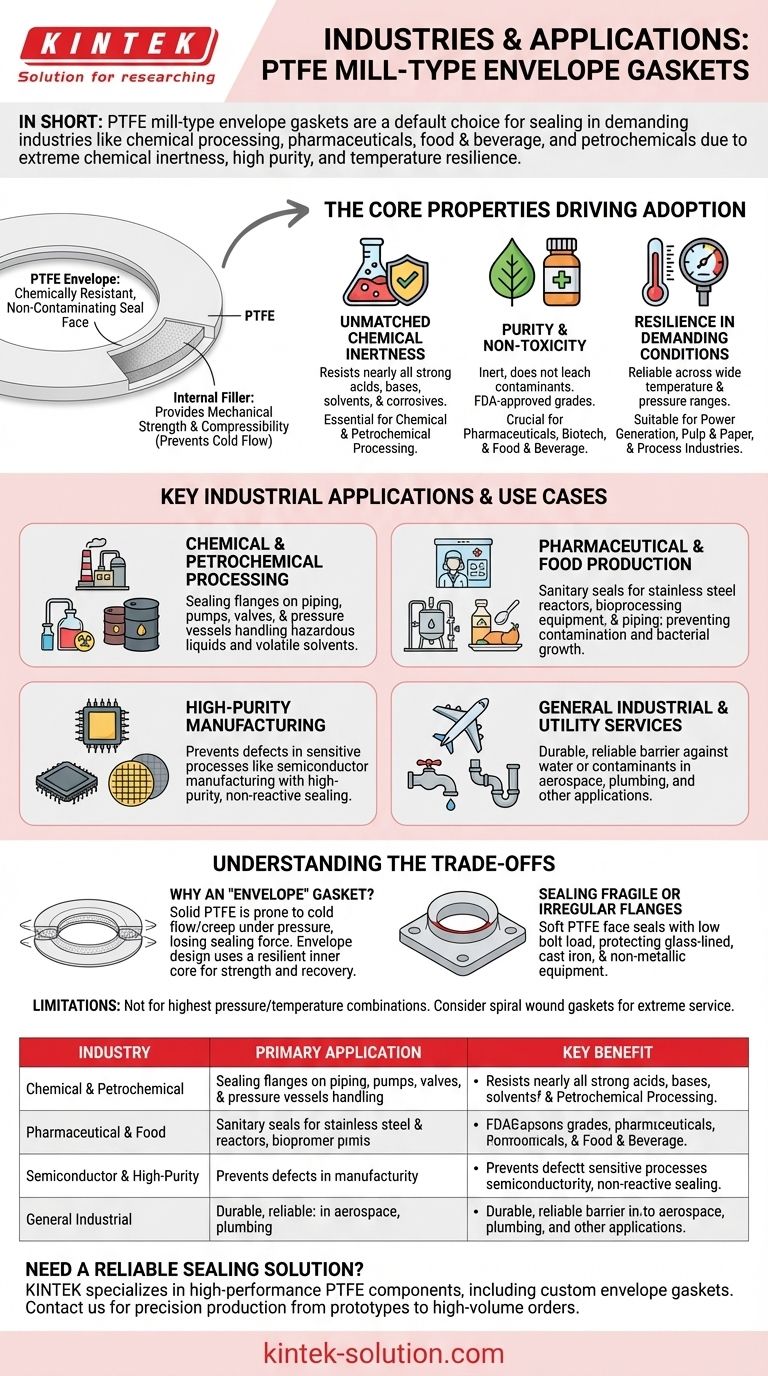

In short, PTFE mill-type envelope gaskets are applied across a wide range of demanding industries, most notably in chemical processing, pharmaceuticals, food and beverage, and petrochemicals. Their prevalence stems from a unique combination of extreme chemical inertness, high-purity characteristics, and resilience to temperature, making them a default choice for sealing flanges where corrosion or contamination would lead to critical failure.

The core reason for their widespread use is not just one feature, but the synthesis of two: the PTFE "envelope" provides a nearly universal chemically resistant and non-contaminating seal face, while an internal filler material provides the mechanical strength and compressibility that pure PTFE lacks.

The Core Properties Driving Adoption

The selection of a PTFE envelope gasket is almost always driven by the need to solve a specific set of environmental challenges. These gaskets are not a general-purpose solution but a specialized tool for critical applications.

Unmatched Chemical Inertness

The defining characteristic of PTFE is its resistance to nearly all industrial chemicals. It is exceptionally non-reactive and can handle a vast range of strong acids, bases, solvents, and corrosive substances.

This makes it indispensable in chemical and petrochemical processing, where aggressive media must be safely contained within piping systems, reactors, and pressure vessels.

Purity and Non-Toxicity

For many industries, what a gasket doesn't do is as important as what it does. PTFE is an inert, non-toxic polymer that does not leach contaminants into the process media.

This property is non-negotiable in pharmaceuticals, biotechnology, and food and beverage production. Many grades of PTFE are FDA-approved for food contact, ensuring the integrity and safety of the end product.

Resilience in Demanding Conditions

While not its primary strength compared to metallic gaskets, PTFE performs reliably across a significant range of temperatures and pressures. This stability is crucial for consistent sealing performance.

This makes it suitable for applications in power generation, pulp and paper manufacturing, and various process industries where both chemical exposure and moderate thermal cycling occur.

Key Industrial Applications and Use Cases

Understanding where these gaskets are used highlights the problems they are designed to solve. They are most often found sealing flanges in critical piping systems and equipment.

Chemical and Petrochemical Processing

In these environments, gaskets are the first line of defense against hazardous leaks. PTFE envelope gaskets are used to seal flanges on piping, pumps, valves, and pressure vessels handling everything from crude oil derivatives to volatile solvents.

Pharmaceutical and Food Production

Sanitary conditions are paramount. Here, PTFE envelope gaskets provide a clean, non-absorbent, and sterilizable seal for stainless steel reactors, bioprocessing equipment, and piping systems, preventing both product contamination and bacterial growth.

High-Purity Manufacturing

Industries like semiconductor manufacturing require extreme cleanliness to prevent defects. The high-purity and non-reactive nature of PTFE ensures that the gasket itself does not become a source of contamination in sensitive processes.

General Industrial and Utility Services

Beyond the most demanding fields, these gaskets see use in a variety of applications, including aerospace and plumbing. In any situation that requires a durable, reliable barrier against water or other liquid contaminants, especially when sealing against large openings, they are an effective choice.

Understanding the Trade-offs

No single solution is perfect for every problem. True expertise lies in knowing not just where to use a component, but also in understanding its design intent and limitations.

Why an "Envelope" Gasket?

A solid PTFE gasket would be chemically resistant but would also be prone to "cold flow," or creep, where the material deforms permanently under pressure, eventually leading to a loss of sealing force.

The envelope design solves this. The thin PTFE outer layer handles the chemical contact, while a more resilient inner core material (like non-asbestos fiber or rubber) provides the mechanical strength, compressibility, and recovery needed to maintain a tight seal over time.

Sealing Fragile or Irregular Flanges

The composite nature of the envelope gasket makes it uniquely suited for difficult sealing surfaces. The soft, conformable PTFE face creates an excellent seal without excessive bolt load.

This is critical for protecting fragile or easily damaged flange surfaces, such as those found on glass-lined, cast iron, and some non-metallic equipment.

Limitations to Consider

While the envelope design greatly improves mechanical performance over solid PTFE, it is not intended for the highest pressure and temperature combinations. In extreme service conditions, such as those found in high-pressure steam or hydrocarbon applications, a spiral wound gasket with a PTFE filler may be a more robust choice.

Making the Right Choice for Your Goal

Your choice of gasket should be dictated by the most critical demand of your application.

- If your primary focus is preventing contamination: The inert, non-toxic, and FDA-compliant nature of PTFE envelope gaskets makes them the standard for the food, pharmaceutical, and biotechnology industries.

- If your primary focus is resisting aggressive chemicals: Their near-universal chemical resistance is essential for ensuring safety and equipment longevity in chemical processing and petrochemical plants.

- If your primary focus is sealing fragile or uneven flanges: The combination of a soft PTFE face and a compressible core is ideal for protecting glass-lined reactors, older equipment, or other surfaces that cannot withstand high bolt loads.

Ultimately, the PTFE envelope gasket is a high-performance sealing solution engineered to succeed where lesser materials would quickly fail from chemical attack or contamination.

Summary Table:

| Industry | Primary Application | Key Benefit |

|---|---|---|

| Chemical & Petrochemical | Sealing flanges, reactors, pressure vessels | Unmatched chemical inertness against acids and solvents |

| Pharmaceutical & Food | Sanitary equipment, bioprocessing systems | High-purity, non-toxic, FDA-compliant |

| Semiconductor & High-Purity | Sensitive manufacturing processes | Prevents contamination in clean environments |

| General Industrial | Piping, pumps, valves, aerospace | Reliable barrier against liquids and contaminants |

Need a reliable sealing solution for your critical application? KINTEK specializes in manufacturing high-performance PTFE components, including custom envelope gaskets, seals, liners, and labware. We serve the semiconductor, medical, laboratory, and industrial sectors with precision production from prototypes to high-volume orders. Contact us today to discuss how our PTFE solutions can enhance your process safety and efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems