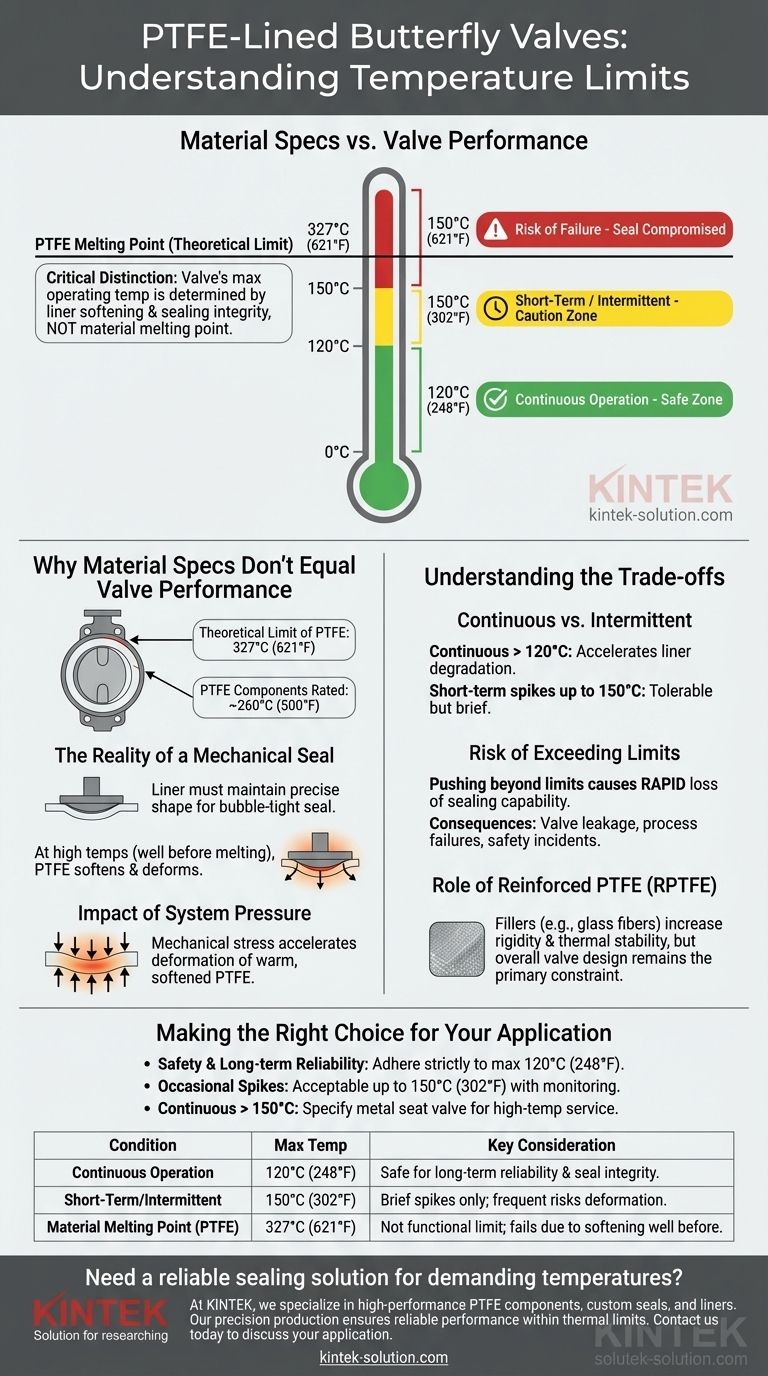

For practical, long-term industrial use, a PTFE-lined butterfly valve can typically withstand a continuous medium temperature of up to 120°C (248°F). While it can handle short-term exposure to temperatures as high as 150°C (302°F), exceeding these operational limits compromises the integrity of the valve's seal, even though the PTFE material itself has a much higher melting point.

The critical distinction to understand is that a valve's maximum operating temperature is not determined by the material's melting point, but by the temperature at which the material softens enough to compromise its mechanical function—in this case, its ability to create a perfect seal.

Why Material Specs Don't Equal Valve Performance

Many sources cite the high heat tolerance of Polytetrafluoroethylene (PTFE), which can be misleading when selecting a valve. The performance of the assembled valve is a more complex issue than the raw properties of its lining material.

The Theoretical Limit of PTFE

Pure PTFE has a very high melting point of 327°C (621°F). Components made from PTFE, such as rods or bellows, are often rated for service up to 260°C (500°F).

This high thermal stability is what makes PTFE a candidate for high-temperature applications in the first place.

The Reality of a Mechanical Seal

A butterfly valve's function depends entirely on the liner maintaining a precise shape to create a bubble-tight seal against the disc.

As temperatures rise, well before the melting point, the PTFE liner begins to soften and deform. This loss of rigidity is the true limiting factor.

Once the liner deforms, it can no longer press uniformly against the disc, resulting in an improper closure and significant leakage.

The Impact of System Pressure

This softening effect is amplified by the system's operating pressure. The mechanical stress from line pressure will cause a warm, softened PTFE liner to deform more easily than it would under no pressure.

Therefore, the safe operating temperature is a function of both the thermal and mechanical stresses placed on the valve assembly.

Understanding the Trade-offs

Choosing and operating a PTFE-lined valve requires acknowledging the sharp boundary between its normal operating window and its point of failure.

Continuous vs. Intermittent Operation

The distinction between continuous and short-term temperature limits is crucial for reliability.

Operating continuously at or above 120°C can accelerate liner degradation and lead to premature failure. Short-term spikes up to 150°C may be tolerable, but they should be infrequent and brief.

The Risk of Exceeding Temperature Limits

Pushing the valve beyond its recommended temperature range is not a gradual process. It can lead to a rapid loss of sealing capability.

The primary consequences are valve leakage and the inability to achieve proper shutoff, which can cause process failures or safety incidents.

The Role of Reinforced PTFE

Some manufacturers use fillers, such as glass fibers, to create reinforced PTFE (RPTFE). This can increase the material's rigidity and thermal stability.

While this may slightly improve performance at higher temperatures, you must always adhere to the specific temperature ratings provided by the valve manufacturer, as the overall valve design is still the primary constraint.

Making the Right Choice for Your Application

To ensure safety and reliability, you must select a valve based on its proven operational limits, not the theoretical properties of its materials.

- If your primary focus is safety and long-term reliability: Adhere strictly to a maximum continuous operating temperature of 120°C (248°F).

- If your process involves occasional, brief temperature spikes: A PTFE-lined valve may be acceptable up to 150°C (302°F), but this requires careful process control and monitoring.

- If your continuous operating temperature exceeds 150°C: A PTFE-lined butterfly valve is the wrong choice, and you should specify a valve with a metal seat designed for high-temperature service.

Ultimately, making an informed decision means trusting the valve's operational rating over the material's datasheet.

Summary Table:

| Condition | Maximum Temperature | Key Consideration |

|---|---|---|

| Continuous Operation | 120°C (248°F) | Safe for long-term reliability and seal integrity |

| Short-Term/Intermittent | 150°C (302°F) | Brief spikes only; frequent use risks deformation |

| Material Melting Point (PTFE) | 327°C (621°F) | Not the functional limit; valve fails due to softening well before this point |

Need a reliable sealing solution for demanding temperatures?

At KINTEK, we specialize in manufacturing high-performance PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your components perform reliably within their specified thermal limits, preventing costly downtime and failures.

Whether you require prototypes or high-volume orders, we provide custom fabrication tailored to your exact operational needs.

Contact us today to discuss your application and ensure optimal valve performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How do PTFE lined butterfly valves enhance safety in industrial settings? Prevent Leaks and Corrosion

- Why might PTFE envelope gaskets be preferred over pure PTFE gaskets in ISO tank applications? Ensure Reliable Transport of Sensitive Cargo

- Why are multi-axis machines recommended for Teflon CNC machining? Solve Deformation & Heat Issues

- What makes PTFE the preferred choice for high-speed rotary shaft seals? Unmatched Performance in Demanding Applications

- What are Teflon sheets and what are they made of? The Ultimate Guide to PTFE Properties

- What factors should be considered when selecting an expanded PTFE gasket? Optimize Your Seal for Performance

- What makes PTFE V-rings effective seals? A Guide to Robust, Low-Friction Sealing

- What are the key properties and applications of PEEK material? Unmatched Performance for Extreme Environments