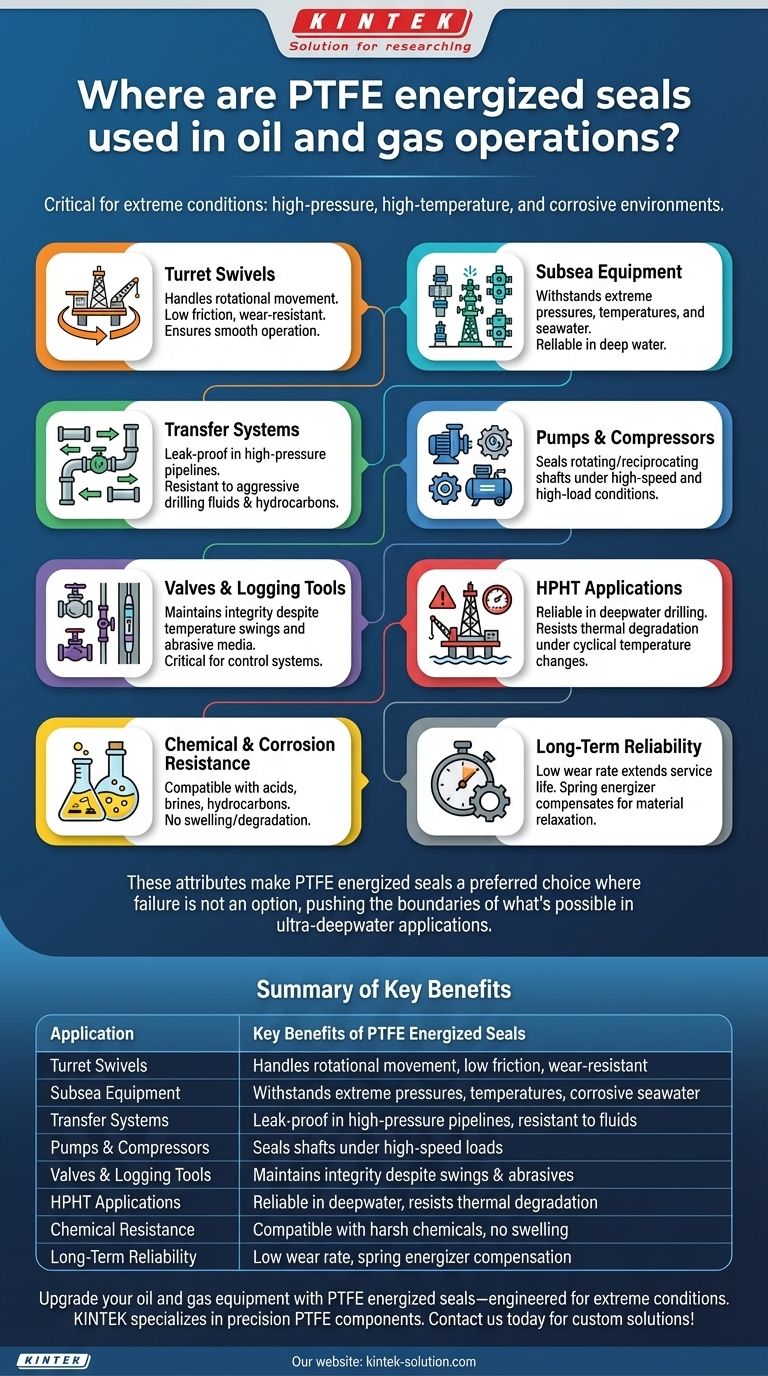

PTFE energized seals, particularly spring energized PTFE seals, are critical components in oil and gas operations due to their ability to withstand extreme conditions. These seals are used in high-pressure, high-temperature, and corrosive environments, ensuring leak-tight performance in equipment like pumps, compressors, subsea systems, and turret swivels. Their compatibility with aggressive chemicals and wide temperature ranges makes them indispensable for maintaining sealing integrity in demanding applications such as valves, logging tools, and transfer systems. The oil and gas industry relies on these seals for long-term reliability under harsh operational conditions.

Key Points Explained:

-

Turret Swivels

- PTFE energized seals are used in turret swivels to handle rotational movement while maintaining a seal under high pressure and corrosive conditions.

- Their low friction and wear resistance ensure smooth operation in dynamic applications.

-

Subsea Equipment

- Subsea environments demand seals that can withstand extreme pressures, temperatures, and exposure to seawater and hydrocarbons.

- PTFE seals provide reliable performance in subsea connectors, Christmas trees, and blowout preventers (BOPs).

-

Transfer Systems

- In fluid transfer systems, these seals prevent leaks in high-pressure pipelines and manifolds.

- Their chemical resistance is crucial for handling aggressive drilling fluids and hydrocarbons.

-

Pumps and Compressors

- PTFE seals are widely used in centrifugal pumps, reciprocating compressors, and hydraulic systems.

- They excel in sealing rotating or reciprocating shafts, even under high-speed and high-load conditions.

-

Valves and Logging Tools

- Critical for sealing valves in wellheads, choke valves, and control systems.

- Logging tools benefit from their ability to maintain integrity despite temperature swings and abrasive media.

-

High-Pressure and High-Temperature (HPHT) Applications

- PTFE seals perform reliably in HPHT conditions, common in deepwater drilling and production.

- Their thermal stability prevents degradation under cyclical temperature changes.

-

Chemical and Corrosion Resistance

- Compatible with acids, brines, and hydrocarbons, making them ideal for corrosive environments.

- Unlike elastomeric seals, PTFE does not swell or degrade when exposed to harsh chemicals.

-

Long-Term Reliability

- PTFE’s low wear rate ensures extended service life, reducing maintenance downtime.

- The spring energizer compensates for material relaxation, maintaining consistent sealing force.

These attributes make PTFE energized seals a preferred choice for oil and gas operations, where failure is not an option. Have you considered how advancements in seal materials could further enhance performance in ultra-deepwater applications? Such innovations continue to push the boundaries of what’s possible in this demanding industry.

Summary Table:

| Application | Key Benefits of PTFE Energized Seals |

|---|---|

| Turret Swivels | Handles rotational movement, low friction, wear-resistant |

| Subsea Equipment | Withstands extreme pressures, temperatures, and corrosive seawater |

| Transfer Systems | Leak-proof in high-pressure pipelines, resistant to drilling fluids |

| Pumps & Compressors | Seals rotating/reciprocating shafts under high-speed loads |

| Valves & Logging Tools | Maintains integrity despite temperature swings and abrasives |

| HPHT Applications | Reliable in deepwater drilling, resists thermal degradation |

| Chemical Resistance | Compatible with acids, brines, hydrocarbons—no swelling/degradation |

| Long-Term Reliability | Low wear rate, spring energizer compensates for material relaxation |

Upgrade your oil and gas equipment with PTFE energized seals—engineered for extreme conditions. KINTEK specializes in precision PTFE components (seals, liners, labware) for semiconductor, medical, and industrial applications. Whether you need prototypes or high-volume orders, our custom fabrication ensures optimal performance. Contact us today to discuss your sealing challenges!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions