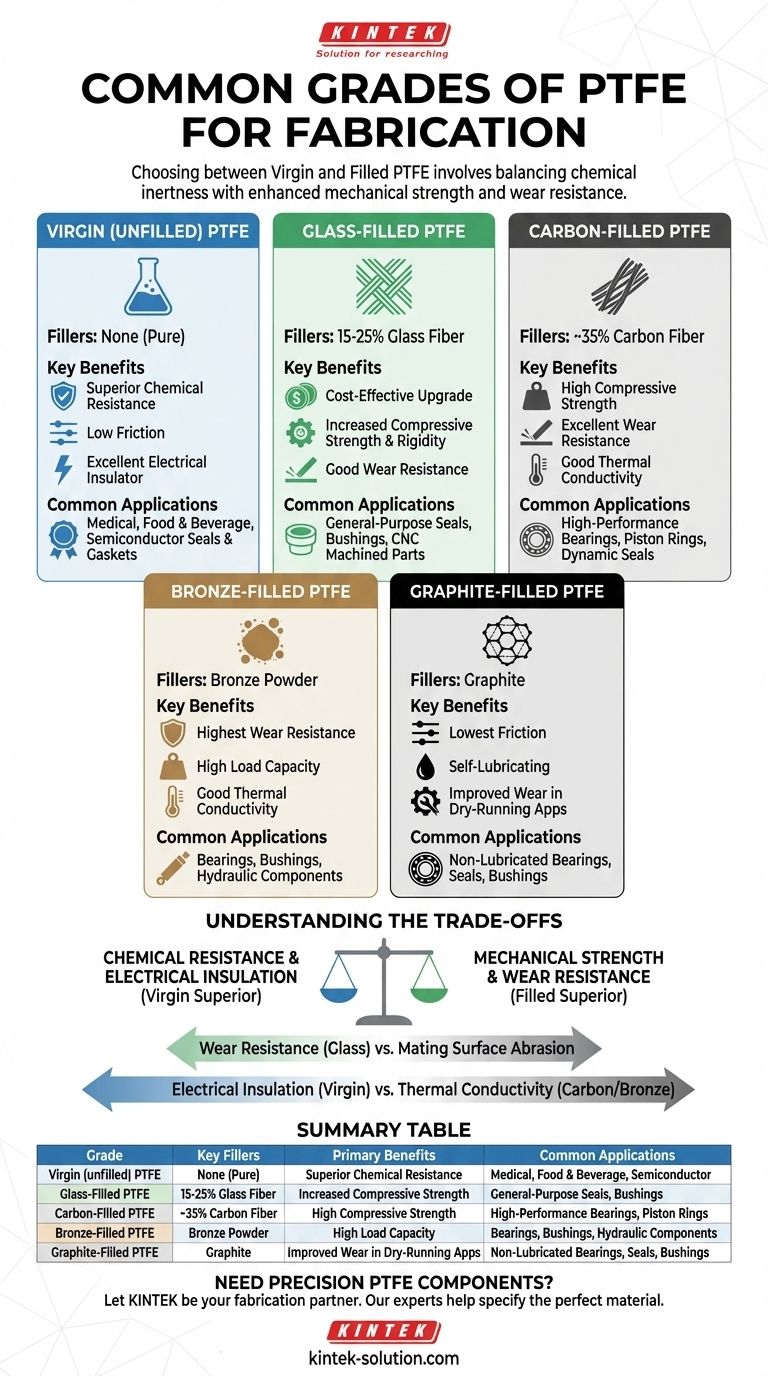

To fabricate parts, the most common grades of Polytetrafluoroethylene (PTFE) are virgin (unfilled) PTFE and various filled grades. Fillers like glass, carbon, and bronze are added to the PTFE base to enhance specific mechanical properties such as compressive strength, wear resistance, and dimensional stability, which are inherently limited in its pure form.

The core decision in selecting a PTFE grade is balancing the exceptional chemical, thermal, and electrical properties of virgin PTFE against the superior mechanical strength and wear resistance offered by filled grades. The filler you choose is determined entirely by the mechanical demands of your application.

The Foundation: Virgin (Unfilled) PTFE

Virgin PTFE is pure, unadulterated Polytetrafluoroethylene. It serves as the baseline from which all other grades are derived.

Key Properties

Virgin PTFE is prized for its nearly universal chemical inertness, extremely low coefficient of friction, and excellent performance at both high and low temperatures. It is also a superb electrical insulator.

Common Applications

Its purity makes it ideal for applications in the medical, food and beverage, and semiconductor industries. It's commonly used for seals, gaskets, packings, and bushings where chemical resistance is more critical than mechanical load.

Enhancing Mechanical Properties: Common PTFE Fillers

While virgin PTFE has remarkable properties, it is mechanically soft and can deform under load (a phenomenon known as "creep"). Fillers are added to create composite materials that overcome these limitations.

Glass-Filled PTFE

This is one of the most common and cost-effective filled grades. It typically contains between 15% and 25% glass fiber.

Adding glass fiber significantly increases compressive strength and rigidity. It also dramatically improves wear resistance compared to virgin PTFE.

It's a workhorse material for common seals, bushings, and components requiring higher mechanical strength and dimensional stability, especially in CNC machining.

Carbon-Filled PTFE

Carbon, often in powder or fiber form, is added to enhance mechanical and thermal properties. A common blend is 35% carbon fiber.

This grade offers excellent compressive strength, hardness, and wear resistance. It also provides good thermal conductivity, which helps dissipate heat in high-speed applications.

Carbon-filled PTFE is frequently used for high-performance bearings, piston rings, and seals in dynamic applications, particularly where chemical compatibility is still required.

Bronze-Filled PTFE

Bronze powder is mixed with PTFE to create a material with high compressive strength and excellent wear characteristics.

This grade has one of the highest wear resistances and can tolerate high loads. It also possesses better thermal conductivity than most other grades.

Its strength makes it ideal for bearings, bushings, and hydraulic system components. However, its chemical resistance is limited in the presence of acids and alkalis.

Graphite-Filled PTFE

Graphite is a self-lubricating filler that enhances PTFE's already low friction. It is often combined with other fillers, like carbon.

The primary benefit is a further reduction in the coefficient of friction and improved wear properties, especially in dry-running applications.

This grade is excellent for non-lubricated bearings, seals, and bushings where minimizing friction and wear is the top priority.

Understanding the Trade-offs

Choosing a filled PTFE grade is always an exercise in balancing competing requirements. Adding a filler to improve one property almost always compromises another.

Chemical Resistance vs. Strength

The primary trade-off is between chemical resistance and mechanical strength. While all PTFE grades have good chemical resistance, virgin PTFE is superior. Fillers can be attacked by certain chemicals that pure PTFE would resist.

Wear Resistance vs. Mating Surfaces

Fillers like glass fiber dramatically improve the wear resistance of the PTFE part itself but can be abrasive to the mating surface, especially softer metals. Softer fillers like graphite are much gentler.

Electrical Insulation vs. Thermal Conductivity

Virgin PTFE is an excellent electrical insulator. Adding conductive fillers like carbon or bronze significantly reduces its insulating properties but improves its ability to dissipate heat. This is a critical consideration for electrical versus high-speed mechanical applications.

Making the Right Choice for Your Goal

Your application's primary requirement should guide your material selection.

- If your primary focus is chemical purity or electrical insulation: Choose virgin (unfilled) PTFE for its unmatched inertness and dielectric strength.

- If your primary focus is general-purpose mechanical strength and rigidity: Choose glass-filled PTFE as the most common and cost-effective upgrade.

- If your primary focus is high-load capacity and wear resistance: Choose bronze-filled or carbon-filled PTFE for their superior compressive strength.

- If your primary focus is the lowest possible friction in a dynamic seal: Choose a graphite-filled or a carbon/graphite blend for its self-lubricating properties.

Ultimately, understanding the function of each filler empowers you to select the precise grade that meets your component's performance demands.

Summary Table:

| Grade | Key Fillers | Primary Benefits | Common Applications |

|---|---|---|---|

| Virgin PTFE | None (Pure) | Superior chemical resistance, low friction, excellent electrical insulator | Medical, food & beverage, semiconductor seals & gaskets |

| Glass-Filled PTFE | 15-25% Glass Fiber | Cost-effective, increased compressive strength & rigidity, good wear resistance | General-purpose seals, bushings, CNC machined parts |

| Carbon-Filled PTFE | ~35% Carbon Fiber | High compressive strength, excellent wear resistance, good thermal conductivity | High-performance bearings, piston rings, dynamic seals |

| Bronze-Filled PTFE | Bronze Powder | Highest wear resistance, high load capacity, good thermal conductivity | Bearings, bushings, hydraulic components |

| Graphite-Filled PTFE | Graphite | Lowest friction, self-lubricating, improved wear in dry-running apps | Non-lubricated bearings, seals, bushings |

Need Precision PTFE Components?

Let KINTEK be your fabrication partner. Selecting the right PTFE grade is critical for your component's performance. Our experts will help you navigate the trade-offs between chemical resistance, mechanical strength, and wear to specify the perfect material for your application.

We specialize in custom manufacturing PTFE seals, liners, labware, and other components for the semiconductor, medical, laboratory, and industrial sectors. From prototypes to high-volume production, we prioritize precision and quality.

Contact our team today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers