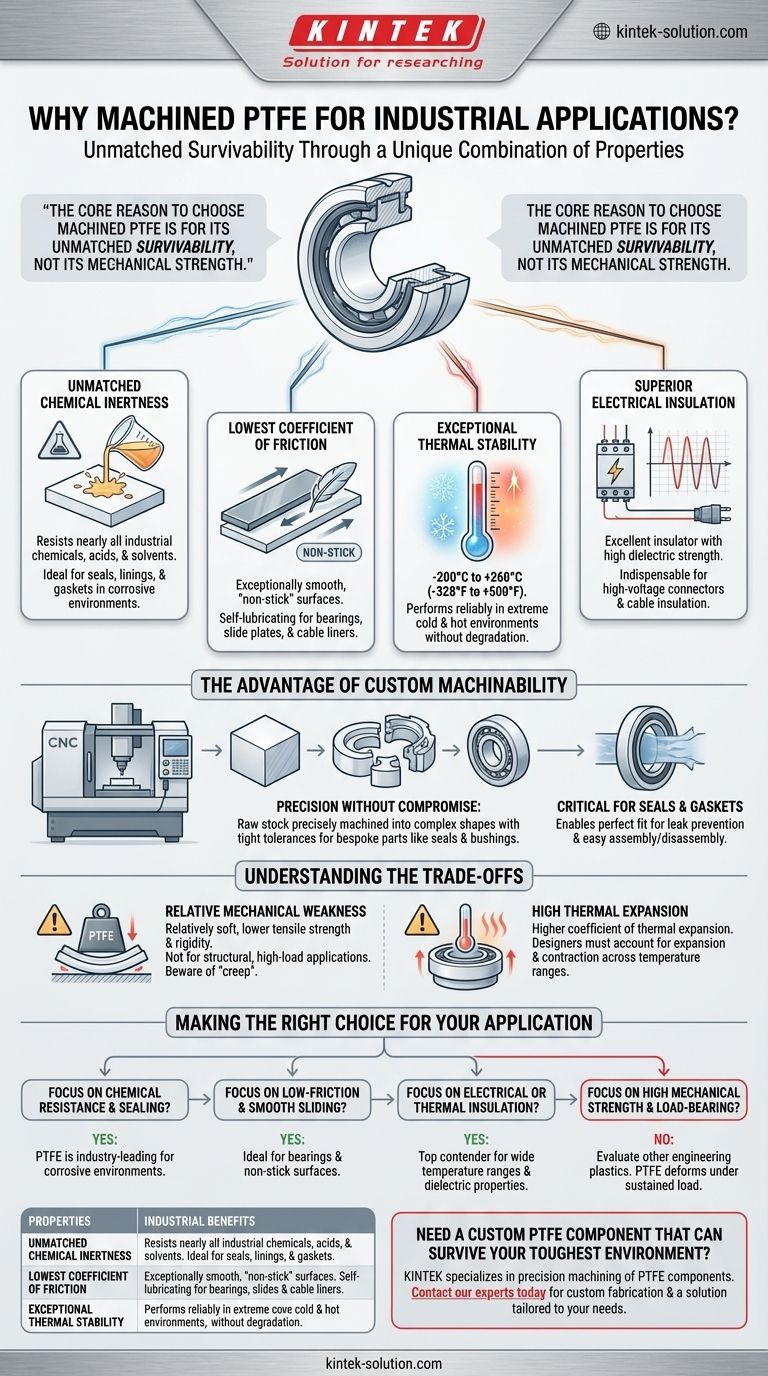

In short, machined Polytetrafluoroethylene (PTFE) is uniquely suitable for industrial applications due to its rare combination of four key properties. It offers near-total chemical inertness, an extremely low coefficient of friction, exceptional stability across a wide temperature range, and excellent electrical insulation. These characteristics allow it to perform reliably in harsh operating conditions where most other materials, including metals and other plastics, would quickly fail.

The core reason to choose machined PTFE is for its unmatched survivability, not its mechanical strength. It excels in extreme chemical, thermal, and low-friction environments that would corrode, melt, or seize other materials, making it a premier problem-solving polymer for specialized components.

The Core Properties Driving Industrial Adoption

The value of PTFE in industrial settings comes from a specific set of performance characteristics that are difficult to find in a single material. Understanding these properties explains its widespread use in critical applications.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, acids, and solvents. This high level of corrosion resistance makes it an ideal material for components used in chemical processing.

This property is why PTFE is specified for gaskets, seals, and linings in pipes and vessels that handle aggressive fluids. It ensures system integrity and prevents contamination.

The Lowest Coefficient of Friction

Among all solid materials, PTFE has one of the lowest coefficients of friction. This means surfaces are exceptionally smooth and "non-stick," allowing parts to slide against each other with minimal energy loss or wear.

This self-lubricating nature is critical for applications like bearings, slide plates, and cable liners, where adding external lubrication is impractical or undesirable.

Exceptional Thermal Stability

PTFE maintains its key properties across an incredibly broad temperature range, typically from -200°C to +260°C (-328°F to +500°F).

It does not become brittle in cryogenic applications or degrade in high-heat processes where other polymers would melt. This makes it a reliable choice for components in both extreme cold and hot environments.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with a very high dielectric strength, meaning it can withstand high voltages without breaking down.

This makes it indispensable in the electronics and aerospace industries for manufacturing high-frequency connectors, cable insulation, and other insulative components where signal integrity is paramount.

The Advantage of Custom Machinability

Beyond its inherent properties, PTFE's suitability for machining is a key factor in its industrial use.

Precision Without Compromise

Raw PTFE stock can be precisely machined into complex, custom shapes and components with very tight dimensional tolerances.

This allows for the creation of bespoke parts like intricate seals, insulators, and bushings that are perfectly tailored to a specific piece of equipment.

Why This Matters for Seals and Gaskets

The ability to machine PTFE allows engineers to design seals and gaskets that provide a perfect fit for preventing leaks in critical systems.

Its non-stick surface also facilitates easier assembly and disassembly of parts, while its chemical resistance ensures the seal will not degrade when in contact with process fluids.

Understanding the Trade-offs

No material is perfect. A clear understanding of PTFE's limitations is essential for proper application and design.

Relative Mechanical Weakness

PTFE is a relatively soft material with lower tensile strength and rigidity compared to other engineering plastics like Nylon or PEEK. It is not designed for structural, high-load-bearing applications.

Under sustained compressive loads, especially at elevated temperatures, PTFE can deform or "creep." This must be accounted for in the design of components like seals and bearings.

High Thermal Expansion

PTFE has a higher coefficient of thermal expansion than many other engineering materials.

Designers must allow for this expansion and contraction in applications that operate across a wide temperature range to avoid part failure or binding.

Making the Right Choice for Your Application

To determine if machined PTFE is the correct material, you must align its strengths with the primary demands of your application.

- If your primary focus is chemical resistance and sealing: PTFE is an industry-leading choice for gaskets, liners, and seals in corrosive environments.

- If your primary focus is low-friction and smooth sliding: Machined PTFE is ideal for bearings, slide plates, and non-stick surfaces where external lubrication is undesirable.

- If your primary focus is electrical or thermal insulation: PTFE's stability across wide temperature ranges and its excellent dielectric properties make it a top contender.

- If your primary focus is high mechanical strength and load-bearing: You should evaluate other engineering plastics, as PTFE deforms under sustained load and is not a structural material.

Ultimately, you choose machined PTFE when performance in an extreme environment is the most critical factor for success.

Summary Table:

| Key Property | Industrial Benefit |

|---|---|

| Chemical Inertness | Resists nearly all acids, solvents, and corrosive fluids. |

| Low Coefficient of Friction | Provides self-lubrication for bearings and slide plates. |

| Wide Temperature Range | Performs reliably from -200°C to +260°C. |

| Excellent Electrical Insulation | Maintains signal integrity in high-voltage applications. |

Need a custom PTFE component that can survive your toughest environment?

KINTEK specializes in precision machining of PTFE components—like seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We deliver custom fabrication from prototypes to high-volume orders, ensuring your parts offer unmatched chemical resistance, thermal stability, and low friction.

Contact our experts today to discuss your specific requirements and get a solution tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What factors should be considered when selecting PTFE lip seals? Ensure Long-Term Reliability in Demanding Applications

- What makes PTFE suitable for custom industrial parts? Discover the Ideal Material for Harsh Environments

- What are the key considerations for PTFE lined butterfly valve installation? Protect Your Liner for a Leak-Proof Seal

- In what applications are PTFE oil seals particularly advantageous? Superior Performance in Extreme Conditions

- How does the high cycle life of PTFE diaphragm valves benefit pharmaceutical manufacturing? Boost Uptime & Purity

- How is PTFE utilized in the electrical and electronics industry? Unlock Superior Performance & Reliability

- What makes PTFE gaskets an ideal sealing material? Unmatched Chemical & Temperature Resistance

- How does the durability of Teflon sheets benefit printing operations? Boost Quality & Cut Costs