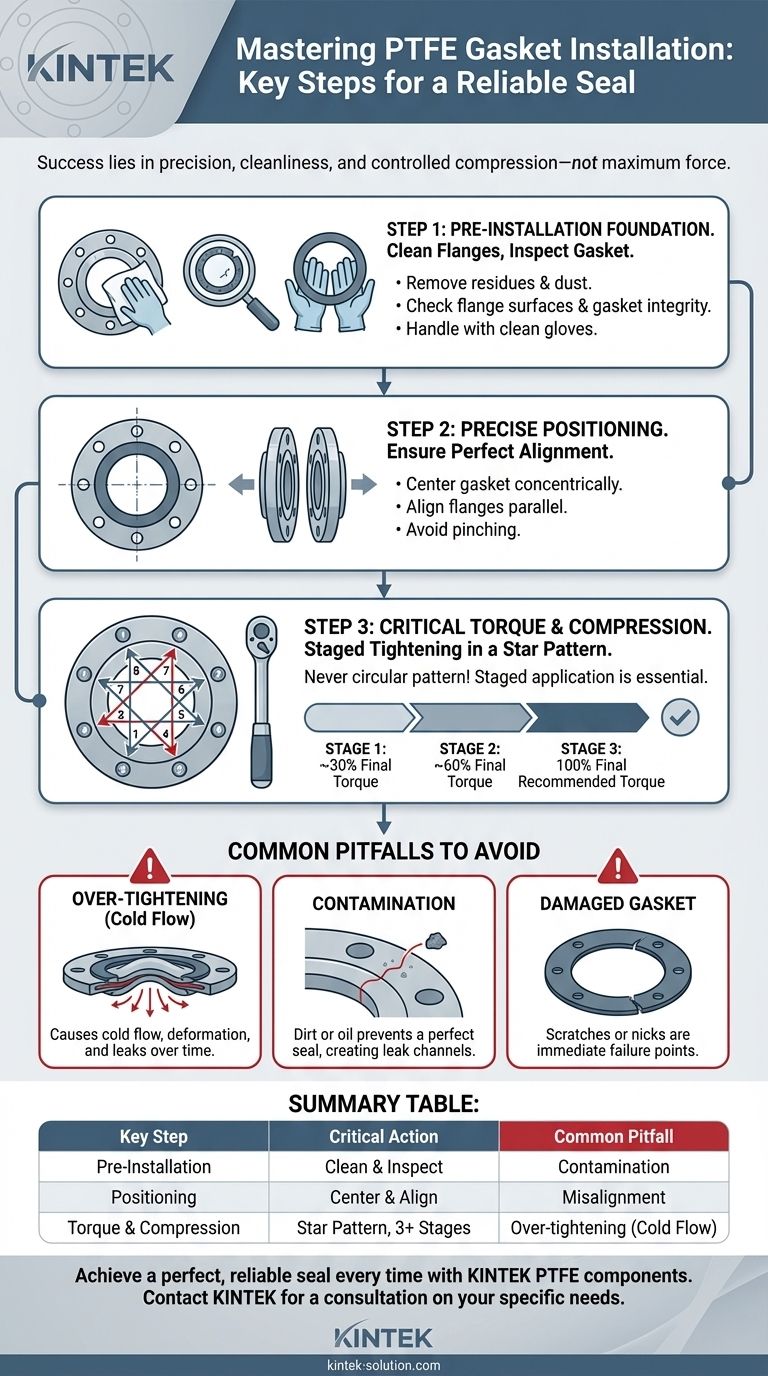

To properly install a PTFE gasket, you must execute a sequence of precise steps focused on cleanliness, alignment, and controlled compression. The essential process involves meticulously cleaning and inspecting the flange surfaces, handling the gasket carefully to prevent damage, ensuring it is perfectly centered, and then tightening the bolts incrementally in a star pattern to apply even, consistent pressure.

The key to a reliable seal with a PTFE gasket is not maximum force, but controlled, even compression. Unlike other materials, PTFE's tendency to "cold flow" means over-tightening is a primary cause of failure, making a precise, multi-stage torque procedure absolutely critical.

The Foundation: Pre-Installation Preparation

Success is determined long before the final torque is applied. Flawless preparation of both the gasket and the sealing surfaces is non-negotiable.

Inspect the Flange Surfaces

The flange faces must be perfectly clean and in good condition. Any foreign material creates a potential leak path.

Remove all dust, oily residues, metal swarf, or old gasket material from the sealing surfaces.

Check for any burrs, weld spatter, or deep scratches on the flange faces that could compromise the seal. The surfaces should be smooth and even.

Verify the Gasket Integrity

A new gasket is not automatically a perfect gasket. Always inspect it before installation.

Check the gasket for any defects, such as cuts, scratches, or deformities. A compromised surface cannot create a reliable seal.

Ensure you have the correct gasket size and style for the specific flange and application requirements.

Handle with Absolute Care

PTFE is a relatively soft material, and its surface is critical to its performance.

Always handle gaskets with clean gloves or tools to avoid contamination from oils or dirt on your hands.

Never use sharp tools that could scratch or gouge the gasket surface. Even a minor scratch can become a failure point under pressure.

The Core Procedure: Positioning and Assembly

Correct alignment ensures that the compressive load is distributed exactly where it needs to be.

Ensure Perfect Alignment

The gasket must be perfectly centered on the flange face. Misalignment leads to uneven compression and will likely cause a leak.

Carefully position the gasket to be concentric with the flange bore. For larger or more difficult installations, using alignment tools can be beneficial.

Assemble the Flanges

Once the gasket is in place, bring the mating flange into position carefully.

Ensure the flanges come together parallel to one another. Avoid scraping or pinching the gasket during this process.

The Critical Step: Torque and Compression

This is the stage where the unique properties of PTFE demand the most attention. The goal is even stress distribution.

Follow a Star or Crisscross Pattern

Never tighten bolts in a circular pattern. This creates uneven pressure points and can warp the flange or damage the gasket.

Always use a star or crisscross pattern to gradually and evenly draw the flanges together.

Apply Torque in Stages

Applying the final torque value in a single pass is a common and critical error.

Apply the torque in at least three distinct stages:

- First Pass: Tighten to approximately 30% of the final recommended torque.

- Second Pass: Tighten to approximately 60% of the final torque.

- Final Pass: Tighten to 100% of the final recommended torque value.

A final check pass, again in a star pattern, is often recommended to ensure all bolts are at the final torque.

Common Pitfalls That Compromise a Seal

Understanding why PTFE gaskets fail is key to preventing those failures. The material's unique behavior is the primary factor.

The Danger of Over-tightening (Cold Flow)

The most common mistake is treating PTFE like a harder gasket material and applying too much force.

PTFE is susceptible to cold flow, or creep, where the material deforms and moves away from the pressure source over time.

Over-tightening crushes the gasket, causing it to extrude or thin out. This reduces the sealing stress on the gasket, creating a leak path hours or days after the initial installation.

The Impact of Contamination

Any debris, no matter how small, can compromise the seal.

A piece of dirt, a metal filing, or an oily residue prevents the gasket from making perfect contact with the flange face, creating a microscopic channel for leaks.

Using Damaged or Incorrect Gaskets

Installing a gasket that is already scratched or nicked is setting the joint up for failure from the start.

Likewise, using the wrong size or type of PTFE for the application's pressure, temperature, or chemical environment will lead to premature failure.

Making the Right Choice for Your Goal

Your installation procedure should reflect the criticality of the application.

- If your primary focus is maximum long-term reliability in critical service: Follow every step precisely, use a calibrated torque wrench, and allow time for the gasket to settle before a final torque check pass.

- If your primary focus is standard maintenance: Do not skip the cleaning and inspection steps. A star pattern and staged tightening are still essential for a dependable seal.

- If you are troubleshooting a recurring leak: Re-evaluate the entire process, paying special attention to flange surface quality and the possibility of over-tightening during previous installations.

Ultimately, a successful PTFE gasket installation relies on precision and a methodical approach, not brute force.

Summary Table:

| Key Installation Step | Critical Action | Common Pitfall to Avoid |

|---|---|---|

| Pre-Installation | Clean flanges, inspect gasket for damage. | Contamination from dirt, oils, or sharp tools. |

| Positioning | Center gasket perfectly, align flanges parallel. | Misalignment causing uneven compression. |

| Torque & Compression | Tighten bolts in a star pattern, in 3+ stages (30%, 60%, 100%). | Over-tightening, which causes PTFE cold flow and seal failure. |

Achieve a perfect, reliable seal every time with KINTEK PTFE components.

Our high-precision PTFE seals, gaskets, liners, and custom labware are manufactured to the highest standards for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a prototype or high-volume production, our expertise ensures your critical applications are protected from leaks and failure.

Contact KINTEK today for a consultation on your specific PTFE component needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability