In essence, a PTFE reducing flange is a specialized connector used in industrial piping systems to create a secure, leak-proof join between two pipes of different diameters. Its primary function is to facilitate a change in pipe size while ensuring the integrity and performance of the entire system, particularly in demanding environments.

While any reducing flange connects pipes of different sizes, a PTFE-specific flange is chosen when the system demands exceptional chemical resistance, high purity, and non-stick properties that conventional materials like steel or other plastics cannot deliver.

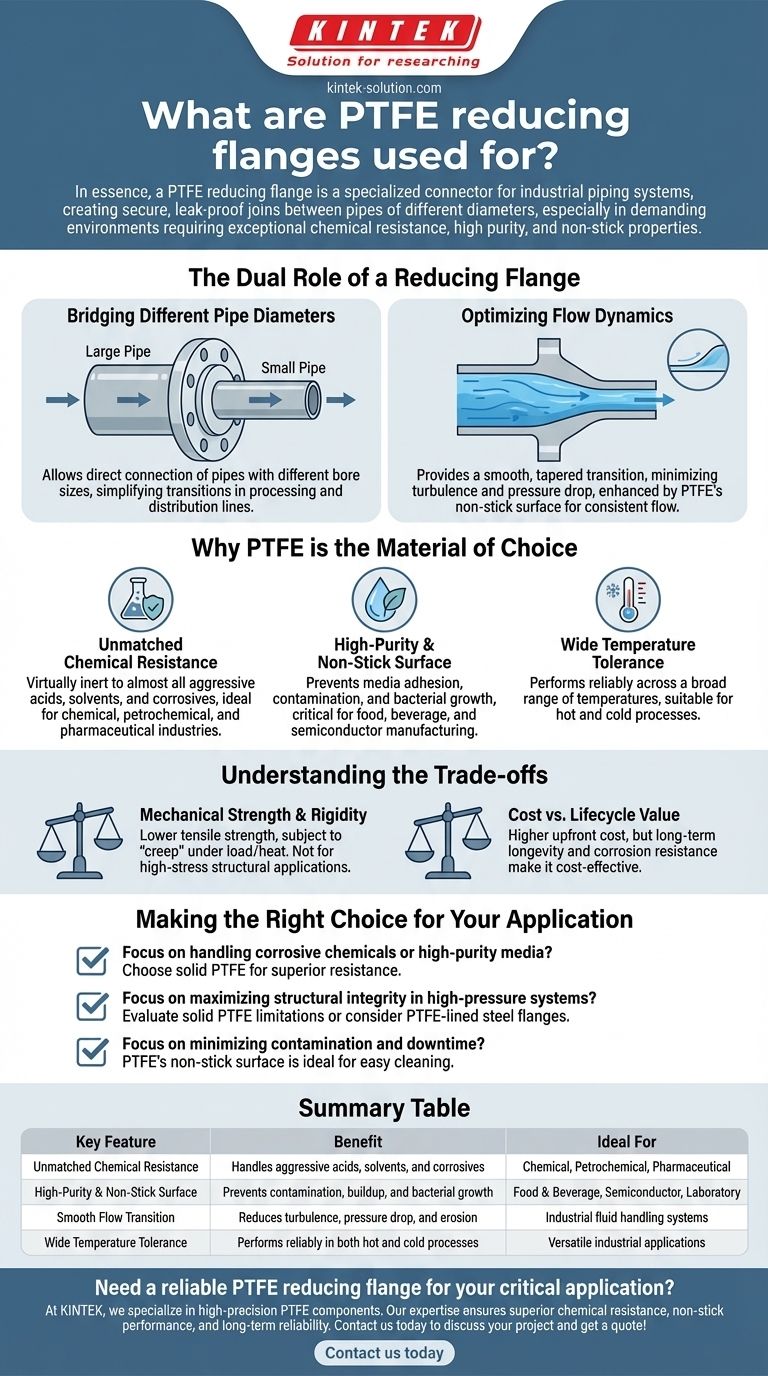

The Dual Role of a Reducing Flange

A reducing flange serves two distinct but related purposes within a fluid handling system. It is not just a connector, but a critical component for system optimization.

Bridging Different Pipe Diameters

The most obvious function is mechanical. The flange has two different nominal bore sizes, allowing a larger pipe to be connected directly to a smaller one, or vice-versa, without needing additional complex fittings.

This is essential for transitioning from main processing lines to smaller distribution or instrument lines while maintaining a single, integrated connection point.

Optimizing Flow Dynamics

A properly designed PTFE reducing flange provides a smooth, tapered transition between the two pipe sizes. This gradual change minimizes turbulence, pressure drop, and potential for erosion within the system.

The exceptionally smooth, non-stick surface of PTFE further enhances this effect, ensuring consistent flow rates and improving the overall efficiency of the industrial process.

Why PTFE is the Material of Choice

The selection of Polytetrafluoroethylene (PTFE) is a deliberate engineering decision driven by its unique material properties. These characteristics make it indispensable in specific industries.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals and solvents. This makes it the default choice for systems in the chemical, petrochemical, and pharmaceutical industries where aggressive or corrosive media would quickly degrade metal or lesser plastics.

High-Purity and Non-Stick Surface

The material's non-stick nature prevents media from adhering to the flange's surface. In food, beverage, and semiconductor manufacturing, this is critical for preventing contamination, bacterial growth, and product buildup, which simplifies cleaning cycles and ensures product purity.

Wide Temperature Tolerance

PTFE maintains its properties across a broad range of temperatures, making it suitable for processes involving both hot and cold fluids. This versatility allows it to perform reliably where other polymers might become brittle or deform.

Understanding the Trade-offs

While powerful, PTFE is not a universal solution. An objective assessment requires understanding its limitations compared to metallic alternatives.

Mechanical Strength and Rigidity

PTFE is a relatively soft material compared to stainless steel. It has lower tensile strength and can be subject to "creep"—a slow deformation under sustained load, especially at elevated temperatures and pressures. This must be accounted for in high-stress structural applications.

Thermal Expansion

PTFE has a significantly higher coefficient of thermal expansion than metals. In systems with wide temperature fluctuations, bolt torquing procedures and flange design must accommodate this expansion and contraction to maintain a reliable seal.

Cost vs. Lifecycle Value

The upfront cost of a solid PTFE flange may be higher than a standard metal flange. However, its longevity and resistance to corrosion in harsh environments often make it far more cost-effective over the lifecycle of the system by eliminating the need for frequent replacement.

Making the Right Choice for Your Application

Your final decision should be based on the specific demands of your system.

- If your primary focus is handling corrosive chemicals or high-purity media: The inert, non-stick nature of PTFE makes it the superior choice over most metals or other plastics.

- If your primary focus is maximizing structural integrity in a high-pressure system: You must carefully evaluate if solid PTFE's mechanical properties are sufficient, or if a PTFE-lined steel flange offers a better balance of chemical resistance and strength.

- If your primary focus is minimizing contamination and operational downtime: PTFE's non-stick surface is ideal, as it reduces product buildup and simplifies cleaning cycles in food, beverage, and pharmaceutical lines.

Ultimately, choosing a PTFE reducing flange is an investment in long-term system reliability and purity where standard materials would fail.

Summary Table:

| Key Feature | Benefit | Ideal For |

|---|---|---|

| Unmatched Chemical Resistance | Handles aggressive acids, solvents, and corrosives | Chemical, Petrochemical, Pharmaceutical |

| High-Purity & Non-Stick Surface | Prevents contamination, buildup, and bacterial growth | Food & Beverage, Semiconductor, Laboratory |

| Smooth Flow Transition | Reduces turbulence, pressure drop, and erosion | Industrial fluid handling systems |

| Wide Temperature Tolerance | Performs reliably in both hot and cold processes | Versatile industrial applications |

Need a reliable PTFE reducing flange for your critical application?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, labware, and custom flanges—for semiconductor, medical, laboratory, and industrial industries. Our expertise ensures your system benefits from superior chemical resistance, non-stick performance, and long-term reliability.

Whether you require prototypes or high-volume orders, we deliver solutions tailored to your exact needs.

Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are some modern applications of PTFE due to its electrical insulative properties? | High-Frequency & Extreme Environment Solutions

- What is the purpose of a PTFE liner in spherical bearings and rod ends? Achieve Zero-Maintenance, High-Precision Motion

- What are the key properties of PTFE material used in the spacer? Ensure Stability in Harsh Environments

- What are static applications and how are PTFE O-Rings used in them? Ensure Leak-Proof Seals in Demanding Environments

- What temperature range can PTFE balls withstand, and why is this beneficial? Unlock Extreme Thermal Performance

- Are PTFE butterfly valves suitable for high-pressure applications? Balancing Chemical Resistance & Pressure Limits

- How do cooling and lubrication affect the CNC machining of PTFE? Master Thermal Control for Precision

- What precautions should be taken when specifying PTFE Lip Seals? Ensure Long-Term Reliability for Your Application