The primary advantage of Teflon bearings is their inherent self-lubricating nature, which dramatically reduces friction and eliminates the need for external grease or oil. This core property, combined with exceptional chemical resistance and wear performance, allows them to outperform traditional metal bearings in environments where lubrication is difficult, undesirable, or impossible.

The choice between Teflon and metal bearings is not about which is universally superior, but about matching the material to the operational environment. Teflon excels in applications demanding low friction, chemical inertness, and maintenance-free operation, while metal often remains the choice for extremely high loads and speeds.

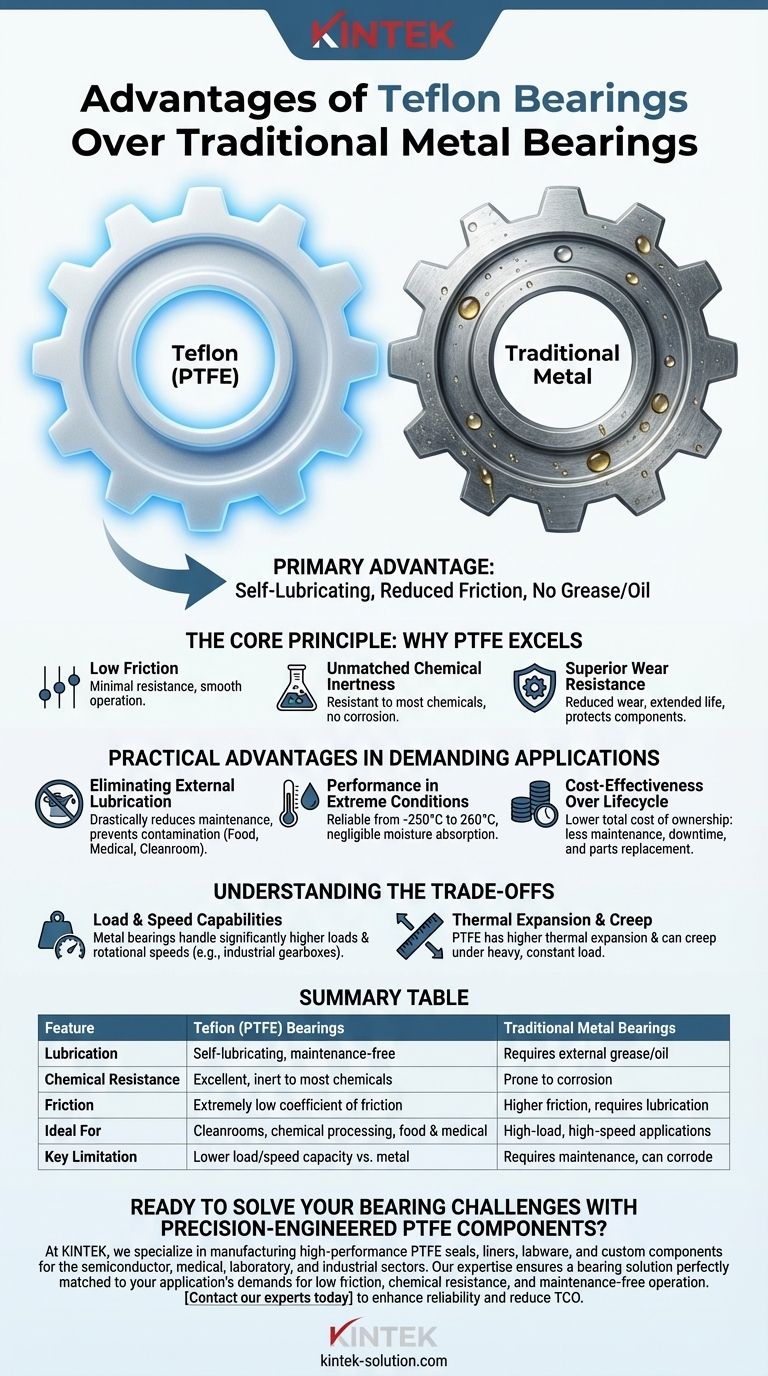

The Core Principle: Why PTFE Excels

The unique molecular structure of Polytetrafluoroethylene (PTFE), the material marketed as Teflon, is the source of its key advantages. It provides a set of properties that are fundamentally different from metals.

The Power of Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This means surfaces slide against each other with minimal resistance.

This property makes Teflon bearings self-lubricating. Unlike metal bearings that rely on a film of oil or grease, the lubrication is built into the material itself, ensuring consistent, smooth operation.

Unmatched Chemical Inertness

Teflon is exceptionally resistant to nearly all industrial chemicals, acids, and solvents. This chemical stability is a significant advantage over metal bearings.

Where a metal bearing would corrode and fail quickly in a harsh chemical environment, a Teflon bearing remains unaffected, ensuring operational reliability and longevity.

Superior Wear Resistance

The low-friction surface of Teflon significantly reduces wear on both the bearing and the mating shaft or component. This creates a system that lasts longer.

Because there is no abrasive metal-on-metal contact, service life is extended, and damage to critical, expensive components like shafts is minimized.

Practical Advantages in Demanding Applications

These fundamental properties translate into tangible benefits that solve common engineering challenges, particularly in demanding or sensitive environments.

Eliminating External Lubrication

The most significant operational advantage is the removal of any need for grease or oil. This drastically reduces maintenance requirements.

This also prevents contamination, making Teflon bearings ideal for applications in food processing, medical devices, and cleanroom environments where lubricants are prohibited.

Performance in Extreme Conditions

Teflon performs reliably across a very wide temperature range, from cryogenic lows (-250°C) to high heat (260°C).

It also features negligible moisture absorption, meaning its performance and dimensions remain stable in wet or humid conditions where metal could rust or seize.

Cost-Effectiveness Over the Lifecycle

While the initial component cost may be comparable, the total cost of ownership for Teflon bearings is often lower.

This is due to the elimination of lubrication costs, reduced maintenance labor, less equipment downtime, and a longer operational lifespan for both the bearing and its related parts.

Understanding the Trade-offs

No material is perfect for every situation. An objective analysis requires acknowledging the limitations where traditional metal bearings maintain an advantage.

Load and Speed Capabilities

Metal bearings, particularly roller element bearings, can typically handle significantly higher loads and rotational speeds than polymer bearings.

For high-stress applications like industrial gearboxes or large electric motors, the structural strength of steel is often non-negotiable.

Thermal Expansion

PTFE has a higher coefficient of thermal expansion than metals. This means it expands and contracts more with temperature changes.

Engineers must carefully account for this in the design phase to ensure proper clearances are maintained across the application's entire operating temperature range.

Susceptibility to Creep

Under a heavy, constant load, Teflon can be susceptible to "creep," which is a slow, permanent deformation over time.

In applications requiring extreme dimensional stability under high static loads, a metal bearing may be the more suitable choice.

Making the Right Choice for Your Application

Selecting the correct bearing material requires a clear understanding of your primary operational goal.

- If your primary focus is operation in corrosive or clean environments: Teflon is the superior choice due to its chemical inertness and self-lubricating properties.

- If your primary focus is managing extreme loads and rotational speeds: Traditional metal bearings remain the industry standard for their strength and rigidity.

- If your primary focus is reducing maintenance and total operating cost: Teflon offers a compelling advantage in moderate-load applications where frequent lubrication is costly or impractical.

Ultimately, choosing the right bearing is about aligning the material's inherent strengths with the specific demands of your engineering challenge.

Summary Table:

| Feature | Teflon (PTFE) Bearings | Traditional Metal Bearings |

|---|---|---|

| Lubrication | Self-lubricating, maintenance-free | Requires external grease/oil |

| Chemical Resistance | Excellent, inert to most chemicals | Prone to corrosion |

| Friction | Extremely low coefficient of friction | Higher friction, requires lubrication |

| Ideal For | Cleanrooms, chemical processing, food & medical | High-load, high-speed applications |

| Key Limitation | Lower load/speed capacity vs. metal | Requires maintenance, can corrode |

Ready to solve your bearing challenges with precision-engineered PTFE components?

At KINTEK, we specialize in manufacturing high-performance PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a bearing solution perfectly matched to your application's demands for low friction, chemical resistance, and maintenance-free operation.

Contact our experts today to discuss how our PTFE components can enhance your equipment's reliability and reduce your total cost of ownership.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining